Radio frequency identification (RFID) ultrathin metal-resisting electronic tag based on folded dipole

An electronic label and folded vibrator technology, applied to record carriers, instruments, computer parts, etc. used in machines, can solve the problems of inability to bend, thick size, and low sensitivity of metal surfaces, and achieve high flexibility, convenient production, Solve complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

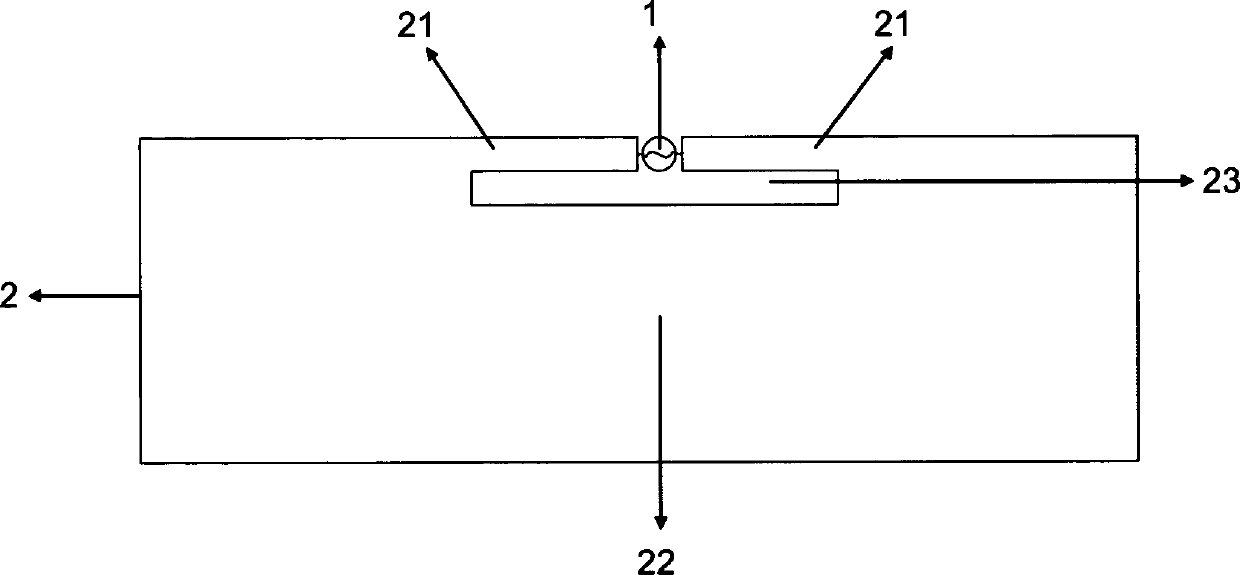

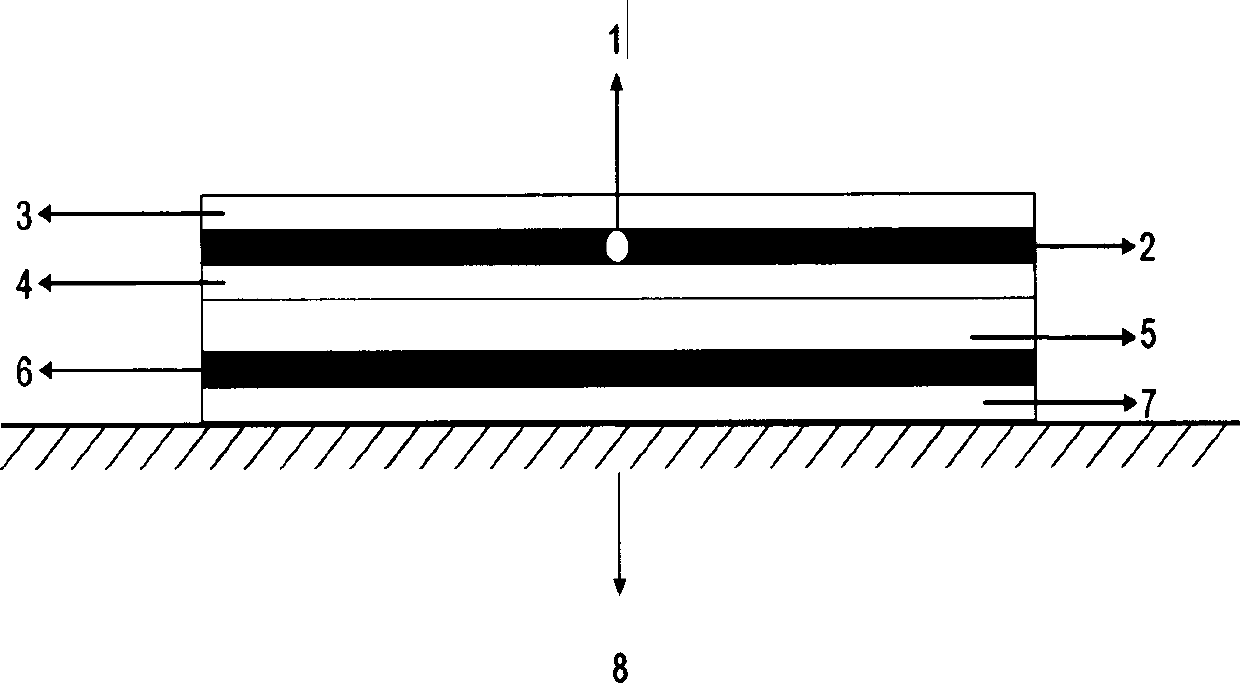

[0031] figure 1 figure 2 Shown is an ultra-thin plane anti-metal electronic tag based on a folded vibrator according to an embodiment of the present invention, wherein, figure 1 It is a schematic plan view of the electronic tag in Embodiment 1 of the present invention; figure 2 It is a schematic cross-sectional structure diagram of the electronic tag in Embodiment 1 of the present invention. Such as figure 1 and figure 2 As shown, the ultra-thin anti-metal electronic tag includes an ultra-high frequency RFID chip 1 and a radiator 2, the radiator 2 includes a feed loop gap 23, and the ultra-high frequency RFID chip 1 has a thin vibrator on one side of the feed loop gap 23 On the arm 21, there is a gap in the middle of the thin vibrator arm 21 for placing the UHF RFID chip 1. The thin vibrator arm 21 is electrically or capacitively connected to the UHF RFID chip 1. The feed loop gap 23 can be rectangular, Oval, trapezoidal or deformed structures, and the slot length of t...

