Seed crystal synthesis method for preparing ZSM-23 molecular sieve

A technology of ZSM-23 and molecular sieve, which is applied in the field of ZSM-23 molecular sieve preparation by seed crystal synthesis method, can solve the problems of a large amount of harmful gas, high crystallization temperature, and long crystallization time, and achieve low price, lower crystallization temperature, The effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Synthesis of ZSM-23 zeolite molecular sieve by seed crystal method

[0019] First, the 8.12gH 2 O and 0.092g of aluminum sulfate are mixed evenly, then 0.38g of NaOH is added to it, and then 3.32g of silica sol with a silica content of 30.5% is added under stirring, and the stirring is continued until the solution becomes uniform, and then 10% ZSM-23 molecular sieve is added to make Seed crystal (the amount of seed crystal is represented by input SiO 2 mass percent calculation). Add the reaction raw materials into a polytetrafluoroethylene stainless steel reaction kettle, perform dynamic crystallization at 160°C for 10 hours to complete the crystallization, filter the product with suction, and dry it to obtain the product. The proportioning of reaction raw material is as follows:

[0020] SiO 2 : 0.008319Al 2 o 3 :0.27 Na 2 O : 35H 2 O. The mass ratio of seed crystal to silicon source is 10%.

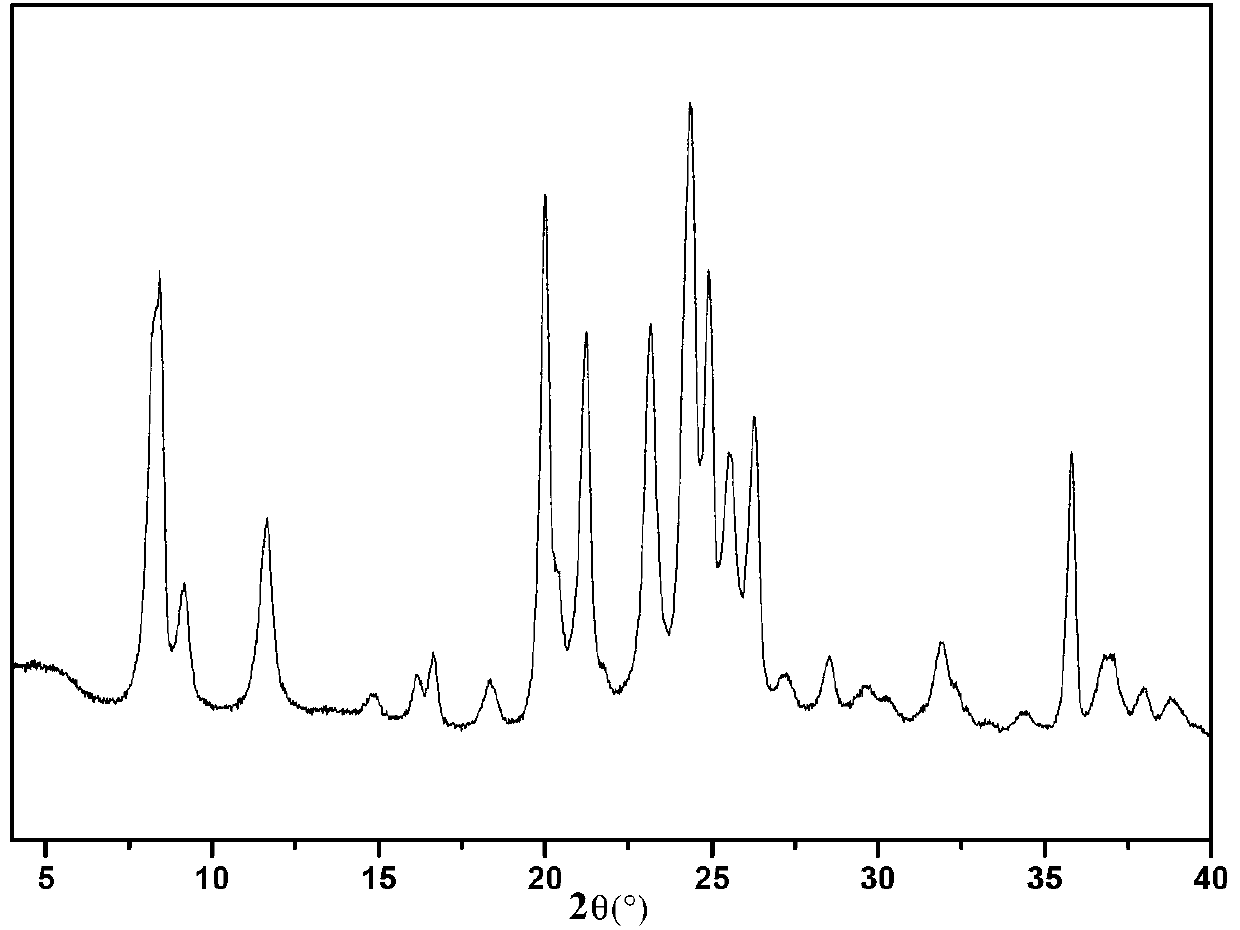

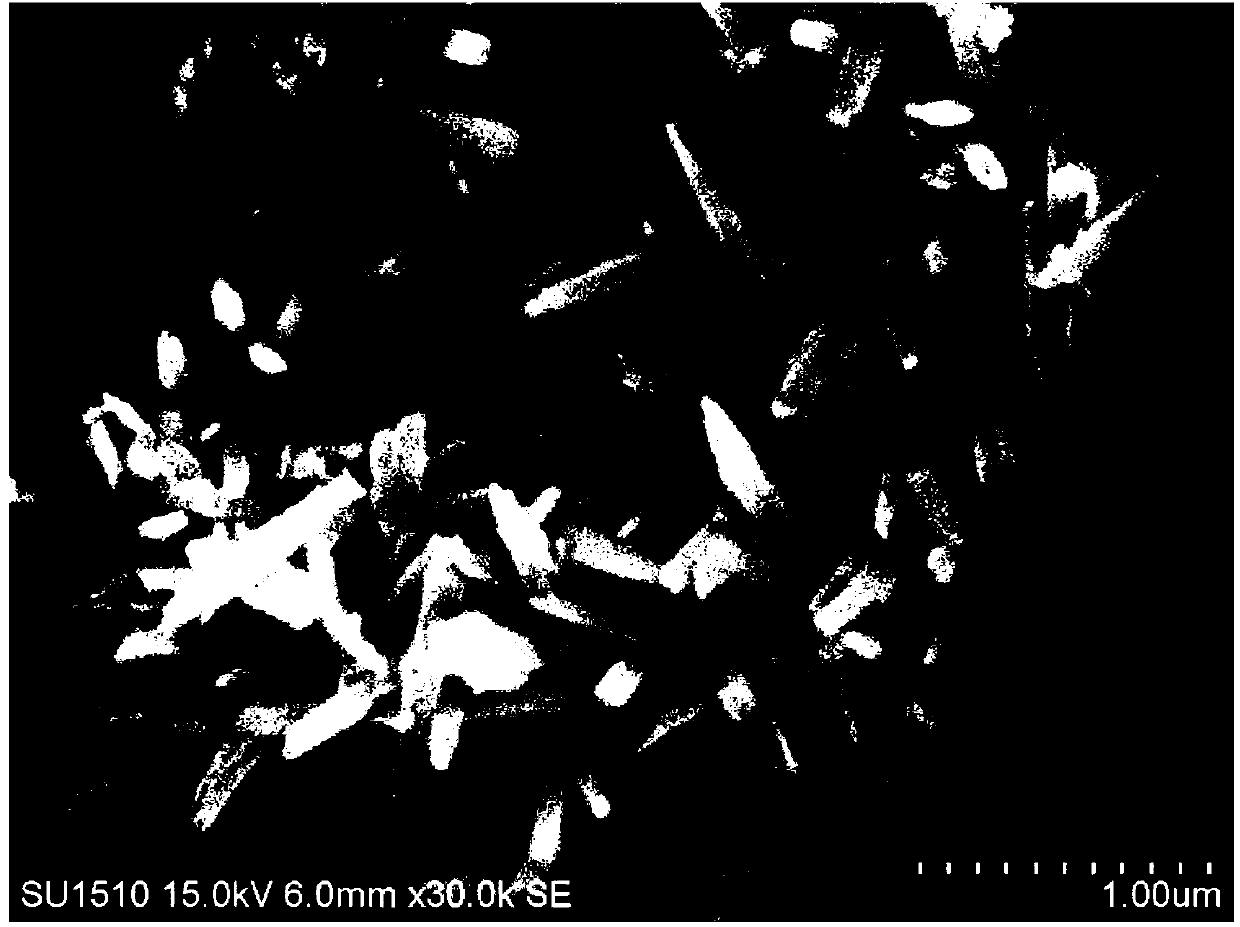

[0021] Its structure is ZSM-23 zeolite molecular s...

Embodiment 2

[0022] Embodiment 2: Secondary utilization of product prepared by seed crystal method

[0023] 8.12gH 2 O and 0.056g of aluminum sulfate are mixed evenly, then 0.35g of NaOH is added thereto, and then 3.32g of silica sol with a silicon dioxide content of 30.5% is added under stirring, and the stirring is continued until the solution becomes uniform, and then 10% of the compound synthesized in Example 1 is added. The ZSM-23 molecular sieve is used as the seed crystal (the amount of seed crystal is based on the input SiO 2 Calculated by mass percentage), after stirring evenly, the gel was added into a polytetrafluoroethylene stainless steel reactor, and dynamically crystallized in an oven at 160°C for 10 hours. The product was filtered with suction and dried.

