High-ductility low-shrinkage anti-cracking concrete for bridge deck pavement and preparation method thereof

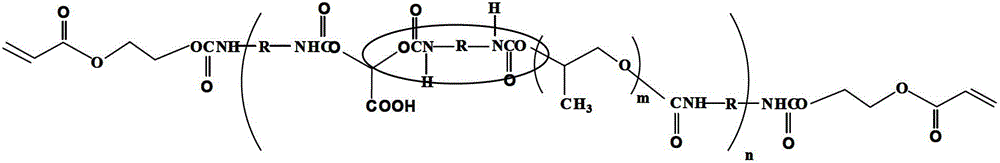

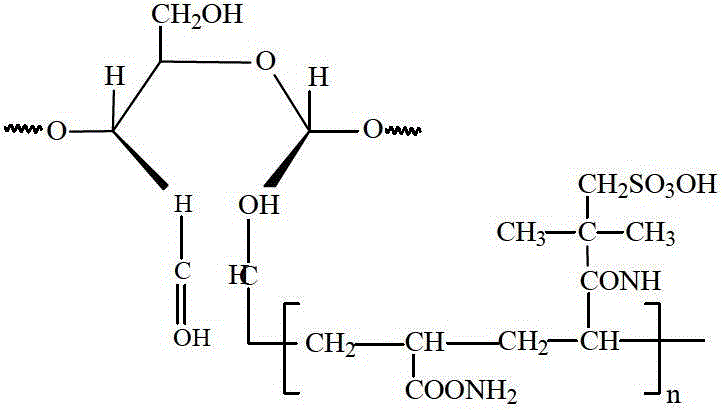

A bridge deck paving, high toughness technology, applied in the field of concrete structural materials, can solve the problems of concrete cracking, different shrinkage values, being stepped down, etc., to reduce local stress concentration, reduce drying shrinkage and self-shrinkage, and improve fracture. The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Mixing ratio of bridge deck pavement concrete in Table 2 Example 1

[0045]

[0046] In embodiment 1: described cement is P.O42.5 ordinary Portland cement.

[0047] The coarse aggregate is ordinary crushed stone, the coarse aggregate is continuously graded from 5 to 25 mm, and the bulk density of the coarse aggregate is 1500 to 1700 kg / m 3 , water absorption 0.1% to 1.5%, crushing value index 6% to 16%.

[0048] The fine aggregate is river sand, the fineness modulus of the fine aggregate is 2.8, and the bulk density of the fine aggregate is 1500-1800kg / m 3 .

[0049] Select the raw materials according to the raw material ratio in Table 2, pour the cementitious material, coarse aggregate, fine aggregate, internal curing agent and hybrid fiber into the concrete mixer for dry mixing for 30 seconds, then add water, water reducing agent and shrinkage reduction and toughening agent, and continue mixing for 60-120s to obtain high-toughness, low-shrinkage, crack-resistant...

Embodiment 2

[0051] Table 3 Mixing ratio of bridge deck pavement concrete in Example 2

[0052]

[0053] In Example 2: the cement is P.O42.5 ordinary Portland cement, and the fineness modulus of the fine aggregate is 2.8; the coarse aggregate is 5-25mm continuous grade match.

[0054] Select raw materials according to the ratio of raw materials in Table 3, pour cementitious material, coarse aggregate, fine aggregate, internal curing agent and hybrid fiber into the concrete mixer for dry mixing for 30 seconds, then add water, water reducer and shrinkage reduction and toughening agent, and continue mixing for 60-120s to obtain high-toughness, low-shrinkage, crack-resistant concrete for bridge deck paving (that is, to obtain high-toughness, low-shrinkage, crack-resistant, dense and homogeneous bridge deck concrete). Its physical performance technical indicators and durability performance technical indicators are listed in Table 5 and Table 6.

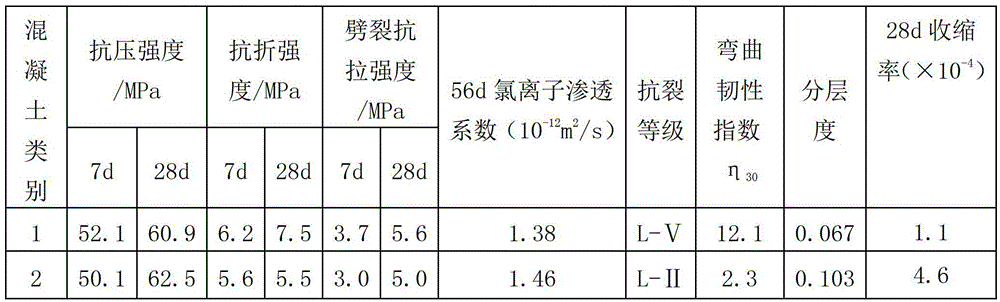

Embodiment 3

[0056] Table 4 Mixing ratio of bridge deck pavement concrete in Example 3

[0057]

[0058] In Example 3: the cement is P.O42.5 ordinary Portland cement, and the fineness modulus of the fine aggregate is 2.8; the coarse aggregate is 5-25mm continuous grade match.

[0059] Select the raw materials according to the raw material ratio in Table 4, pour the cementitious material, coarse aggregate, fine aggregate, internal curing agent and hybrid fiber into the concrete mixer for dry mixing for 60 seconds, then add water, water reducing agent and shrinkage reduction and toughening agent, and continue mixing for 60-120s to obtain high-toughness, low-shrinkage, crack-resistant concrete for bridge deck paving (that is, to obtain high-toughness, low-shrinkage, crack-resistant, dense and homogeneous bridge deck concrete). Its physical performance technical indicators and durability performance technical indicators are listed in Table 5 and Table 6.

[0060] Table 5 Technical indicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com