Flat Knitting Machine

A knitting machine and flat needle technology, which can be used in knitting, weft knitting, flat knitting machines with separate action needles, etc., can solve the problems of many assembly workers and complicated designs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

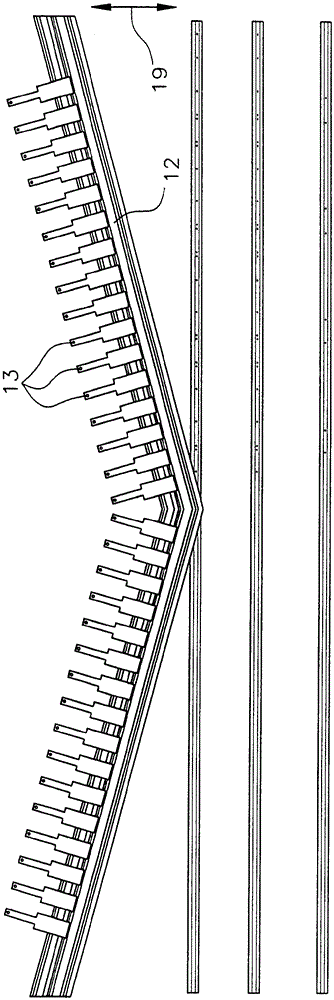

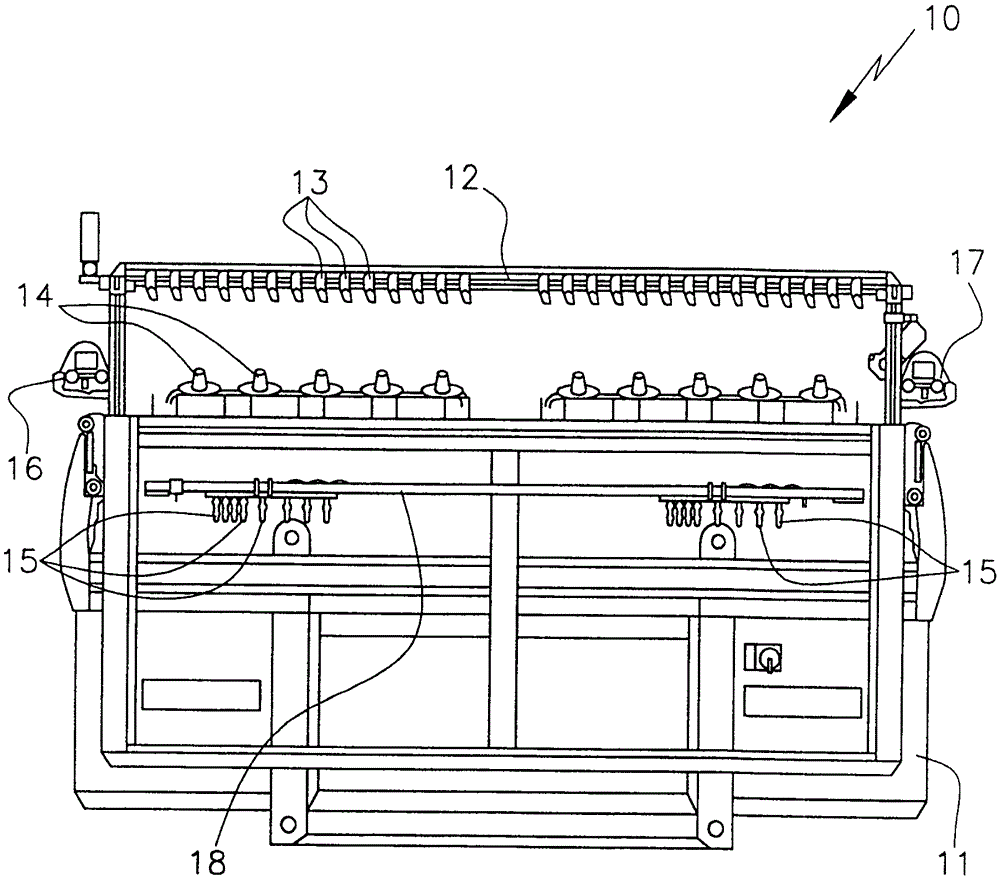

[0015] according to figure 1 The jersey knitting machine 10 has a support 12 arranged above a frame 11 for a plurality of yarn inspection devices 13 . These yarn inspection devices check the yarn drawn off from the bobbin 14 for knots or yarn breaks and are also usually provided with a yarn brake for generating the desired yarn tension. The yarn is supplied to one of the yarn guides 15 by the yarn inspection device 13 directly from above or via guide wires 16 , 17 arranged at the end face of the jersey knitting machine 10 . The thread guides 15 are arranged longitudinally displaceably in a rail system 18 having a plurality of parallel tracks, wherein at least two thread guides 15 are guided in each track. The yarn guides are moved along the tracks of the system 18 during the weaving process. Thus, the supplied yarns of the two yarn guides can cross. This is not a problem as long as the yarns do not touch here. The unraveling of the yarn transversely to the longitudinal dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com