Flame-proof type frequency conversion integrated permanent-magnet synchronous motor

A technology of permanent magnet synchronous motor and frequency conversion control cabinet, which is applied in the direction of synchronous machine parts, electric components, magnetic circuit rotating parts, etc., which can solve the problems of low power density and efficiency, high price, and reduced motor volume, etc., to achieve Good recovery and damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in detail below in conjunction with accompanying drawing:

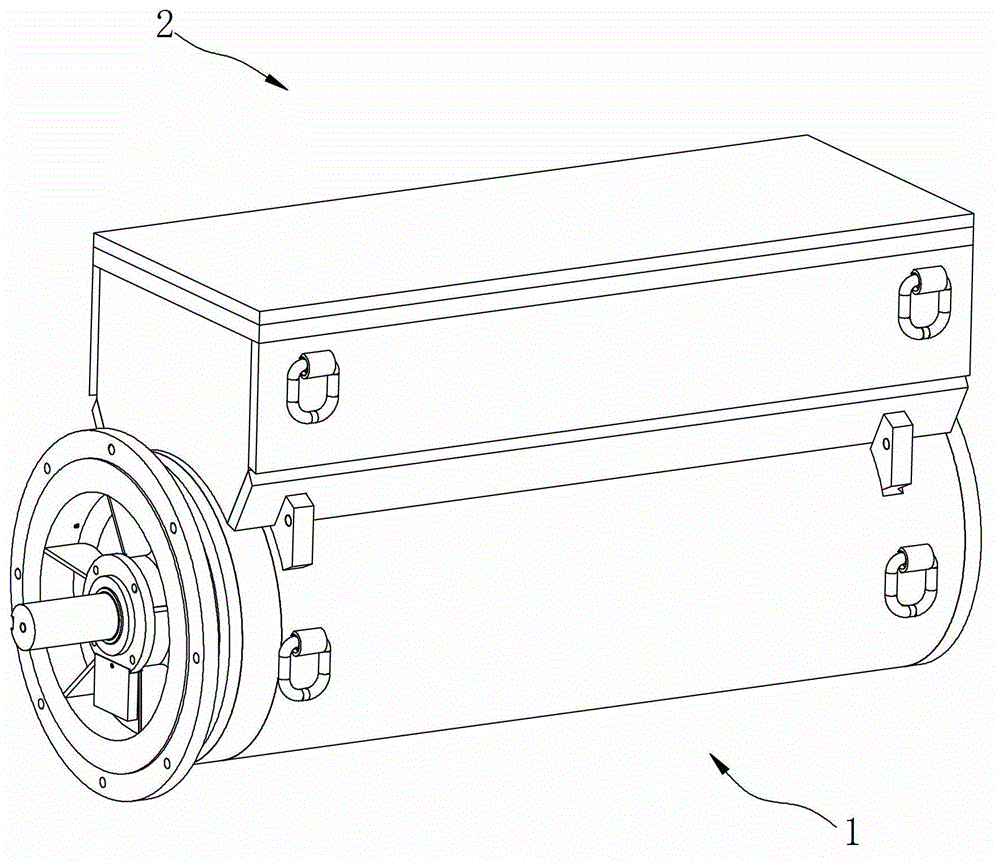

[0047] combine Figure 1 to Figure 9 , a permanent magnet synchronous motor, including a base 1 and a frequency conversion control cabinet 2, the frequency conversion control cabinet 2 is welded on the base 1.

