Afterheat utilization device of sintering machine

A sintering machine, waste heat technology, applied in waste heat treatment, lighting and heating equipment, furnace components, etc., can solve the problem of flue gas temperature and flow fluctuations, the difficulty of continuous normal production of waste heat boilers, and the low operation rate of steam turbine generator sets. To the stability requirements and other issues, to achieve the effect of slowing down the load fluctuation, avoiding frequent start of the generator set, and stabilizing the operation of the generator set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

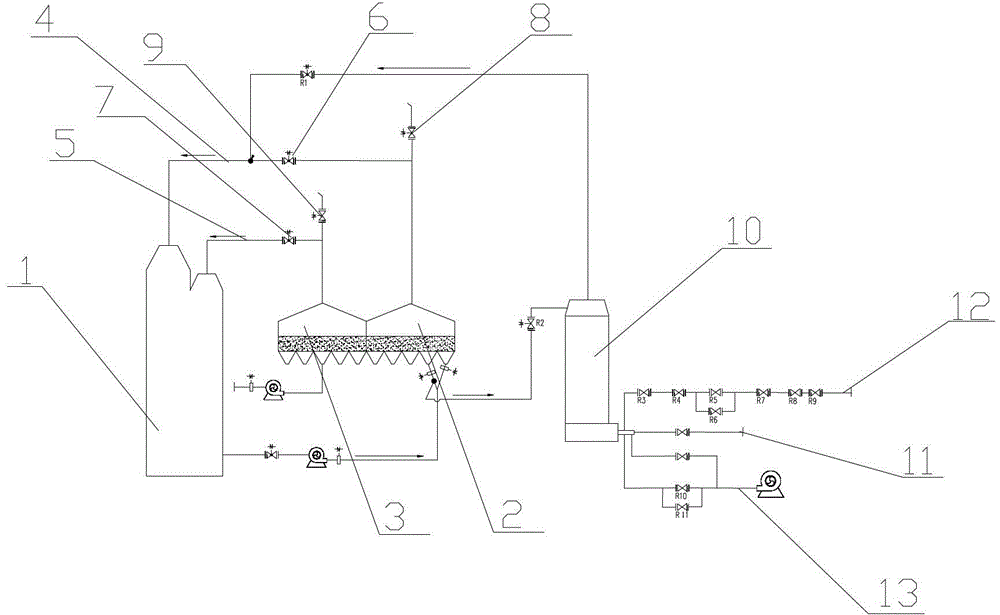

[0020] The structure of this embodiment is as figure 1 As shown, a sintering machine waste heat utilization device includes a waste heat boiler 1 and two sets of annular coolers 2 and 3 connected to the waste heat boiler, which are respectively connected to the waste heat boiler 1 through a high-temperature flue gas pipeline 4 and a medium-temperature flue gas pipeline 5. A high-temperature flue gas regulating valve 6 is installed on the section from the annular cooler 2 to the waste heat boiler of the flue gas pipeline 4, and a medium-temperature flue gas regulating valve 7 is installed on the section from the annular cooler 3 to the waste heat boiler of the medium-temperature flue gas pipeline 5. The end of the flue gas pipeline is provided with a high-temperature flue gas pipeline relief valve 8 and a medium-temperature flue gas pipeline relief valve 9 respectively, and a compensation hot blast stove 10 is also installed between the waste heat boiler 1 and the annular cooler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com