Tensile force detecting device for conveyer belt

A detection device and tension force technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as inability to make adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

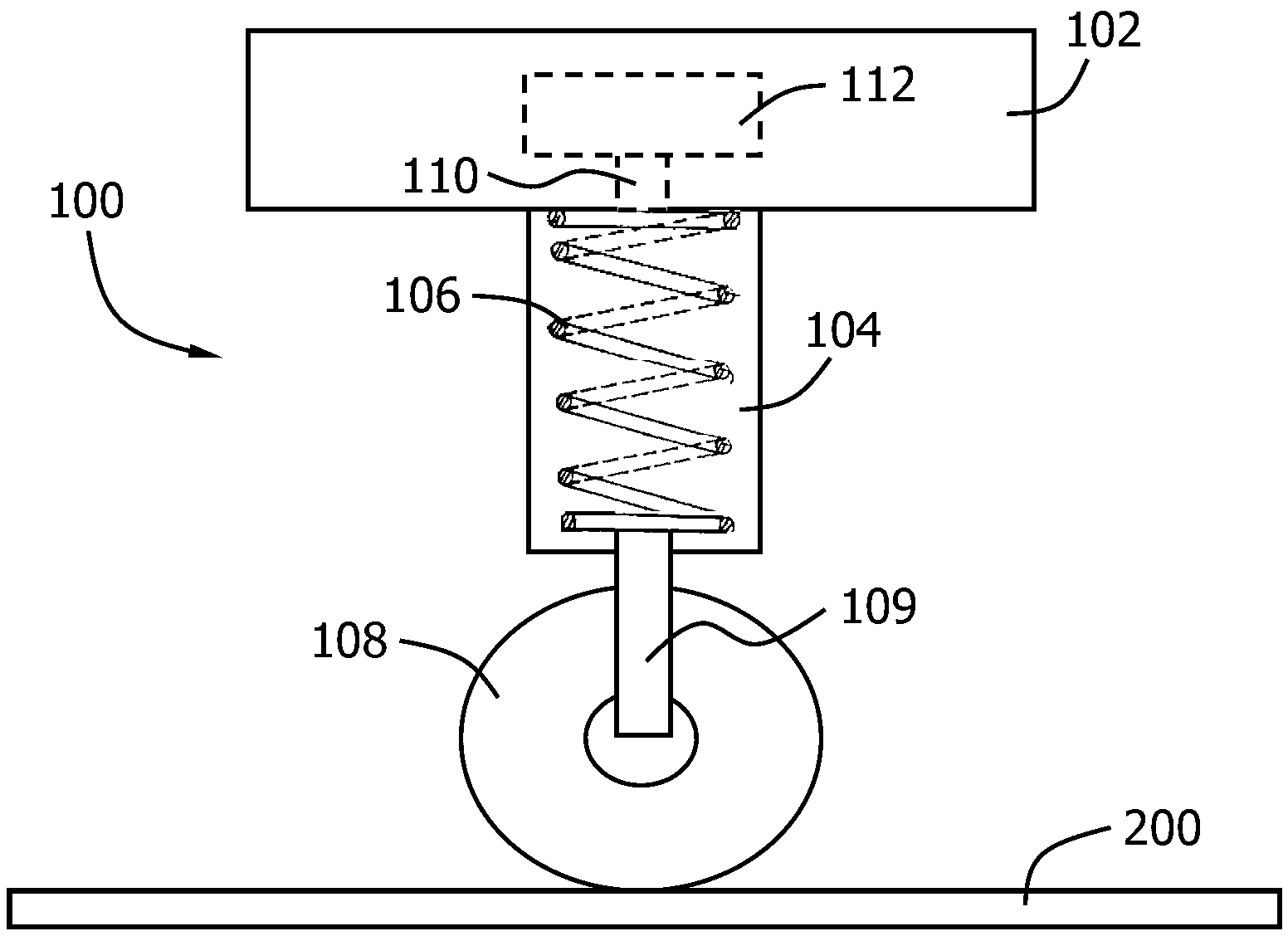

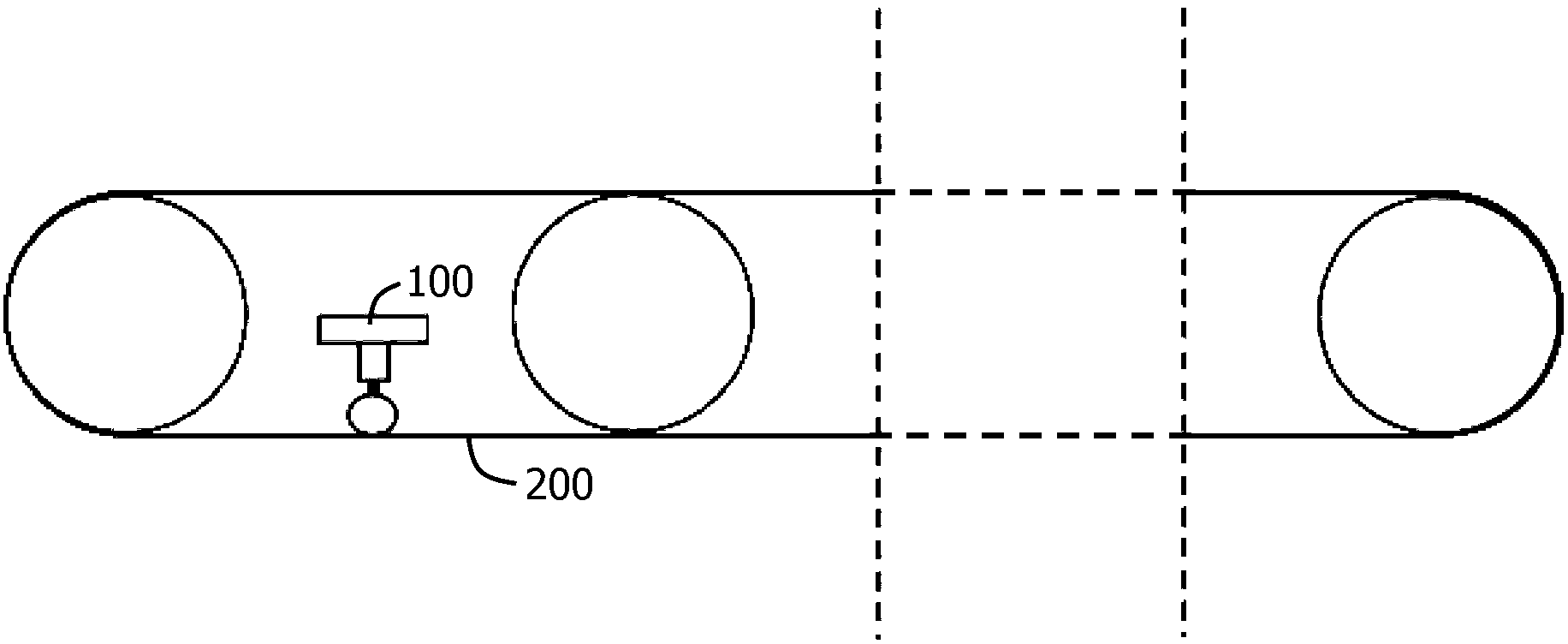

[0015] refer to figure 1 as shown, figure 1 A structural diagram of a tension detection device for a conveyor belt according to an embodiment of the present invention is disclosed. As shown in the figure, the conveyor belt tension detection device 100 includes a base 102 , a pipe 104 , a spring 106 , a pulley 108 , a connecting block 110 and a pressure sensor 112 . A base 102 is provided between the upper and lower sides of the conveyor belt, and the base 102 is hollow. The pipe 104 is connected to the base 102 , and the pipe 104 is arranged vertically. The pipe 104 is also hollow and the inside of the pipe 104 communicates with the inside of the base 102 . A spring 106 is placed in the tube 102 . The pulley 108 is mounted on the first end of the spring 106 through a pulley bracket 109 , and the first end is the lower end of the spring 106 . The rotating shaft of the pulley 106 is installed on the pulley bracket 109, and the pulley 108 bears against the inner surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com