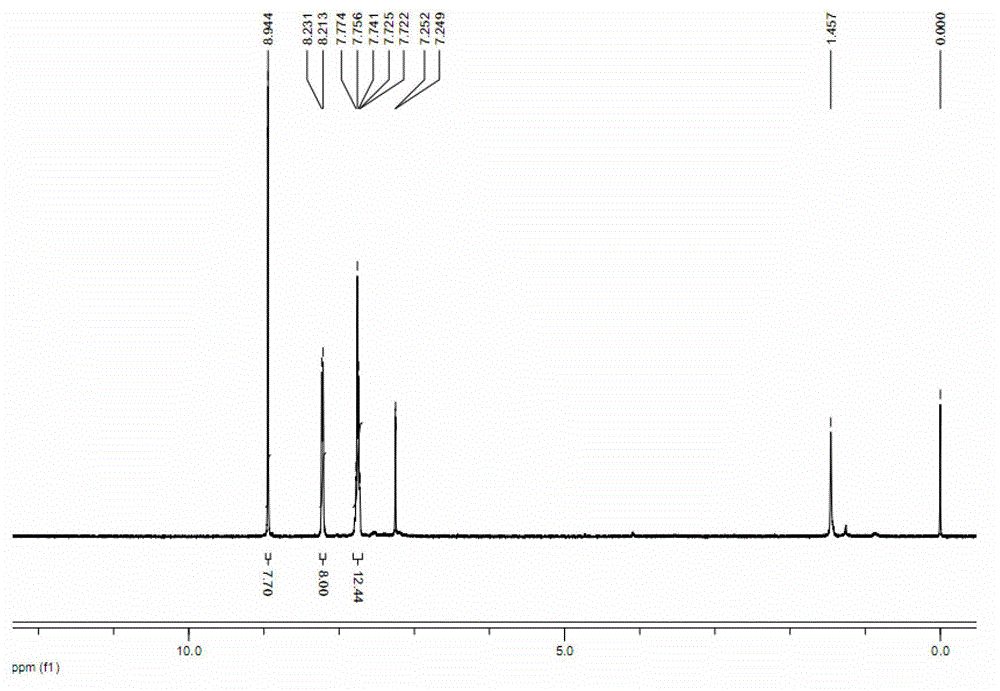

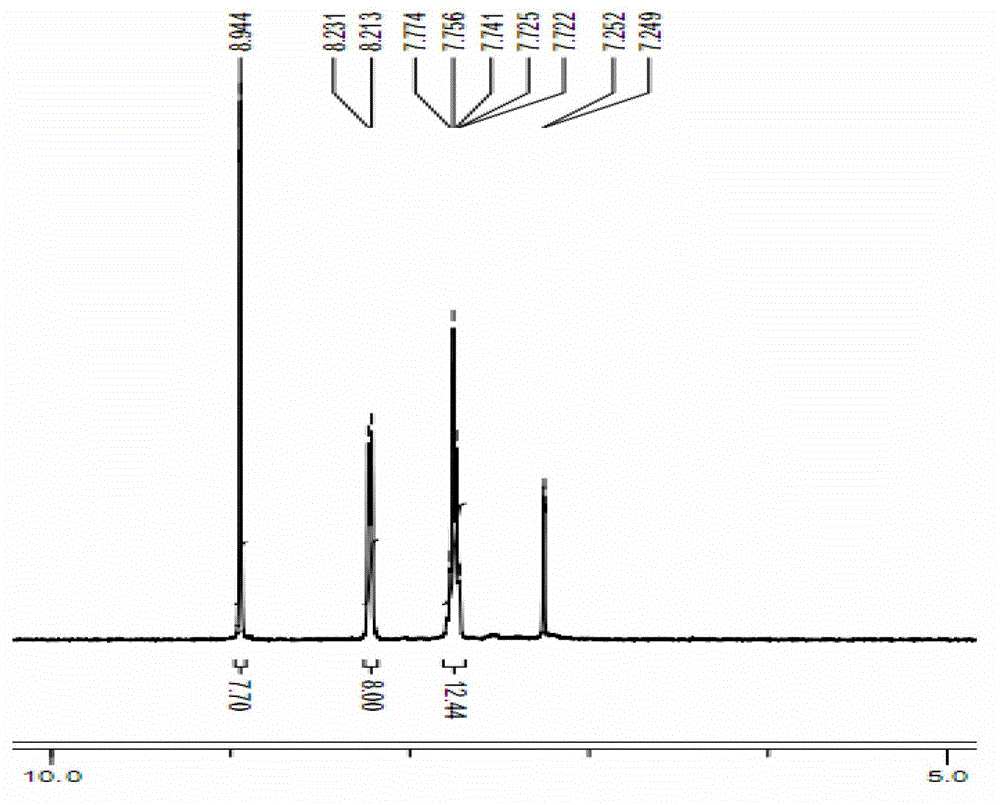

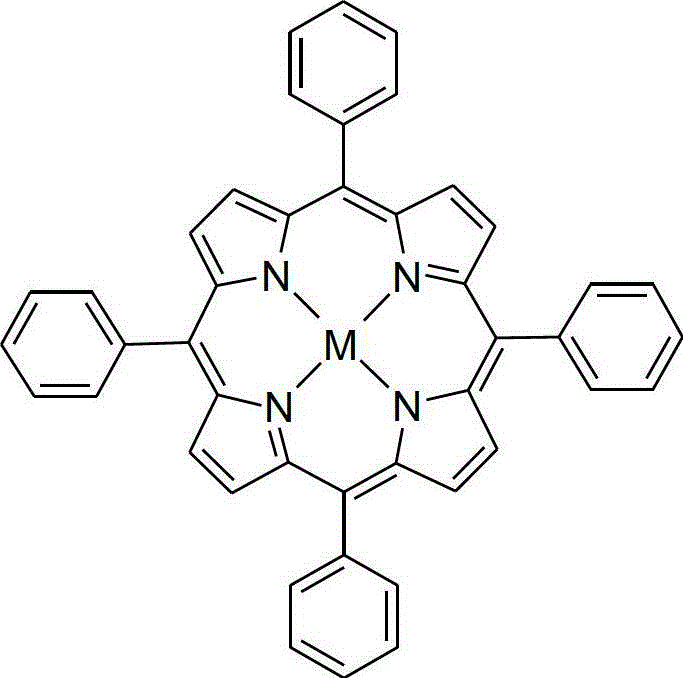

Method for synthesising tetraphenylporphyrin metal complex via one-step process

A technology of tetraphenylporphyrin and metal complexes, applied in the field of synthetic chemistry, can solve the problems of complex reaction process, long reaction time, difficult operation and the like, and achieves the effects of simple operation, low toxicity of raw materials and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Since pyrrole is easily oxidized when placed in the air for a long time, first reflux pyrrole at 115°C to obtain a colorless solution and store it in the dark. Measure 0.68ml of pyrrole and pour it into 3.5ml of propionic acid. Shake well and ready to use.

[0030] Step 2: Weigh 2.9g of zinc acetate, dissolve it in 35ml of DMF solution, stir to dissolve it completely, and pour it into a constant pressure dropping funnel for use.

[0031] Step 3: Add 35ml of propionic acid and 1ml of benzaldehyde into a 100ml three-necked flask, stir, and reflux at 140°C. After the temperature is stable, drop in 2.9g of zinc acetate dissolved in 35ml of DMF solution, then slowly add propionic acid solution dissolved in 0.65ml of pyrrole with a rubber dropper, and react for 90min after all the reactants have been added.

[0032] Step 4: After the reaction, cool down, pour the product into about 500ml of water, a large amount of black solid appears, filter with suction, and dry th...

Embodiment 2

[0035] Same as Example 1, but the zinc acetate in the second step changes copper acetate into, and the volume ratio of propionic acid and the DMF solution that is dissolved with copper acetate is 1:1.2, and every gram of copper acetate is dissolved in 15mlDMF solution, and reaction obtains Purple solid powder 0.22g, yield 15%.

Embodiment 3

[0037] Same as Example 1, but the zinc acetate in the second step changes nickel acetate into, and the volume ratio of propionic acid and the solution of the DMF that is dissolved with nickel acetate is 1:1.5, every gram of nickel acetate is dissolved in 16mlDMF solution, reaction Obtained 0.18 g of purple solid powder with a yield of 12%.

[0038] Note: The solubility of copper acetate and nickel acetate in DMF is not very high, and the metal salt should be ground into powder to facilitate dissolution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com