Microwave and vacuum frying integrating device for food processing, and efficient frying method

A microwave vacuum frying and conditioning food technology, applied in oil/fat roasting and other directions, can solve the problems of uneven temperature rise and uneven product quality, and achieve the effects of low cost, improved brittleness and accurate temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

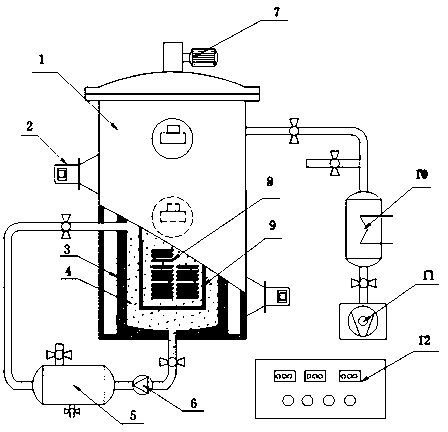

Image

Examples

Embodiment 1

[0041] Embodiment 1 Microwave vacuum frying method of peas

[0042] Pick out 250 g of peas with full grains, uniform size, no mildew, no damage, no moths, diseases, spots, rust spots, yellow skin, and shriveled beans at a mass concentration of 2% Na 2 CO 3 Soak in the solution for 30 minutes, then blanched at 95°C for 2 minutes, then cooled quickly with running water, and the drained peas were completely frozen at -20°C. After the frozen peas are loaded into the hanging basket 9, after the oil pump 6 is turned on, the palm oil in the oil storage tank is pumped into the microwave vacuum frying container 3, the microwave generator 2 is turned on, and the microwave power is adjusted to 1500 W, so that the oil temperature Rapidly rise to 100°C, turn off the oil pump 6. Turn on the water ring vacuum pump 11 to make the vacuum degree reach 0.098MPa. The frying end point can be observed through the observation window on the microwave heating chamber 1. The frying end point is when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com