Embodiment 2

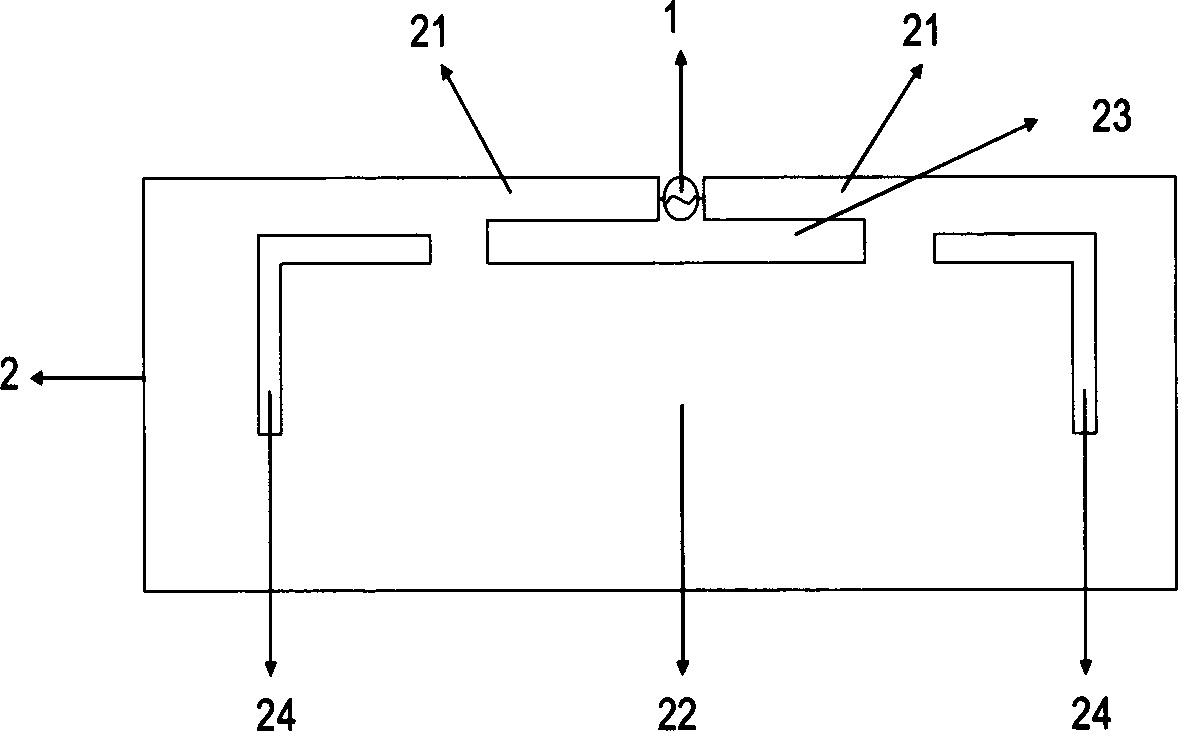

[0037] See image 3 , image 3 is a schematic diagram of the planar structure of the electronic tag in Embodiment 2 of the present invention; the structure of the electronic tag in this embodiment is the same as figure 1 Compared with the electronic tag in the shown embodiment 1, its general structure is similar, the cross-sectional structure schematic diagram in the embodiment 2 and the figure 2 Exactly the same, except that image 3 A frequency fine-tuning slit 24 is added to the radiator 2. Changing the size of the frequency fine-tuning slit 24 can play a role in adjusting the frequency, but it is not the main factor determining the performance of the label.

Embodiment 3

[0039] See Figure 4 , Figure 4 It is a schematic plan view of the electronic tag in Embodiment 3 of the present invention. The structure of the electronic tag in this embodiment is the same as image 3 Compared with the electronic tag in the shown embodiment 2, the radiator 2 increases the second feeding loop gap 231, and by changing the size of the second feeding loop gap 231, the electronic tag can be operated in two frequency ranges. Work to achieve the purpose of expanding the bandwidth of electronic tags. The schematic diagram of the cross-sectional structure in embodiment 3 and such as figure 2 The schematic diagrams of the cross-sectional structures in the shown embodiment 1 and embodiment 2 are completely the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com