Method for measuring and calculating sulfuric acid corrosion resisting equivalent of steel material

A corrosion-resistant and sulfuric acid-resistant technology, applied in the field of measuring the sulfuric acid dew point corrosion resistance of steel, can solve the problems of lack of accurate and unified composition control range and standards, long test period, sulfuric acid dew point corrosion, etc., and achieve significant economic benefits and efficiency. Social benefits, saving resources and energy consumption, and meeting the effect of corrosion resistance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The chemical composition of the known samples A1~A6 and the actual measured corrosion rate are shown in Table 1:

[0018]

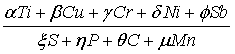

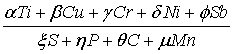

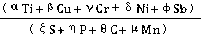

[0019] Let α=100, β=100, γ=100, δ=100, φ=1000, ζ=1000, η=500, θ=100, μ=10, respectively calculate the corrosion resistance equivalent of each sample:

[0020] Corrosion resistance equivalent A1= =1.915

[0021] In the same way, the corrosion resistance equivalent A2=2.012; A3=0.160; A4=2.966; A5=1.939; A6=4.476.

[0022] According to the corrosion resistance equivalent calculated above and the measured corrosion rate, linear regression is performed to obtain y'=8.6991x' -0.6353 , coefficient of determination R 2 =0.9639, after conversion, the equation is obtained: y=8.6991x -0.6353 , where x is the corrosion resistance equivalent of the sample to be tested under the same process conditions, and y is the annual corrosion rate calculated based on the composition (mm / year, mm / y).

Embodiment 2

[0024] The chemical composition of the known samples B1~B6 and the actual measured corrosion rate are shown in Table 2:

[0025]

[0026] Let α=120, β=120, γ=120, δ=120, φ=900, ζ=900, η=600, θ=120, μ=12, respectively calculate the corrosion resistance equivalent of each sample:

[0027] Corrosion resistance equivalent B1= =1.278

[0028] In the same way, the corrosion resistance equivalent B2=0.193; B3=4.882; B4=4.764; B5=4.170; B6=3.703.

[0029] According to the corrosion resistance equivalent calculated above and the measured corrosion rate, linear regression is performed to obtain y'=14.102x' -0.4003 , coefficient of determination R 2 =0.9760, after conversion, the equation is obtained: y=14.102x -0.4003 , where x is the corrosion resistance equivalent of the sample to be tested under the same process conditions, and y is the annual corrosion rate calculated based on the composition (mm / year, mm / y).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com