Nonaqueous electrolyte solution for lithium iron phosphate lithium-ion battery

A lithium-ion battery, non-aqueous electrolyte technology, applied in the field of chemical materials, can solve the problems of increasing the internal resistance of the battery, affecting the performance of the battery, reducing the cycle efficiency of the battery, etc., and achieving the effect of increasing the cycle life and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

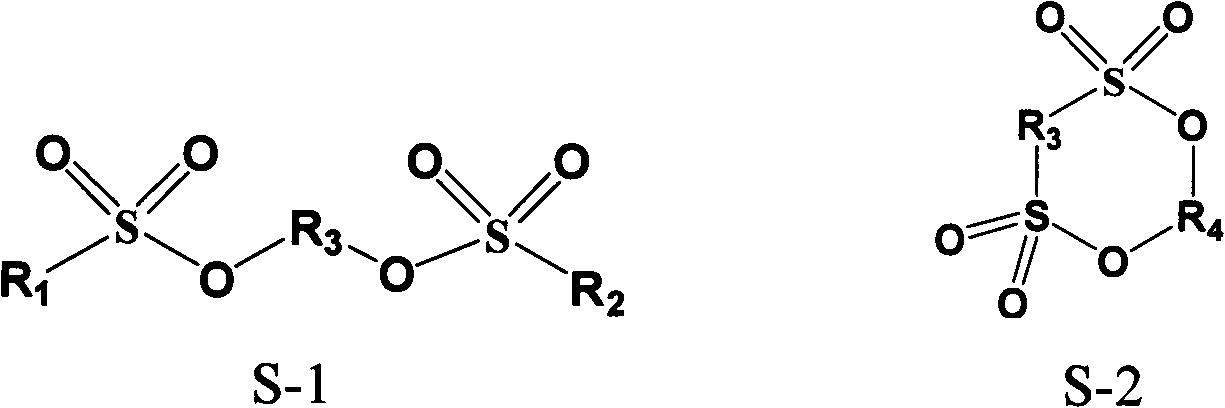

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be further described below in conjunction with specific embodiments.

