Method for preparing chitosan-like efficient flocculant

A technology of flocculant and chitosan, which is applied in the field of preparation of high-efficiency chitosan flocculants, can solve the problems of high production cost, achieve convenient application, good effect, and be conducive to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

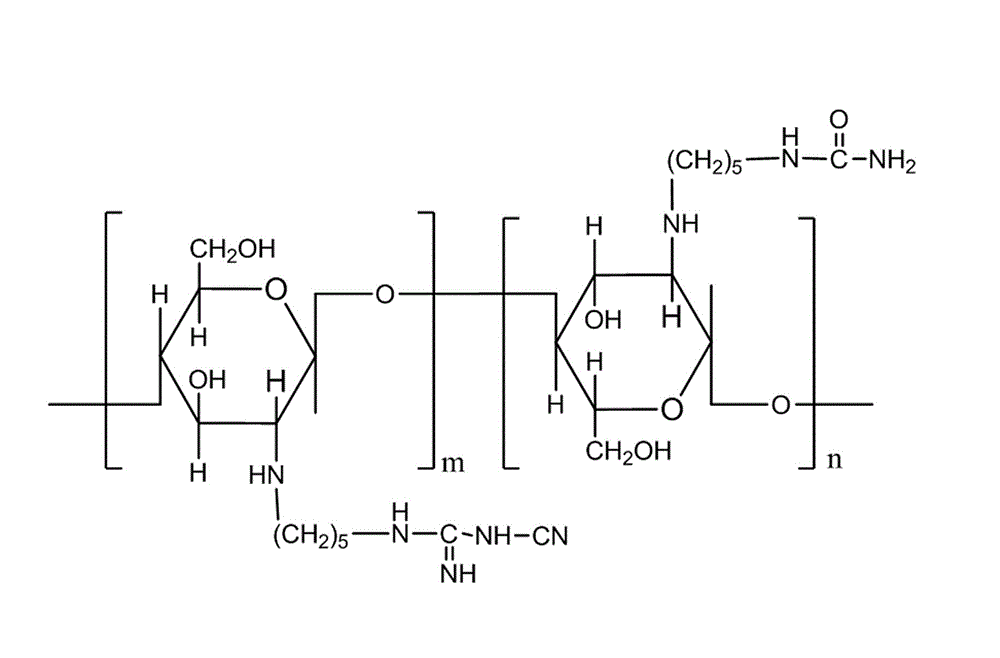

Image

Examples

Embodiment 1

[0020] The preparation method of chitosan high-efficiency flocculant, carries out following steps successively:

[0021] 1) Chitosan pretreatment: dissolve chitosan in acetic acid solution with pH=5, stir evenly, add alkali to pH=9 to precipitate chitosan, and suction filter for later use;

[0022] 2) Preparation of high-efficiency flocculant: Take 1 part of chitosan, 3 parts of glutaraldehyde crosslinking agent, 1 part of urea, and 1.5 parts of aluminum sulfate in a four-necked flask, stir, and pre-react in a water bath at 60 ° C for 1 Hour; Then add 2.1 parts of dicyandiamide, 0.9 part of urea, continue to react for 2 hours, obtain urea-chitosan-dicyandiamide composite flocculant;

[0023] 3) Purification of the product: After the reaction is completed, the product is precipitated with acetone, filtered with suction, and then washed with ethanol, filtered with suction and dried in an oven at 90°C for later use.

[0024] The flocculant obtained in Example 1 above was used to...

Embodiment 2

[0028] The preparation method of chitosan high-efficiency flocculant, carries out following steps successively:

[0029] 1) Pretreatment of carboxymethyl chitosan: dissolve carboxymethyl chitosan in acetic acid solution with pH=5, stir evenly, add alkali to pH=9 to precipitate carboxymethyl chitosan, and filter with suction.

[0030] 2) Preparation of high-efficiency flocculant: Take 2 parts of carboxymethyl chitosan, 5 parts of glyoxal crosslinking agent, 1 part of urea, and 3 parts of aluminum sulfate in a four-necked flask, stir, and pre- React for 0.5 hours. Then add 2.4 parts of dicyandiamide and 0.6 part of urea, and continue to react for 4 hours to obtain urea-chitosan-dicyandiamide composite flocculant;

[0031] 3) Purification of the product: After the reaction is completed, the product is precipitated with acetone, filtered with suction, and then washed with ethanol, filtered with suction and dried in an oven at 90°C for later use.

[0032] The flocculant obtained ...

Embodiment 3

[0036] The preparation method of chitosan high-efficiency flocculant, carries out following steps successively:

[0037] 1) Pretreatment of 0-hydroxyethyl chitosan: dissolve 0-hydroxyethyl chitosan in acetic acid solution with pH=5, stir evenly, add alkali to pH=9 to make O-hydroxyethyl chitosan The sugar precipitated out and was filtered by suction.

[0038] 2) Preparation of high-efficiency flocculant: Take 1.5 parts of the above-mentioned O-hydroxyethyl chitosan, 4 parts of glutaraldehyde crosslinking agent, 1 part of urea, and 2 parts of aluminum sulfate in a four-necked flask, stir, and place in a 70°C water bath Medium pre-reaction for 0.8 hours. Then add 2.4 parts of dicyandiamide and 0.6 part of urea, and continue to react for 3 hours to obtain urea-chitosan-dicyandiamide composite flocculant;

[0039] 3) Purification of the product: After the reaction is completed, the product is precipitated with acetone, filtered with suction, and then washed with ethanol, filtere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com