Preparation method of anti-hydrolysis organosilane surfactant

A technology of surfactant and organosilane, which is applied in the field of preparation of organosilane surfactant, can solve the problem of less product, and achieve the effects of low surface tension, favorable for industrial production and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

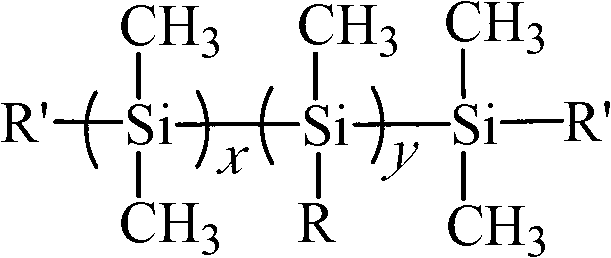

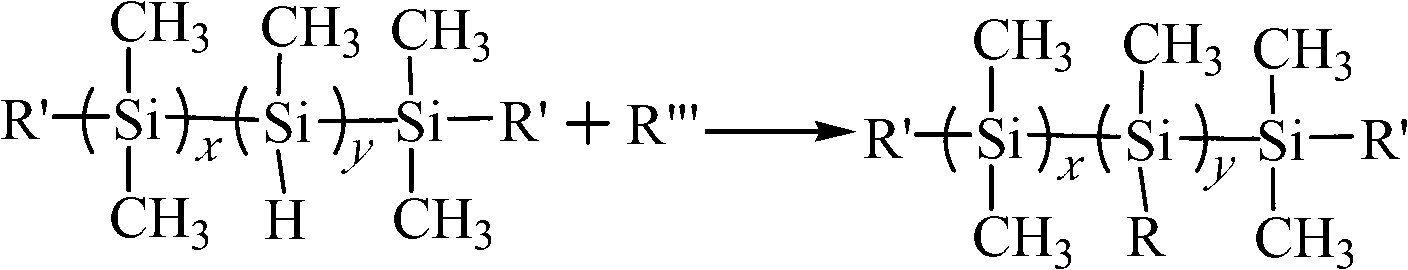

Method used

Image

Examples

Embodiment 1

[0031] Add 200mL xylene, a small amount of 15-crown ether, N 2 Under protection, add 11.2g of newly treated sodium block, start stirring, raise the temperature to 100°C to melt the sodium and stir quickly to make sodium sand, mix (CH 3 ) 3 SiCl and (CH 3 ) 2 A total of 47g of SiHCl raw material solution was added to the constant pressure dropping funnel. First, a small amount of raw material solution was added dropwise to initiate the reaction. The temperature was controlled at 90°C, and then the reaction solution was continued to be added dropwise. After 24 hours of reaction, it was cooled, suction filtered, and the filtrate was distilled and separated. The fraction boiling in the range 90-105°C was collected as a hydrosilane intermediate. Put the intermediate product in the flask, N 2 Turn on the stirrer under protection, add Karstedt Pt catalyst (calculated as Pt atoms) accounting for 0.001% mass fraction of the total reaction material, and activate at 90°C for 15 minut...

Embodiment 2

[0034] Add 200mL toluene to the flask, N 2 Under protection, add 14g of newly treated sodium block, start stirring, heat up to 100°C to melt the sodium and stir quickly to make sodium sand, mix (CH 3 ) 3 SiCl and CH 3 SiHCl 2 Add a total of 55g of the raw material solution into the constant pressure dropping funnel, first drop a small amount of the raw material solution to initiate the reaction, control the temperature at 90°C, then continue to drop the reaction liquid, react for 13 hours, cool down, filter with suction, and the filtrate is distilled out before 113°C Fractions and residual liquid are used as intermediate products containing hydrosilane. Put the intermediate product in the flask, N 2 Turn on the stirrer under protection, add Karstedt Pt catalyst (calculated as Pt atoms) accounting for 0.0015% mass fraction of the total reaction material, and activate at 90°C for 15 minutes; Polyoxyethylene ether (molecular weight 400) was reacted for 4h. Add activated cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com