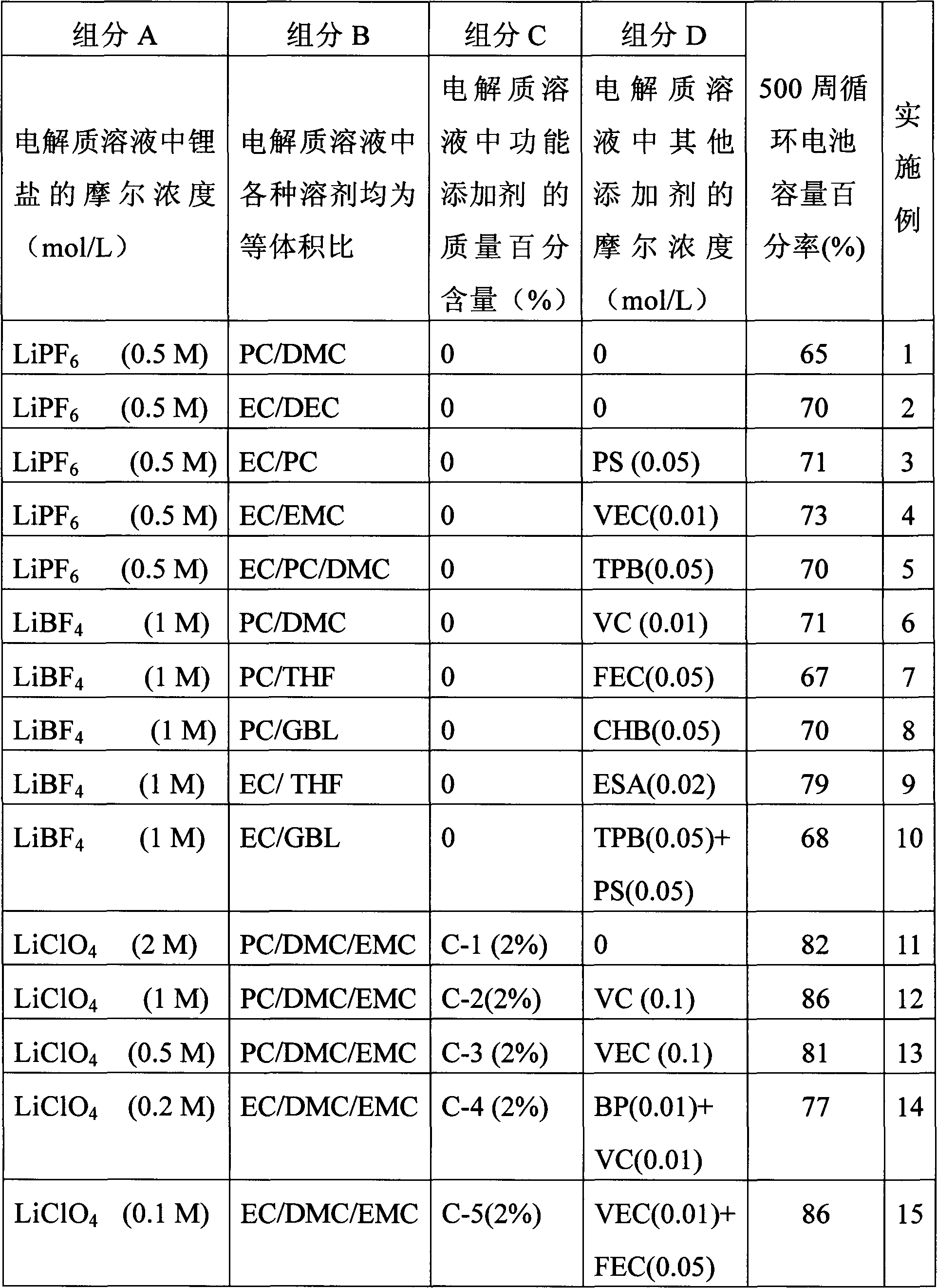

[0023] The present invention exemplifies the composition of 1 to 74 kinds of non-aqueous electrolyte solutions and the test data of the capacity retention rate of the battery using each electrolyte solution in the form of a table, see Table 1 below for details. Among them, the first 10 examples are comparative examples without adding component C, the 1st to 50th examples are 500 cycle battery capacity percentages at room temperature, and the 51st to 74th examples are 500 cycles at 60°C. Cycle cycle battery capacity percentage.

[0024] Table 1 Components of non-aqueous electrolyte solution and percentage of battery capacity

[0025]

[0026]

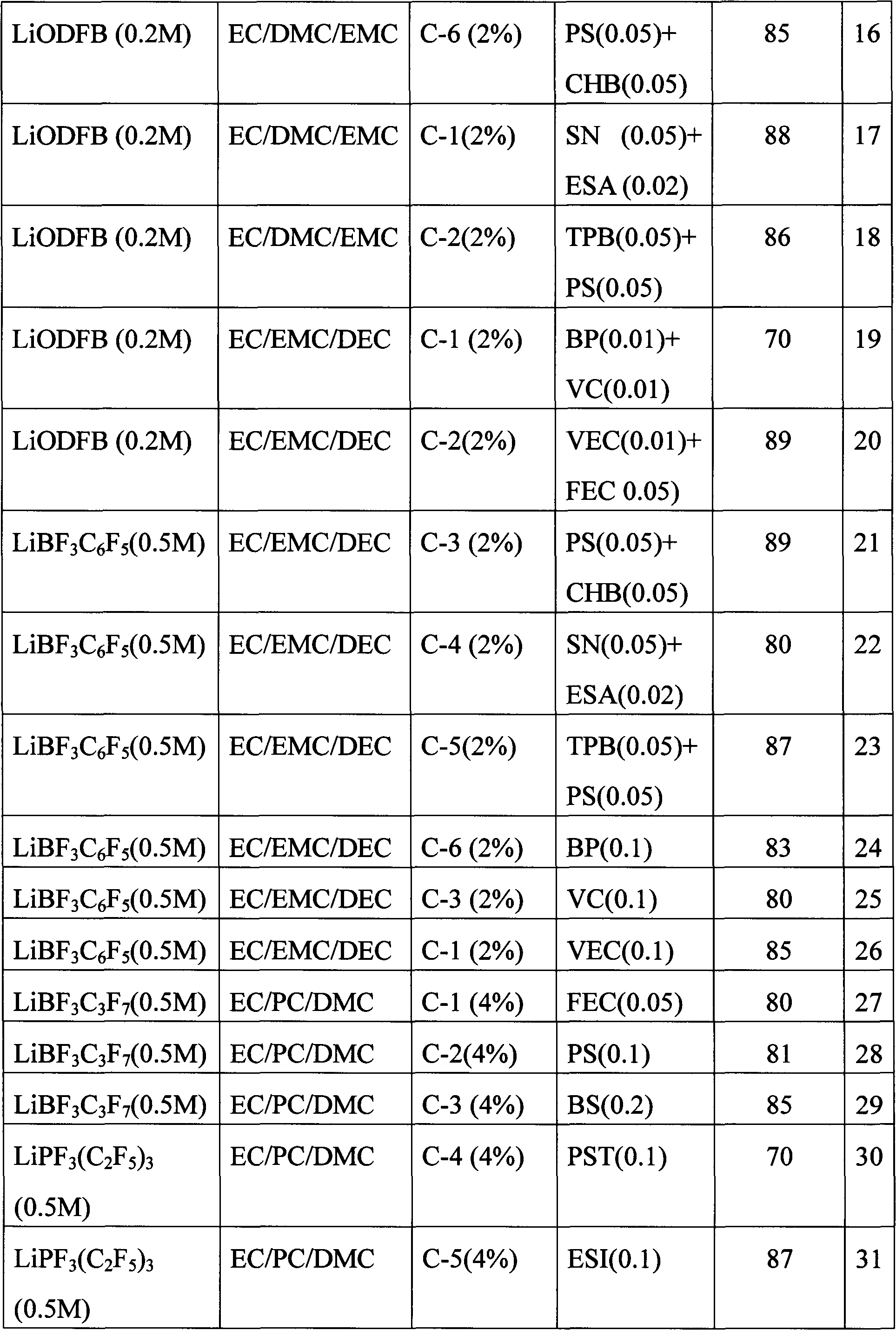

[0027]

[0028]

[0029]

[0030]

[0031] As can be seen from the above examples, the non-aqueous electrolyte solution added with functional additives can reduce the reduced iron ions on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com