Bearing bush with surface microporous structure and processing method thereof

A surface micropore and microstructure technology, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of reducing bearing pad strength, unfavorable bearing pad bearing capacity, and increasing surrounding stress, so as to reduce abrasive wear and store Good oil effect and less stress concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The microporous structure and processing method of the bearing are described in detail below:

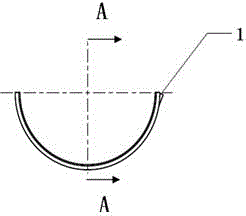

[0022] see figure 1 , Figure 1A , the bearing pad has a bearing pad body 1, the body 1 is composed of a metal pad back 3 and an antifriction alloy layer 4, wherein the antifriction alloy layer 4 is a friction layer between the bearing pad and the journal.

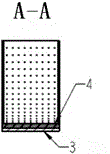

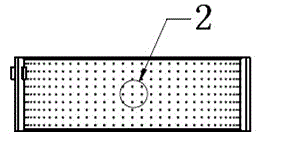

[0023] see figure 2 , image 3 , the inner surface of the antifriction alloy layer 4 is processed with regularly arranged micropores 2 . The specific processing method is:

[0024] First, a layer of resin is coated on the inner surface of the friction-reducing alloy layer 3 on the bearing body 1, and the resin is thin and easy to remove.

[0025] Then clamp it into the inner side of the semi-circular tooling, and use a pulse laser, preferably a Nd:YAG pulse laser, to process micro-holes in the bearing bush. Among them, the main parameters of Nd:YAG pulsed laser are: (a) Laser wavelength: 1064nm; (b) Crystal: Nd:YAG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com