Polyisobutylene succinimide quaternary ammonium salt emulsifier and preparation method thereof

A technology of polyisobutylene succinimide and polyisobutylene succinic anhydride, which is used in offensive equipment, non-explosive/non-thermal agent components, explosives, etc., can solve the problems of unsatisfactory stability of emulsifiers and achieve stable Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

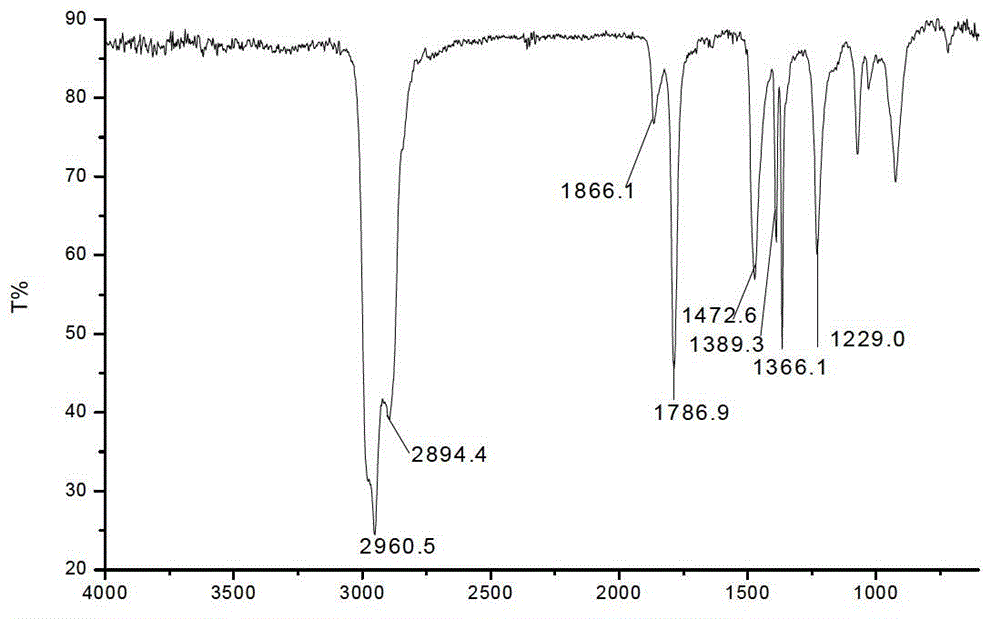

Embodiment 1

[0045] 82.4g (0.08mol) of polyisobutylene succinic anhydride (Mn=1030g / mol) with a saponification value of 108.86mg / gKOH, 33.0g of base oil were put into the reactor, and N,N-dimethyl-1,3-propane Add 8.0g (0.078mol) of diamine to the dropping funnel, stir, heat up to 40°C, add N,N-dimethyl-1,3-propanediamine dropwise, after the dropwise addition, continue to react for 1.0h, Raise the temperature to about 130~150°C, and under the vacuum degree of 0.08MPa, when the acid value is basically unchanged, the reaction is ended to obtain polyisobutylene succinimide, and 5.7g of base oil is added to make the base oil account for the weight of the mass. 30% of.

[0046]Put 79.5g (0.05mol) of the polyisobutylene succinimide product prepared above into the reactor, add 8.5g (0.055mol) of diethyl sulfate into the dropping funnel, stir, raise the temperature to about 80°C, and add sulfuric acid dropwise After the diethyl ester is added dropwise, continue to react until the amine value is su...