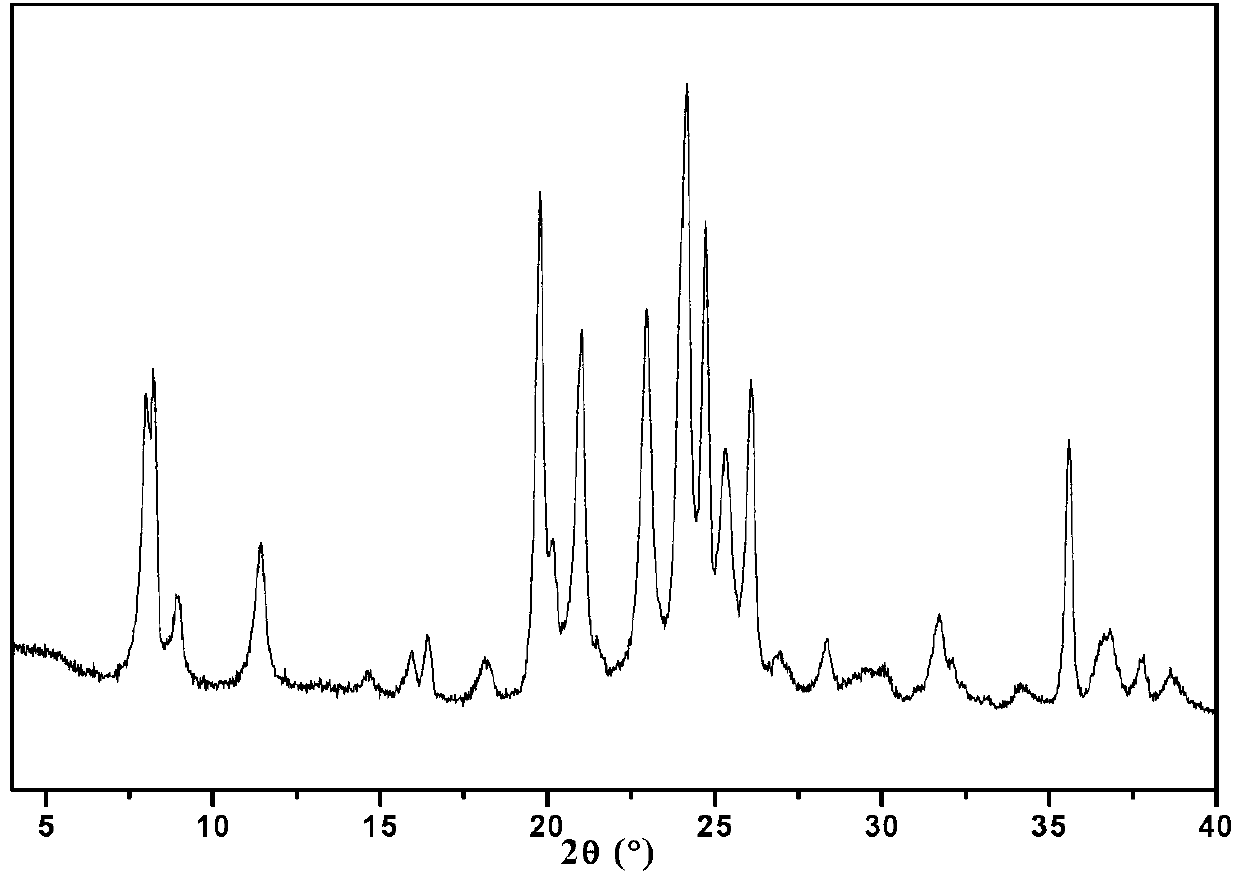

[0024] image 3 The XRD spectrum of the product synthesized by the reuse of the ZSM-23 zeolite molecular sieve prepared by the seed crystal method, it can be seen from the spectrum that the product has a typical ZSM-23...

Embodiment 3

[0026] Embodiment 3: Synthesis of ZSM-23 under relatively mild temperature

[0027] The preparation of the initial silica-alumina gel is the same as in Example 1. The preparation process of ZSM-23 zeolite molecular sieve is as follows: in the gel system prepared in embodiment 1, add 10% ZSM-23 molecular sieve as crystal seed (the amount of seed crystal is represented by input SiO 2 mass percentage), after stirring evenly, the gel was added into a polytetrafluoroethylene stainless steel reactor, and dynamically crystallized in an oven at 140°C for 50h. The product was filtered with suction and dried. The obtained product is analyzed by X-ray diffraction and its composition is ZSM-23 zeolite molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com