Blasting method for reducing depletion in steeply inclined thin ore body recovery

A thin ore body and steeply inclined technology, applied in the field of blasting, can solve the problems of large ore dilution, achieve the effects of simple blasting process, low dilution rate, and avoid waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

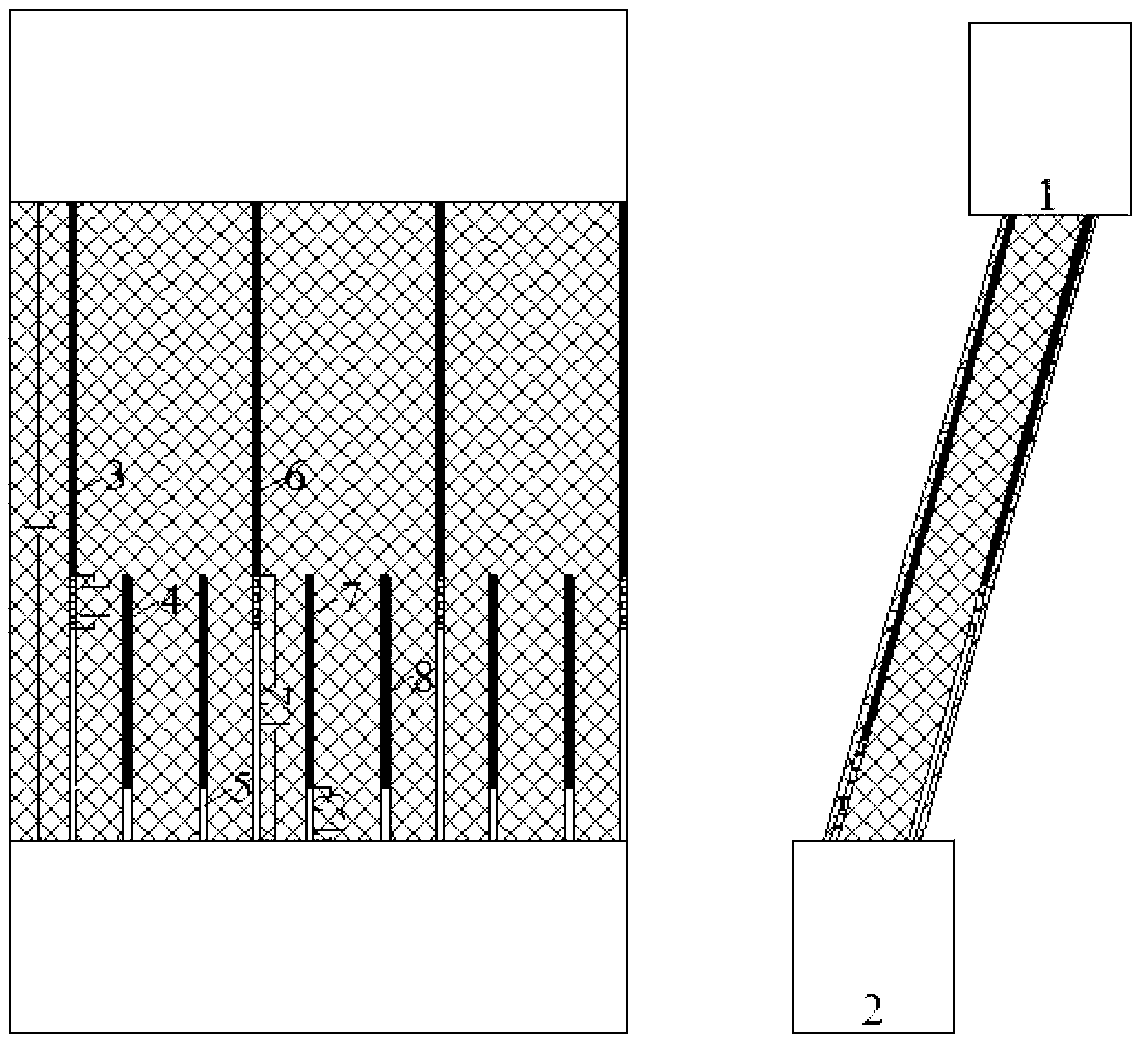

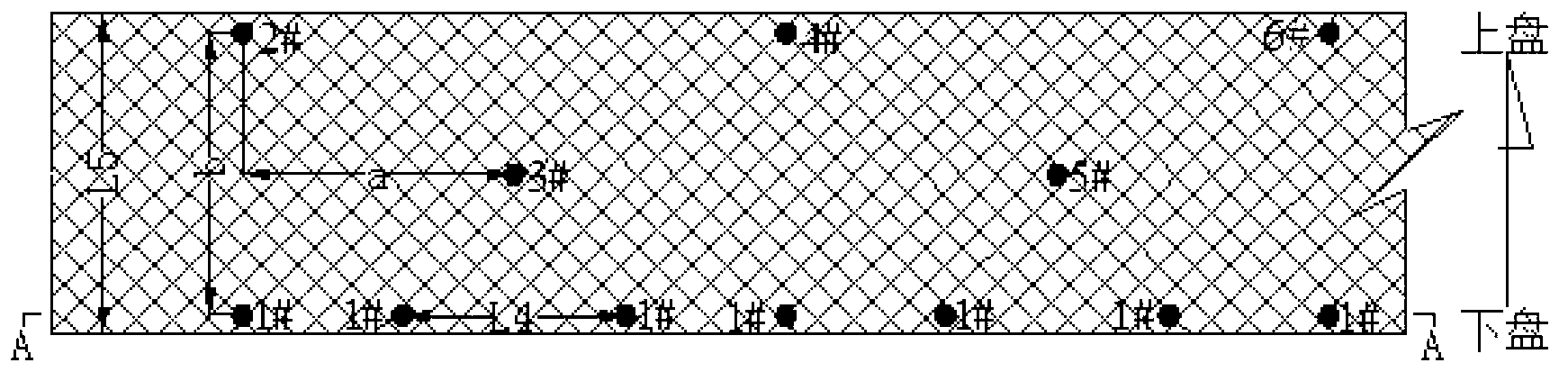

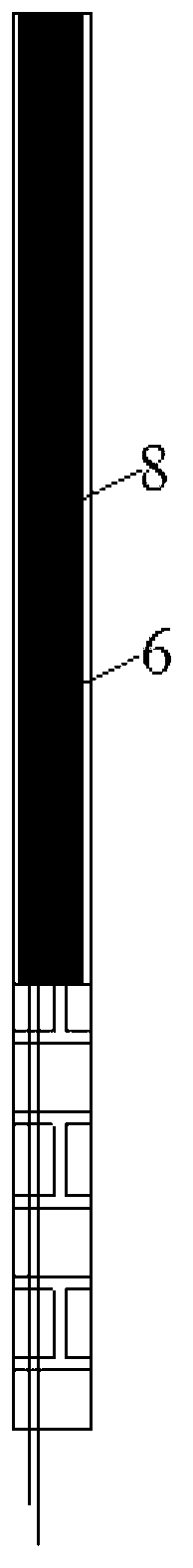

[0027] The combined charge blasting method of the bottom wall consists of 7 parts, namely: 1-upper section along the vein road; 2-lower section along the vein road; 3-recovery charge hole; 4-pre-splitting hole; 5-non-metal filling 6-big drug roll rock water gel explosive; 7-small drug roll rock emulsion explosive; 8-nonel.

[0028] The design steps are:

[0029] (1) Place the holes

[0030] According to the record of the actual measurement position of the ore body and roadway on the Autocad drawing, the site is based on the orientation of the wire, and the total station is used to measure the hole layout points in the lower segment along the vein roadway, especially for fault and bifurcated ore body drilling. Hole positioning is more precise and accurately marked.

[0031] (2) Drilling and inspection

[0032] The marked holes are drilled with the medium and deep hole drilling rig K41X. The inclination angle of the drilled holes is parallel to the ore body inclination. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com