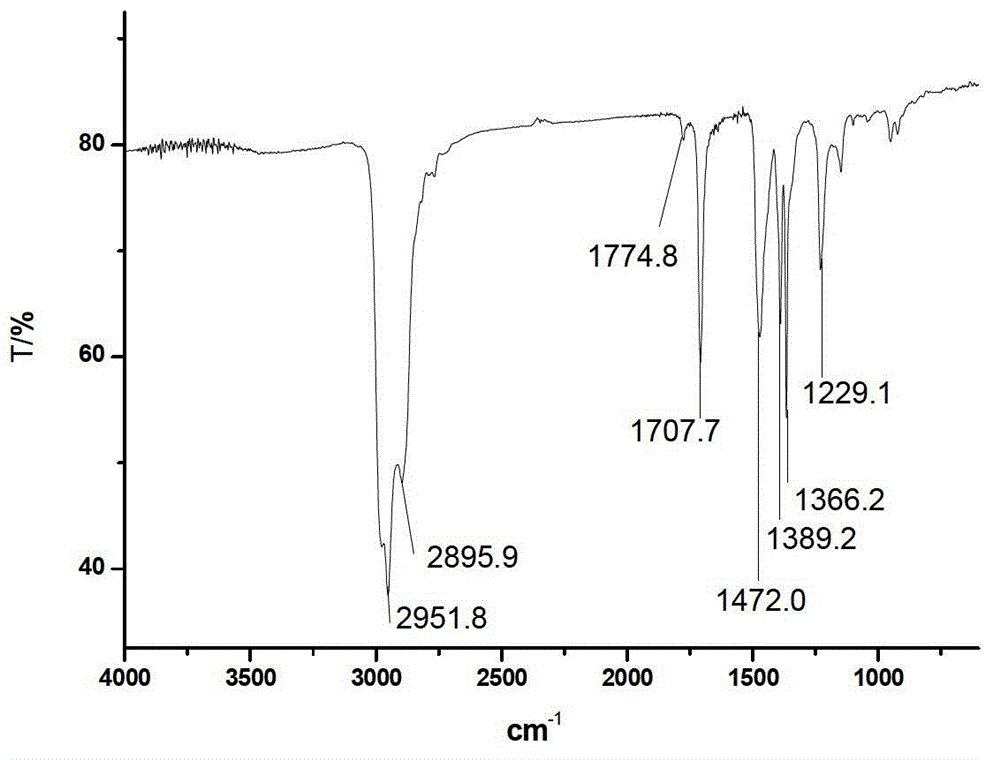

Embodiment 2

[0048] Put 79.5g (0.05mol) of polyisobutylene succinimide prepared according to the method described in Example 1 into the reactor, add 6.1g (0.055mol) of 3-chloro-1,2-propanediol into the dropping funnel, and stir , the temperature was raised to about 80°C, and 3-chloro-1,2-propanediol was added dropwise. After the dropwise addition, the reaction was continued until the amine value was basically unchanged, and the reaction was ended to obtain the emulsifier P2, and 2.6g of base oil was added. , so that the active matter content is about 70%.

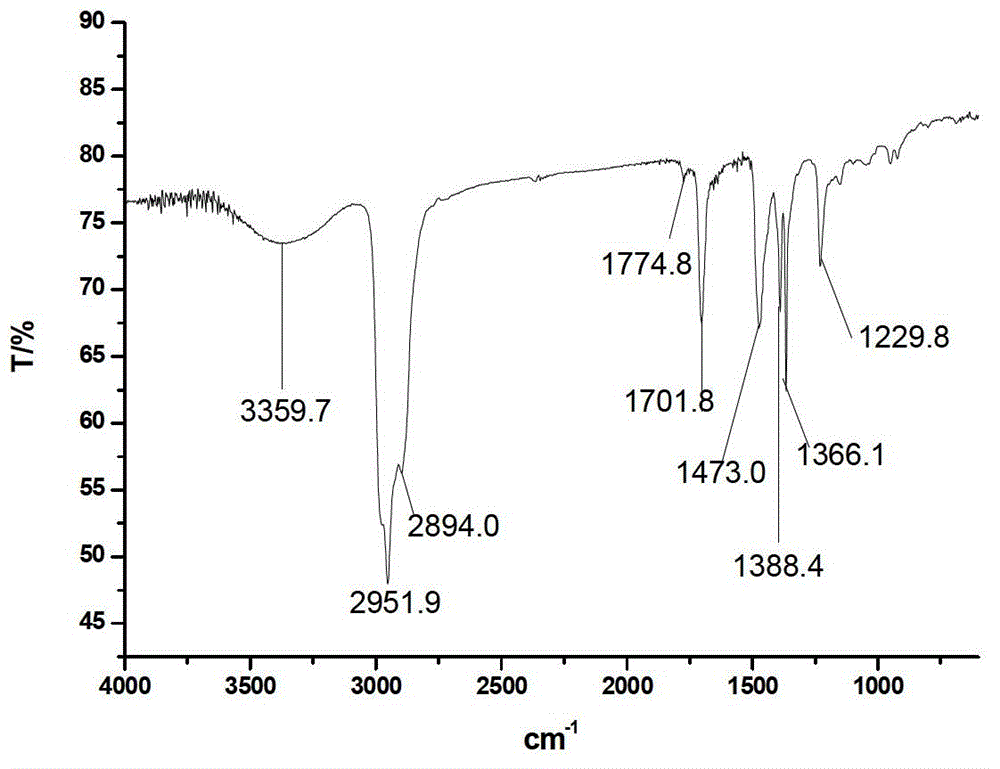

Embodiment 3

[0050] Put 82.4g (0.08mol) of polyisobutylene succinic anhydride (Mn=1030g / mol) with a saponification value of 108.86mg / gKOH, and 80g of n-octane into the reactor, and put N,N-dimethyl-1,3-propane Add 9.0g (0.088mol) of diamine to the dropping funnel, stir, heat up to 50°C, add N,N-dimethyl-1,3-propanediamine dropwise, after the dropwise addition, continue the reaction for 0.5h, Raise the temperature to about 130°C, under the vacuum degree of 0.04MPa, and react until the acid value is basically unchanged, the reaction is terminated, and the solvent is removed to obtain polyisobutylene succinimide.

[0051] Put 55.7g (0.05mol) of polyisobutylene succinimide prepared above, 60g of n-octane, and 30g of isopropanol into the reactor, dissolve 7.0g (0.06mol) of sodium chloroacetate with 15g of water, and add it dropwise Liquid funnel, stirring, heating up to about 80°C, dropwise adding sodium chloroacetate solution, after the dropwise addition, continue to react until the amine valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com