Ultrahigh pressure cross linked polyethylene insulated flexible direct-current optical fiber composite submarine cable

A cross-linked polyethylene and DC cable technology, applied in communication cables, cables, circuits, etc., can solve the problems of unsuitable seabed large drop laying, small transmission current, oil leakage and aging, etc., to save marine routing resources and improve work. Field strength, effect of reducing insulation thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

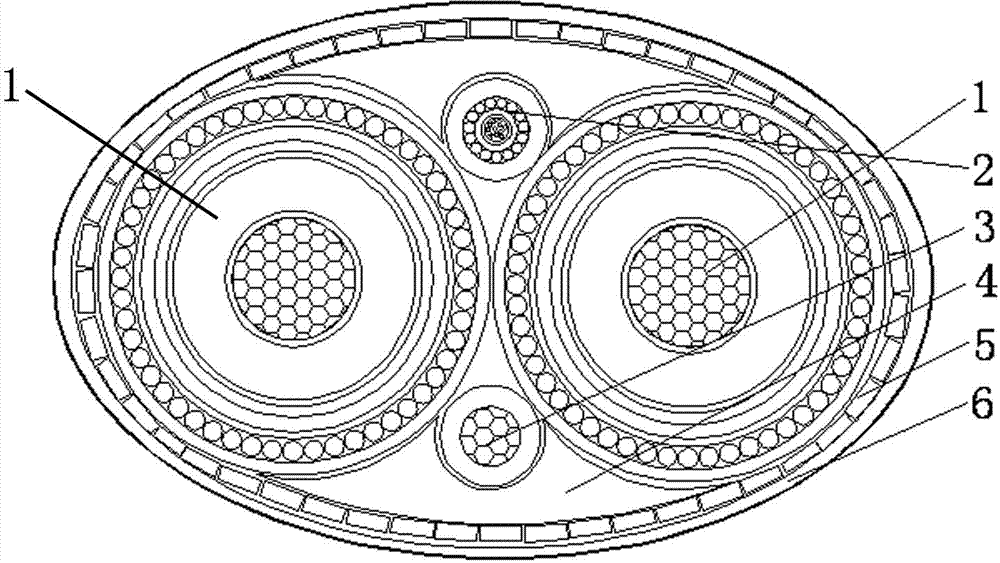

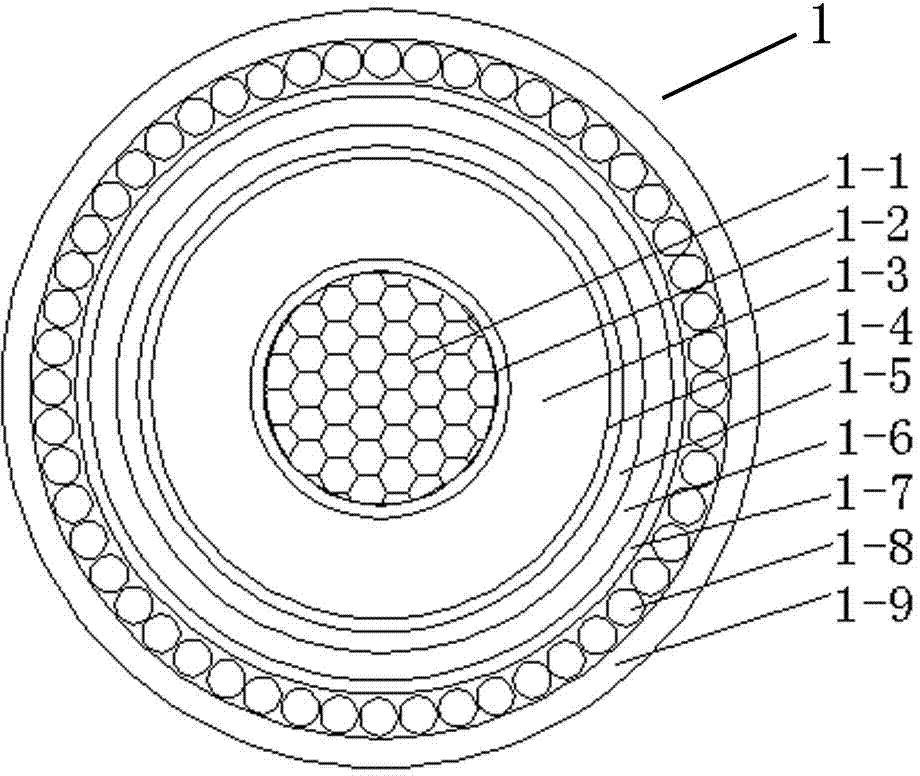

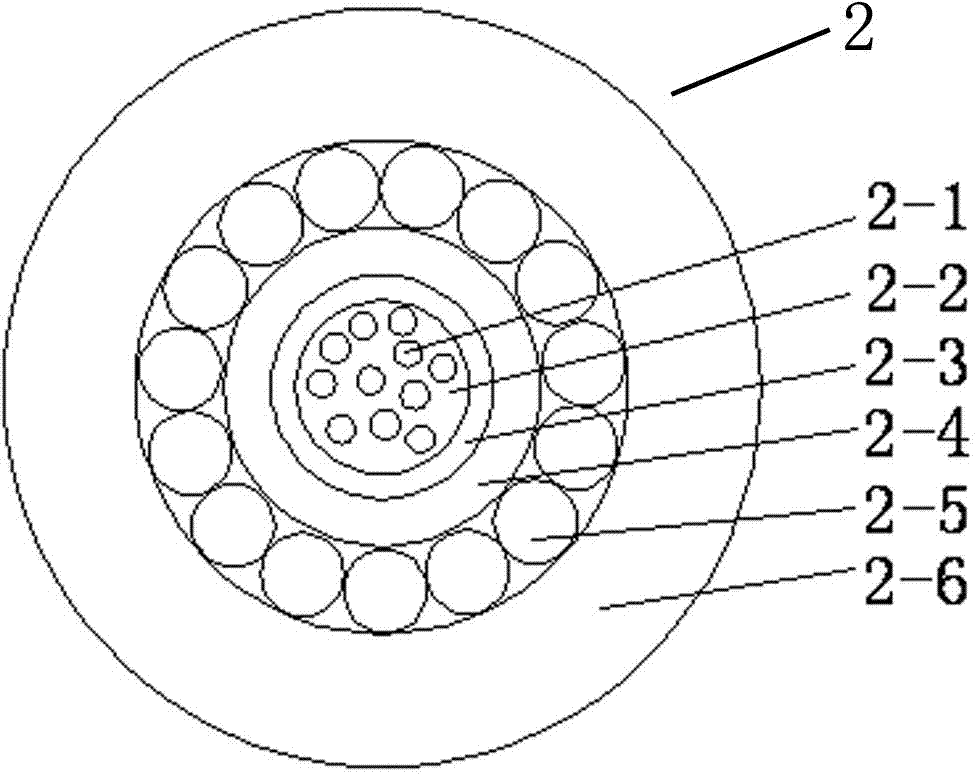

[0029] Refer to attached Figure 1~4 , the ultra-high voltage XLPE insulated flexible DC optical fiber composite submarine cable of the present invention includes a DC cable 1, an optical fiber unit 2, a ground feeder 3, a filling strip 4, a total armor layer 5 and an outer sheath 6, and the two DC cables 1 are respectively Placed on the left and right, respectively are the positive and negative DC cables, the optical fiber unit 2 is placed above the middle of the two DC cables 1, the grounding feeder 3 is placed below the middle of the two DC cables 1, and is cabled by pinto non-twisting ; The cabling gap is filled with arc-shaped filling strips 4; after the DC cable 1, the optical fiber unit 2 and the ground feeder 3 are cabled, the overall armor layer 5 is used for overall armor, and the surface of the overall armor layer 5 is composed of 1~3 Layers of polypropylene rope are wound to form the outer sheath 6, each layer of polypropylene rope is coated with anti-corrosion ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com