Automatic automobile plate spring forming heat treatment line and work method thereof

An automatic forming and auto sheet technology, which is applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of time-consuming manual loading and unloading, laborious work rhythm, and inability to close reed edges, so as to save work space and facilitate the output of workpieces Material, the effect of smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail now in conjunction with accompanying drawing.

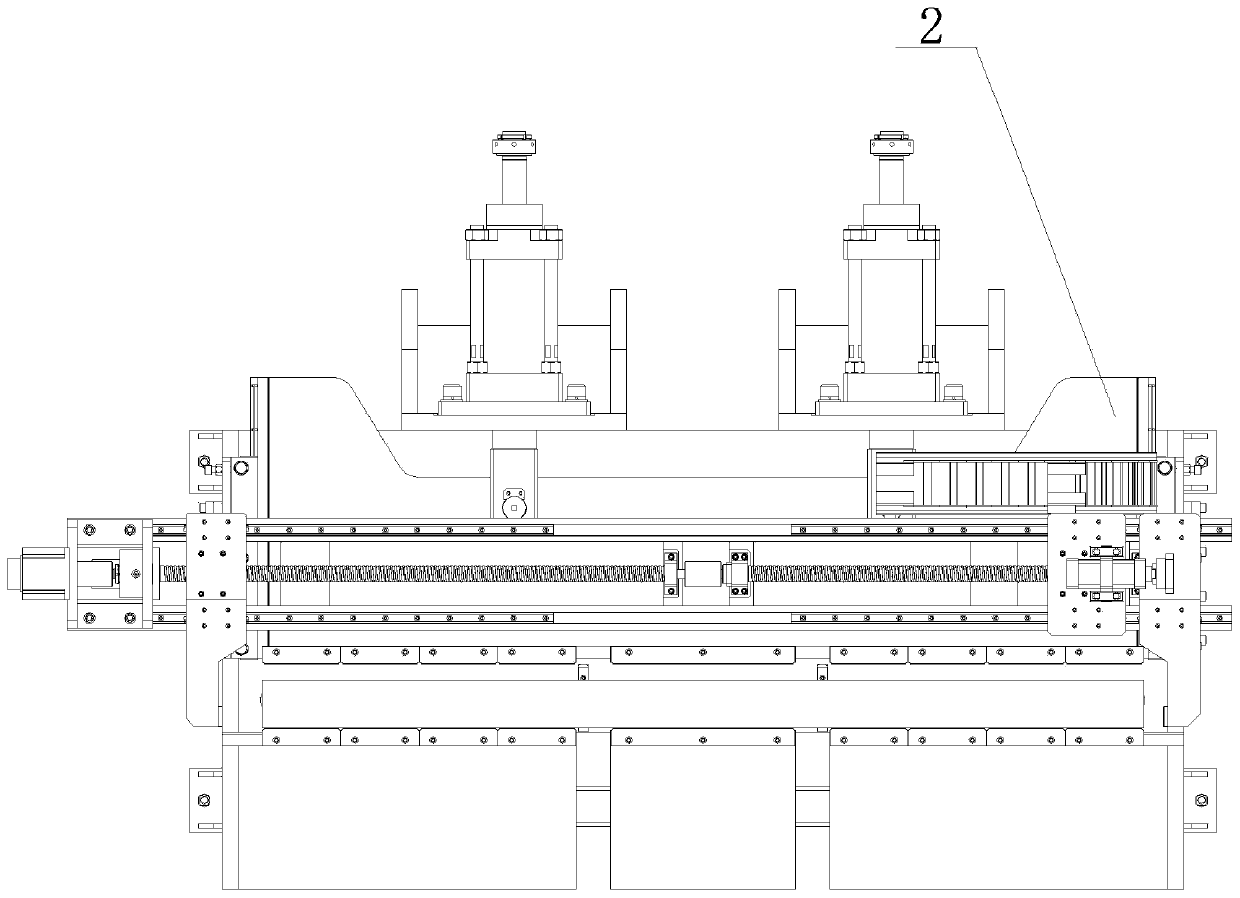

[0033] Such as Figure 1-7 , an automobile leaf spring automatic forming heat treatment line, comprising an automatic feeding device 1, a leaf spring quenching furnace 6, a leaf spring straightening machine 2, a leaf spring forming machine 3, a quenching device 4 and a tempering furnace 5, the production line The layout is arranged side by side in a "one" shape. This layout makes reasonable use of space and saves work space.

[0034] The automatic feeding device 1 is equipped with an electromagnetic sucker 11, and adopts the automatic centering feeding method. First, the electric hoist is used to drive the electromagnetic sucker 11 to complete the loading and unloading of the entire row of reeds, and then the centering mechanism 12 in front of the furnace aligns the ends of the reeds. Finally, the small step feeding mechanism 13 rotates the reeds one by one to the quenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com