Emptying bin gate

A silo and valve technology, which is applied to the valve operation/release device, lift valve, valve details, etc., can solve the problems of inconvenient discharge of the silo and affect the production operation, and achieve the effect of labor-saving operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

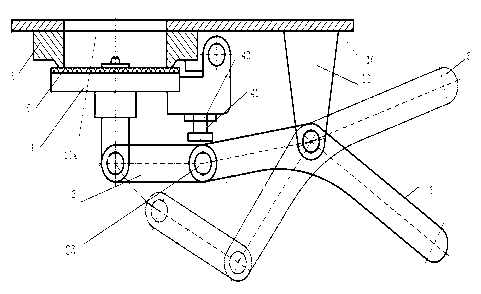

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0012] The discharge bin door is arranged at the bottom 10 of the discharge bin of the mixer, and specifically includes a valve plate 1, a connecting rod 2, an operating handle 3 and a limit fulcrum 4, and the bottom of the discharge bin is provided with a discharge port 10a, the limit The fulcrum 4 is set on one side of the discharge port 10a, the valve plate 1 is fixedly connected to one end of the connecting rod 2, and the surface of the valve plate 1 is opposite to the discharge port 10a, and the other end of the connecting rod 2 is connected to the operating handle 3 One end is hinged to form a hinge point 23, the hinge point 23 is in contact with the limit fulcrum 4, the middle part of the operating handle 3 is bent, the bending point 31 is hinged with the bracket 11 fixedly arranged at the bottom 10 of the discharge bin, and the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com