Preparation method of ferroferric oxide and lanthanum-doped bismuth titanate composite magnetoelectric film

A technology of triiron tetroxide and bismuth titanate, which is applied in the field of multiferroic magnetoelectric composite thin film material preparation, can solve the problems of difficult preparation process and oxidation conditions, achieve large remanent polarization, low preparation temperature, and expand the scope of research Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

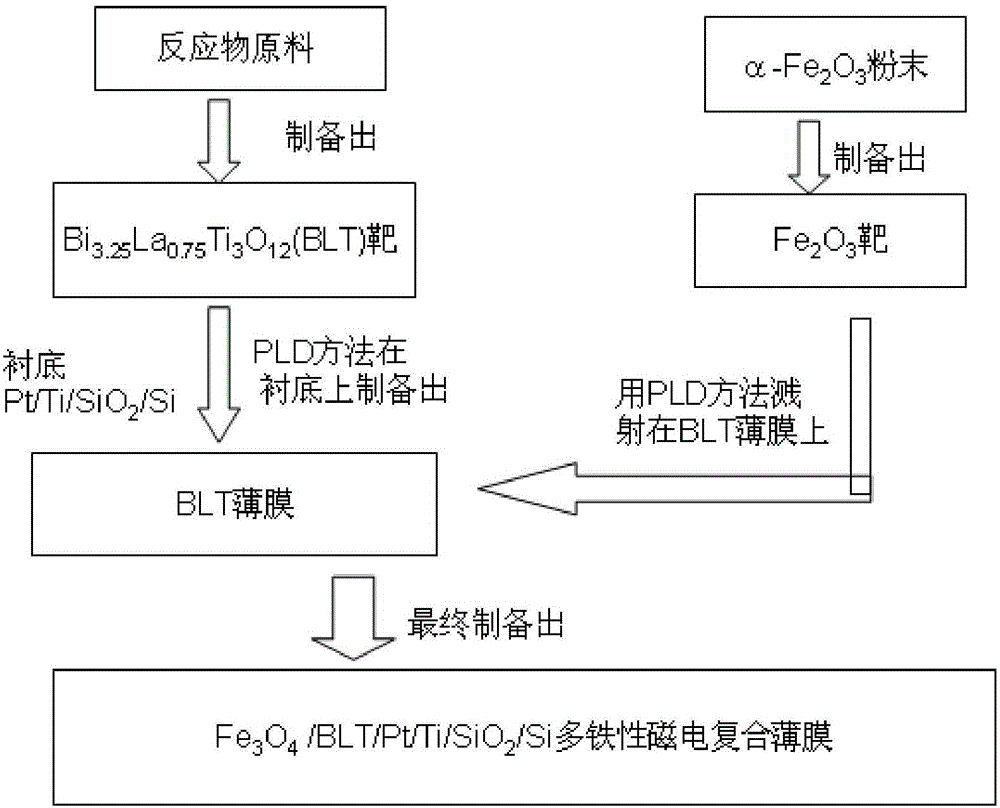

[0022] The preparation method of the ferric oxide and bismuth titanate doped lanthanum composite magnetoelectric thin film of the present invention is characterized in that the method comprises the following steps:

[0023] 1. Preparation of Fe 2 O 3 and Bi 3.25 La 0.75 T i3 O 12 (BLT) target

[0024] 1. Bi 3.25 La 0.75 Ti 3 O1 2 Preparation of (BLT) targets

[0025] a) Ingredients: The reactant raw material is Bi 2 O 3 ,La 2 O 3 , TiO2; the three raw materials are mixed in a molar ratio of 13:3:24. Due to the volatility of Bi, an excess of Bi is generally used in the experiment. 2 O 3 To compensate for the loss of Bi, 5-20% of Bi2O3 is added to the raw material.

[0026] b) Put the mixed raw materials into the agate tank, add acetone into the ball mill tank, add agate balls, seal and fix it on the ball mill, the ball milling time is more than 15h, the longer the grinding time, the finer the BLT powder, and the better the effect.

[0027] c) Press the ground r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com