Method for treating waste copper slag

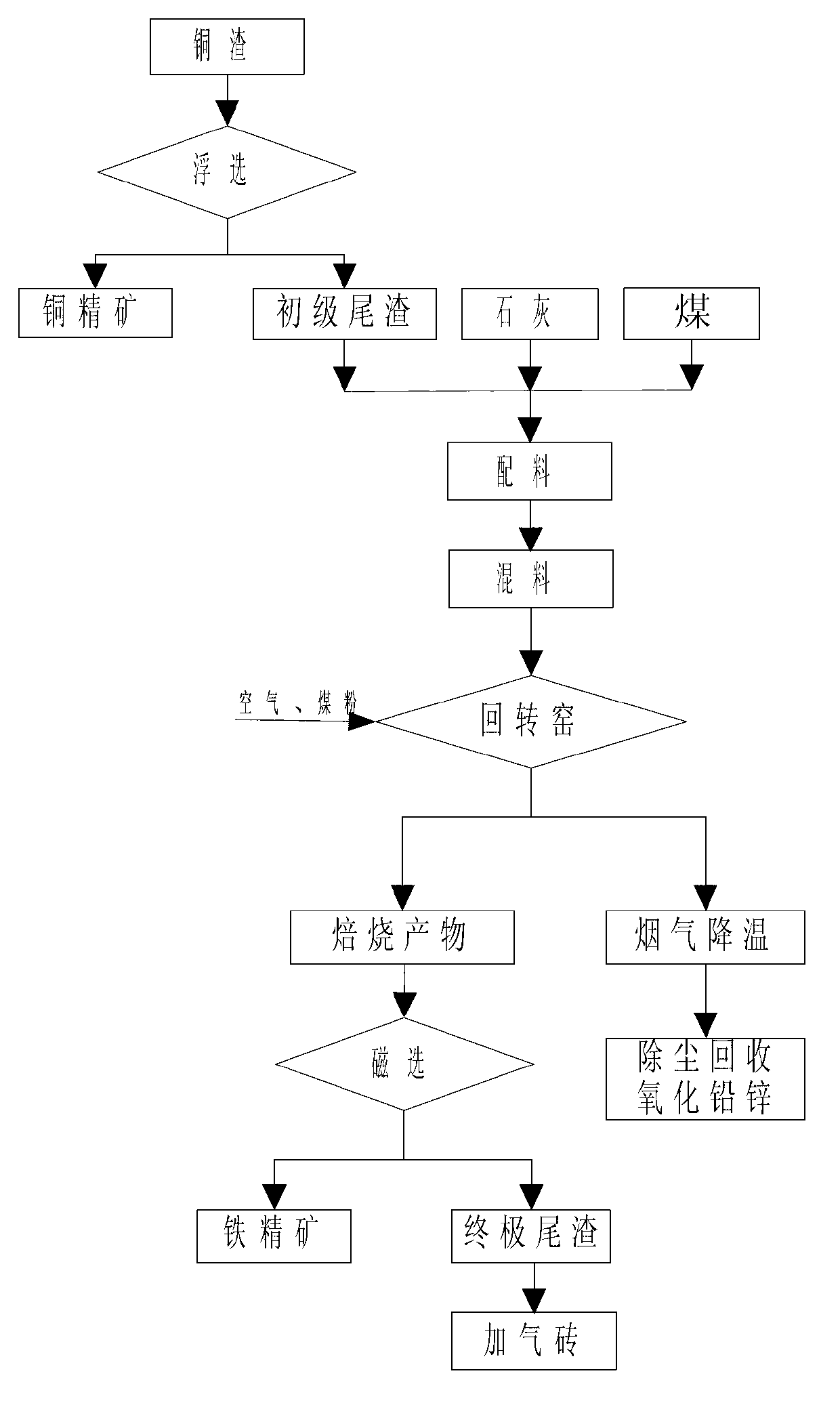

A treatment method, copper slag technology, applied in the field of comprehensive utilization of solid waste renewable resources, can solve problems such as ineffective, unrealized lead and zinc recycling, and low recycling efficiency, so as to reduce environmental pollution and realize effective recycling , the effect of reducing the negative impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment 1: The specific implementation content is to carry out the typical waste copper slag sample of a certain copper smelter, a total of 10kg (TFe=39.4%, Cu=0.62%, Zn=2.69%, Pb=0.63%) according to the process flow of the present invention Treatment, the treatment process is as follows: (1) Finely grind waste copper slag until the particle size is less than 74μm (200 mesh) accounting for more than 90%, and use flotation to produce copper concentrate. Specific process: roughing, three-stage beneficiation, and three-stage scavenging produce final copper concentrate (15% copper) and primary tailings; (2) primary tailings are mixed with 15% lime and 10% coal, and fully mixed , in a tubular resistance furnace to simulate the process conditions of the rotary kiln, heat preservation at 1000 ° C for 1 hour, and heat preservation at 1100 ° C for 1 hour; first reduction and then oxidation roasting. Use a bag dust collector to recover the dust, and finely grind the cooled oxi...

Embodiment 2

[0009] Embodiment 2. The specific implementation content is to carry out a total of 10kg (TFe=39.4%, Cu=0.62%, Zn=2.69%, Pb=0.63%) of a typical waste copper slag sample of a copper smelter according to the process flow of the present invention Treatment, the treatment process is: (1) finely grind waste copper slag until the particle size is less than 74μm (200 mesh) accounting for more than 95%, and use flotation to produce copper concentrate. The specific process: roughing, three-stage selection, three-stage sweeping The final copper concentrate (containing 12% copper) and primary tailings are produced through separation. (2) Add 20% lime and 8% coal to the primary tailings, mix well, and simulate the process conditions of the rotary kiln in a tubular electric resistance furnace, keep warm for 40 minutes at 1050°C, and keep warm for 50 minutes at 1150°C; Oxidation and roasting after reduction; dust is recovered with a bag filter; and the cooled oxidation and roasting product ...

Embodiment 3

[0010] Embodiment 3, the specific implementation content is that a typical waste copper slag sample of a copper smelter, a total of 1500kg (TFe=39.4%, Cu=0.62%, Zn=2.69%, Pb=0.63%) is processed according to the process of the present invention , the treatment process is as follows: (1) Finely grind waste copper slag until the particle size is less than 74μm (200 mesh) accounting for more than 90%, and use flotation to produce copper concentrate. Specific process: roughing, three-stage beneficiation, and three-stage sweeping to produce final copper concentrate (13% copper) and primary tailings. (2) The primary tailings are mixed with 12% lime and 6% coal, mixed thoroughly, and kept in a rotary kiln at 1020°C for 5 minutes, and at 1080°C for 50 minutes; first reduced and then oxidized and roasted. Use a bag filter to recover the dust, and finely grind the cooled oxidized and roasted product until the particle size is less than 74 μm (200 mesh) accounting for more than 90%, and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com