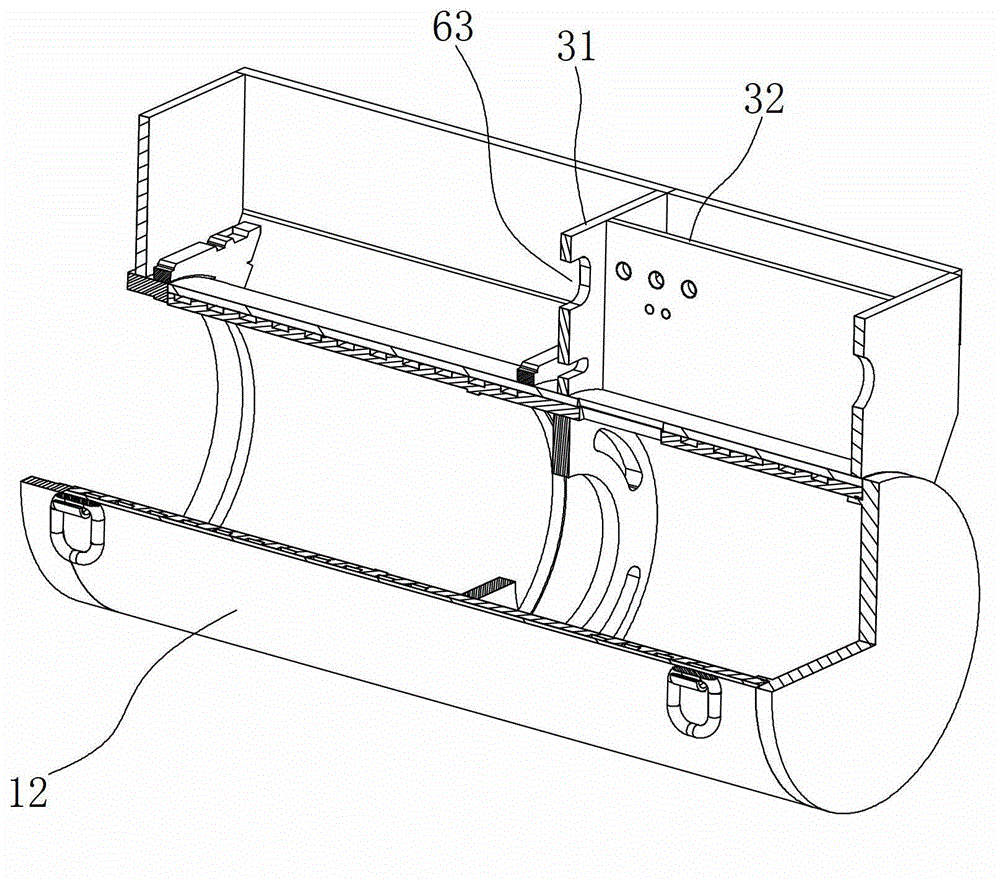

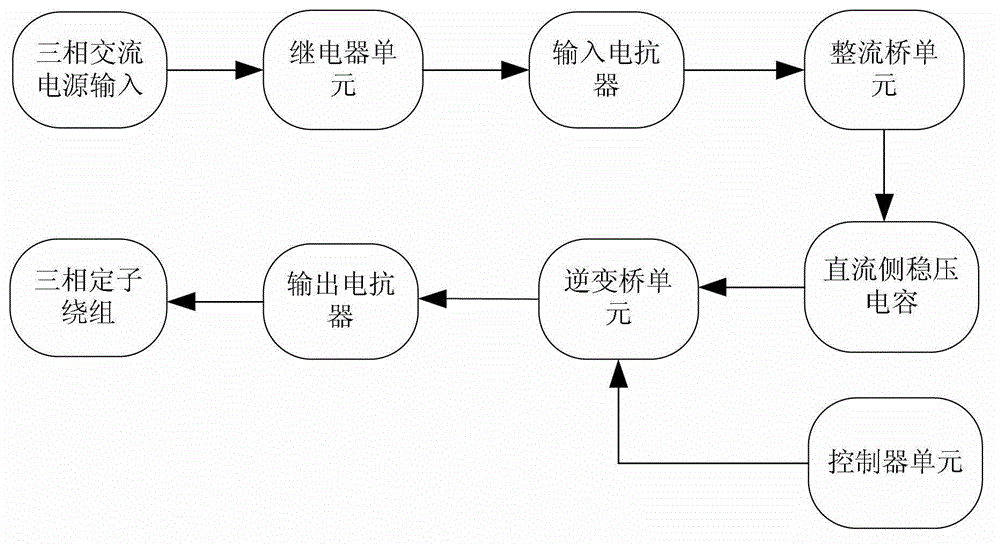

[0048] The inside of the frequency conversion control cabinet 2 is divided into a first cavity 21, a second cavity 22 and a third cavity 23 by partitions 31, 32, and the first cavity 21 is provided with a rectifier bridge unit 41, a DC The side voltage stabilizing capacitor 42 and the inverter bridge unit 43 are integrated on the water cooling plate 44, and the water cooling plate 44 is provided with a U-shaped array of water cooling tubes inside. The second cavity 22 is provided with a controller unit 45 and a contactor unit 46 , and the third cavity 23 is provided with input power terminals and main and auxiliary power supply terminals.

[0049]The machine base 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com