Novel high-efficiency energy-saving planetary vacuum stirrer

A vacuum mixer, high-efficiency and energy-saving technology, applied in mixers, mixers, dissolving and other directions with rotating mixing devices, can solve the problems of poor mixing efficiency, low manufacturing cost, waste of man-hours and energy, etc., and achieve high mixing efficiency and mixing. Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

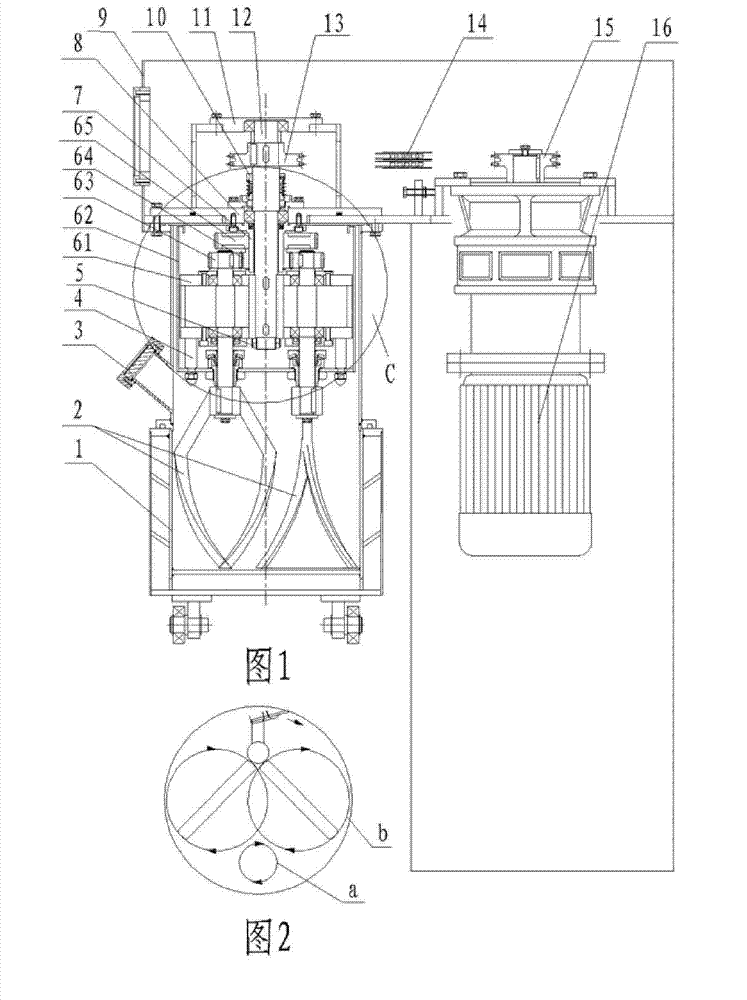

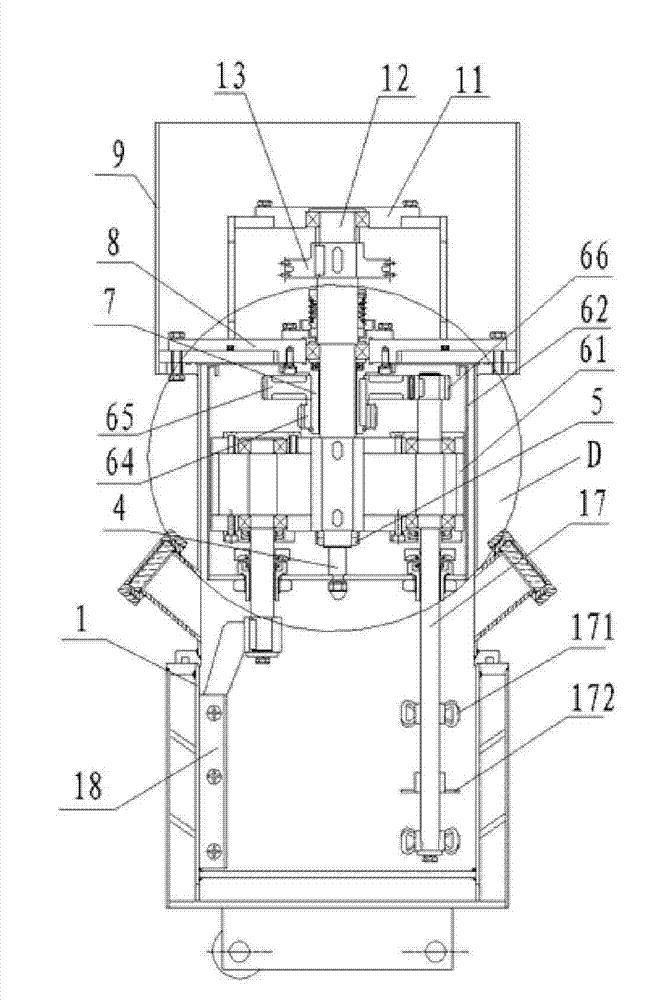

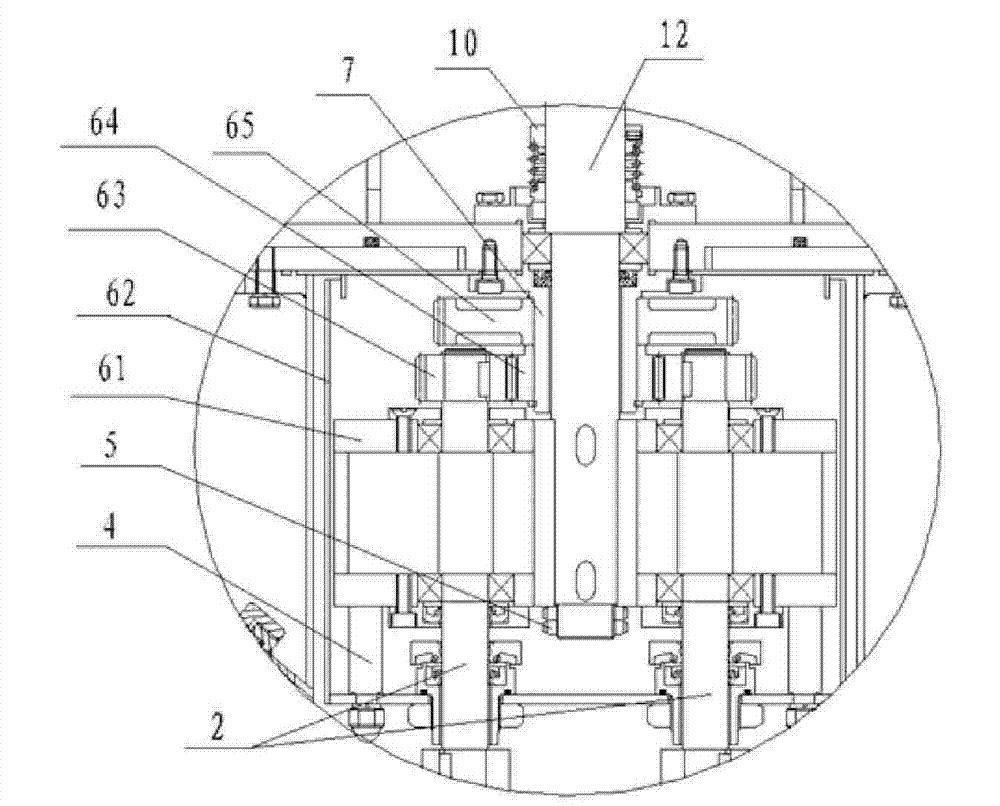

[0038]A new type of high-efficiency and energy-saving planetary vacuum mixer (see Figure 1-Figure 5 ), including the frame 9, the power unit 16, only one transmission shaft 12, a planetary gear train assembly, a mixing barrel 1, a group of high-speed dispersing assemblies 17, two groups of low-speed mixing assemblies 2 and a group of scraping wall assemblies 18, The transmission shaft 12 is connected to the power unit 16 through the sprockets 13 and 15 and the chain 14. The transmission shaft 12 is respectively installed on the frame through the upper bearing, the upper bearing seat 11 and the lower bearing and the lower bearing seat 7, and the lower bearing seat 7 has a cylinder. The segment empty sleeve is on the drive shaft 12, and a mechanical seal 10 is installed on the drive shaft above the lower bearing. The planetary gear train assembly is mainly composed of two sets of planetary gear trains, a planetary box 61 and a planetary shield 62. The planetary gear train and th...

Embodiment 2

[0040] A new type of high-efficiency and energy-saving planetary vacuum mixer, the basic structure of which is the same as the first embodiment, the difference is: the planetary gear I66 and the planetary gear II64 of the planetary gear train assembly have self-lubricating structures, that is, the planetary gear I66 and the planetary gear II64. An annular oil storage tank 601 is opened on the upper part, and an oil seepage hole 602 or a long oil seepage groove 603 is arranged in the middle or lower part of the oil storage tank (see Figure 6 to Figure 7-2 ), that is, its specific structure is:

[0041] The mixer includes a frame 9, a power unit 16, only one transmission shaft 12, a planetary gear train assembly, a mixing barrel 1, a set of high-speed dispersing assemblies 17, two sets of low-speed stirring assemblies 2 and a set of scraping wall assemblies 18, The transmission shaft 12 is connected to the power unit 16 through the sprockets 13 and 15 and the chain 14. The tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com