Valve body suitable for eccentric rotary regulating valve

An eccentric rotation, valve body technology, applied in valve details, valve device, valve shell structure, etc., can solve the problem of no breakthrough in transmission torque and flow capacity, and achieve the effect of a large number of teeth, reliable sealing, and increased stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be further described in detail below in conjunction with the description of the drawings and specific embodiments.

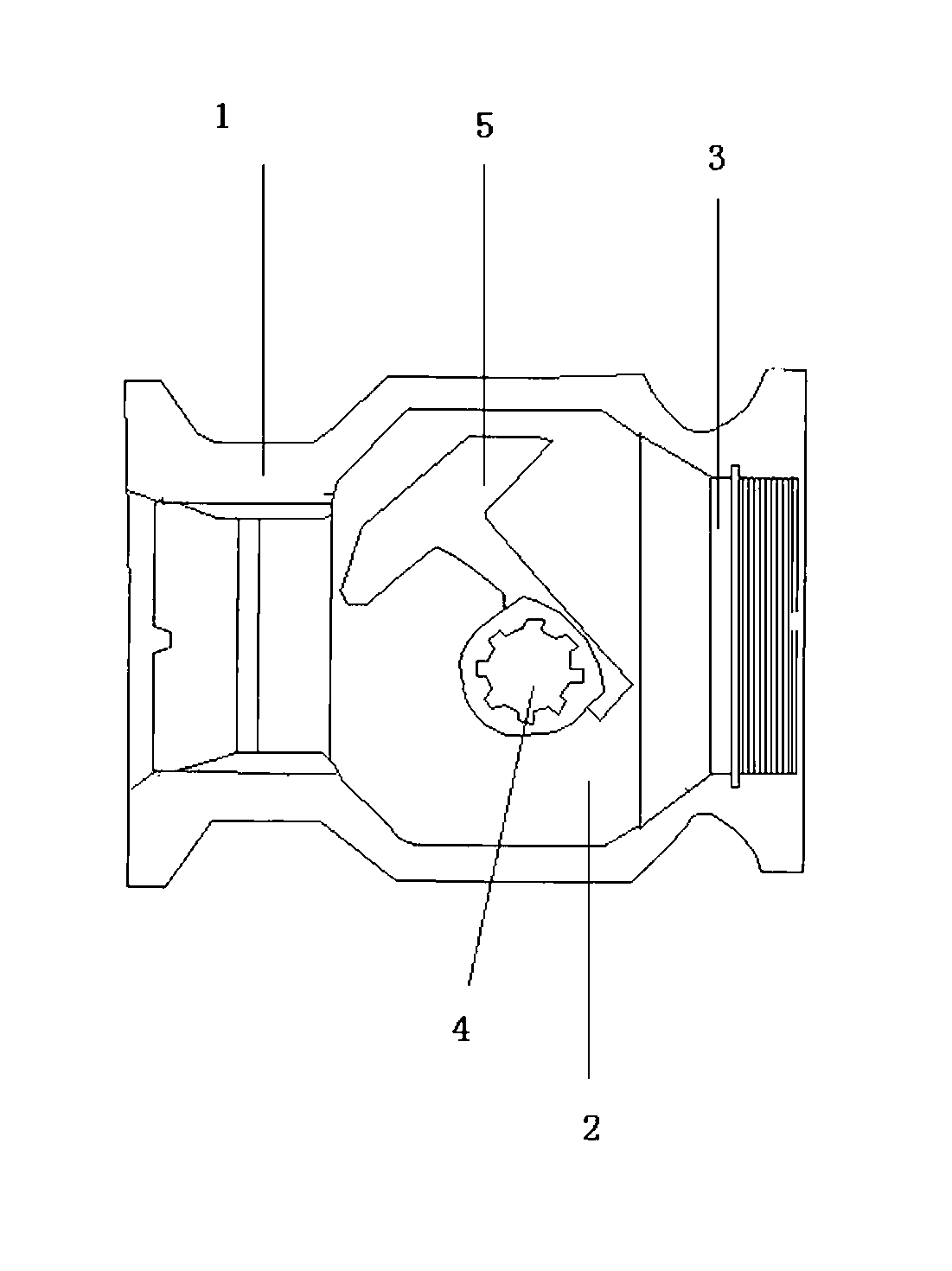

[0013] A valve body 1 suitable for a pneumatic eccentric rotary valve, the valve body 1 is provided with a valve core 2 and a valve seat 3 adjacent to the valve core 2; the valve body 1 is approximately cylindrical, and the center of the spherical surface of the valve core 2 is aligned An eccentric distance is designed between the rotation centers, and the running track is a cam-shaped curve. The valve core 2 is provided with a kneading arm 5 and a spline 4 connected with the kneading arm 5; the kneading arm 5 is an elastic kneading arm, and the spline 4 is preferably an involute spline. As a preference, the inner channel of the valve body 1 is a straight-through channel.

[0014] The operation process of the valve body suitable for pneumatic eccentric rotary valve is: when the valve core 2 is driven by the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com