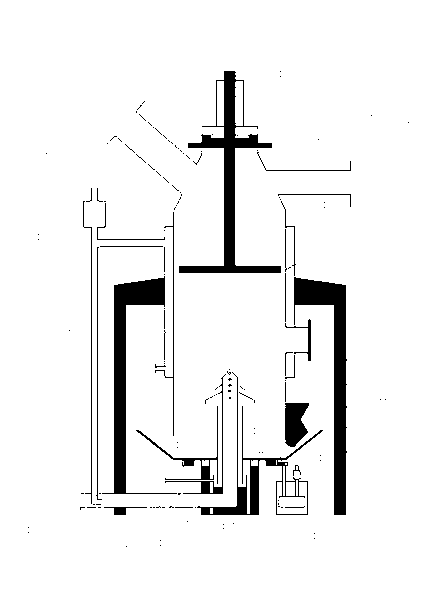

Household garbage gas generation furnace

A technology for gas generation and domestic waste, which is applied in the manufacture of combustible gas and the petroleum industry. It can solve the problems of lack of perfect classification system, low heat energy of domestic waste, and dependence on technical equipment, and achieve low cost, reduced dust emissions, and simple manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, charging: open the ignition port sealing door (12) of the domestic waste gas generator (1) furnace body supported by the furnace body brackets (34), (35) and fill the slag to the rotating slag tray (36 ), the height exceeds the liquid level of the water seal, fill in the match, close the ignition sealable door (12), connect the feeder with the garbage inlet flange (15) and push the domestic garbage into the domestic garbage gas generator (1 ), start the top sealing plate (8) to rotate by the motor (54) transmission shaft (52) on the upper part of the connecting ring (51) distributor seal assembly (50), and the distribution plate (53) distributes the garbage to the predetermined position and stops.

Embodiment 2

[0023] Embodiment 2, ignition: open the ignition port sealing door (12) and ignite the match with kindling, close the ignition port sealing door (12), open the induced draft fan to draw the gas out from the gas outlet (16), after the furnace heats up, the steam generator ( 19) Start to generate steam Start the supply fan from the steam outlet pipe (23) to the vertical pipe (24) to the steam mixing port (30).

Embodiment 3

[0024] Embodiment 3, gas generation: air enters the air supply port (27) through the air supply pipe flange (29) and mixes with steam at the steam mixing port (30) through the air supply pipe (28) and the air supply tower vertical pipe (31) for supply The cores (33) of the wind tower ventilation holes are distributed to the tower grate (32) and enter the hot carbon layer, and the furnace starts to generate gas according to the sequence of gas generation, and is drawn out by the induced draft fan and enters the burner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com