Self-lubricating line guide rail structure

A self-lubricating and positioning technology, applied in the field of mold structure, can solve the problems of increasing labor costs and affecting the use time of molds, and achieve the effects of reducing labor costs, ensuring use time, and prolonging lubrication time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

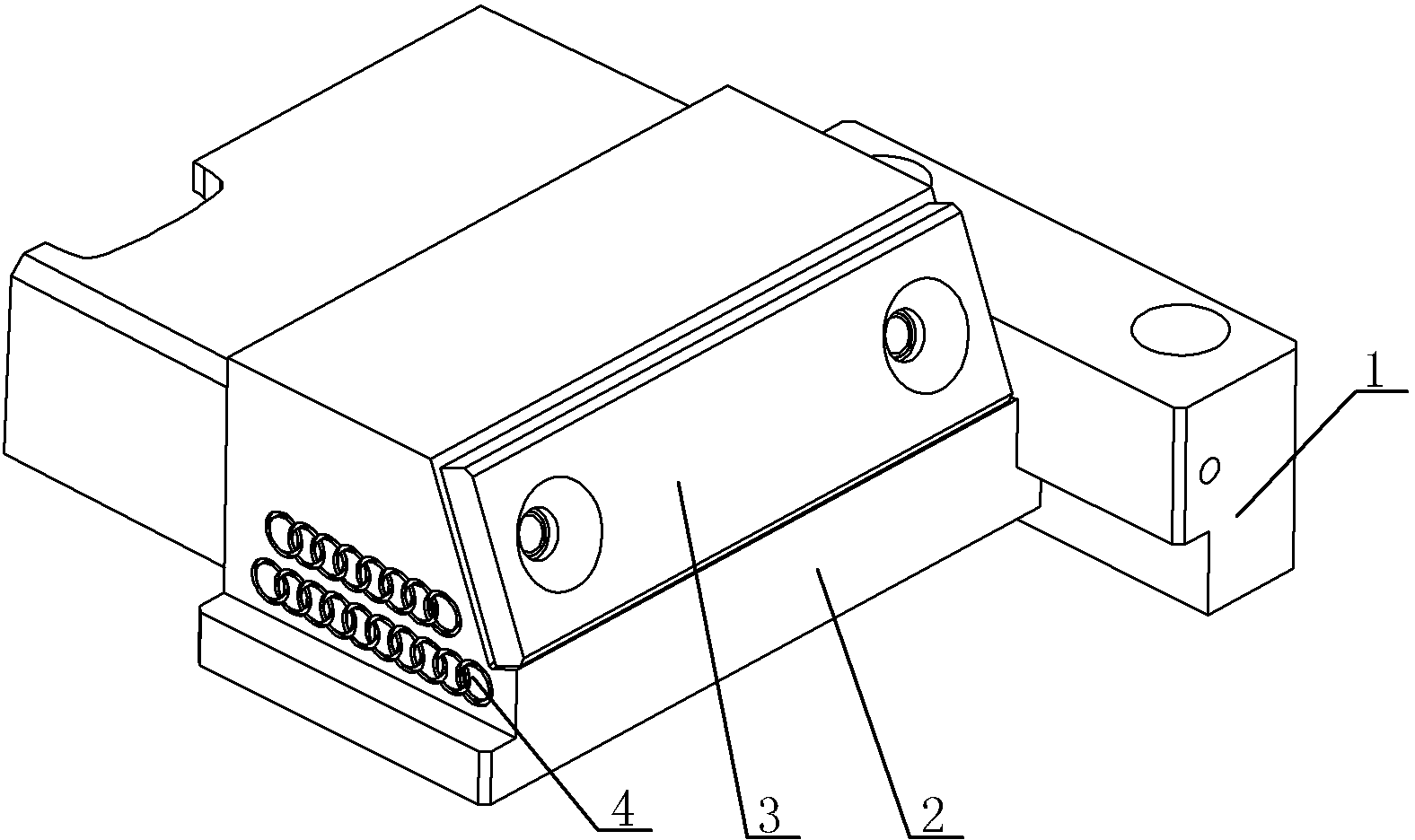

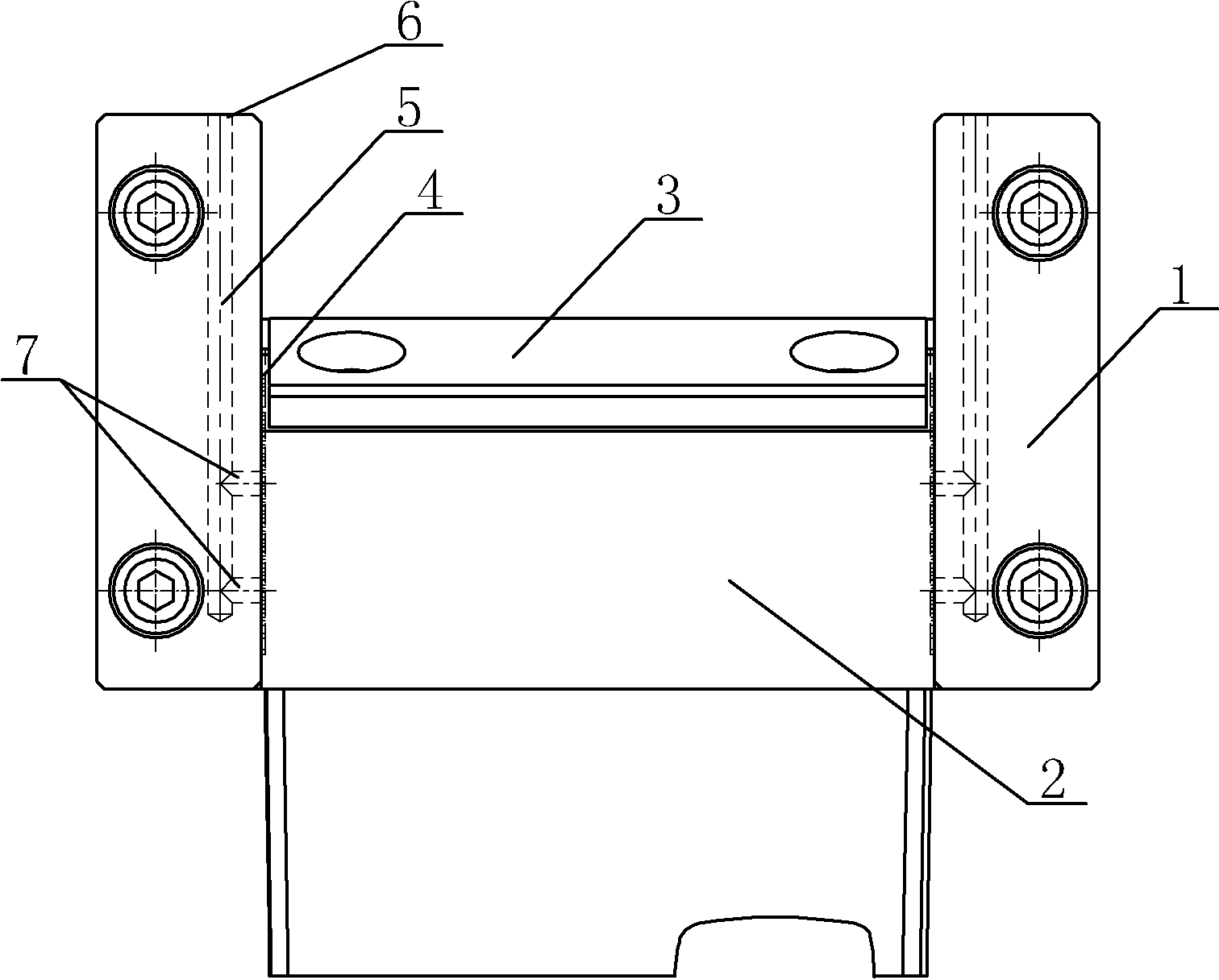

[0009] See figure 1 , figure 2 , which includes a row position linear guide 1, a row position seat 2, a row position insert 3, the row position insert 3 is fastened to one end of the row position seat 2, and both sides of the row position seat 2 are clamped on the row positions on both sides Linear guide 1, the area where the two sides of the row seat 2 are attached to the row linear guide 1 is provided with an annular oil groove 4, the annular oil groove 4 is arranged in a straight line along the row linear guide 1, and the inside of the row linear guide 1 is provided with a lubricating Lubricant oil passage 5, the oil inlet 6 of the lubricant oil passage 5 is located at the end face of the linear guide rail 1, the oil outlet 7 of the lubricant oil passage 5 is facing the annular oil groove 4, and the oil inlet 6 is installed with a check valve filler. The annular oil groove 4 arranged in a straight line covers the oil outlet 7 at a fixed position during the row movement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com