Forced external circulating type efficient precipitation method and equipment based on addition of lime

A technology of high-efficiency sedimentation and high-efficiency sedimentation tank, which is applied in the field of forced external circulation high-efficiency sedimentation with lime addition and its equipment, can solve the problems of low removal rate of COD and suspended solids, failure to meet recycling standards, and high operating costs. Achieve the effect of good effluent water quality, less chemical consumption and high sludge solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

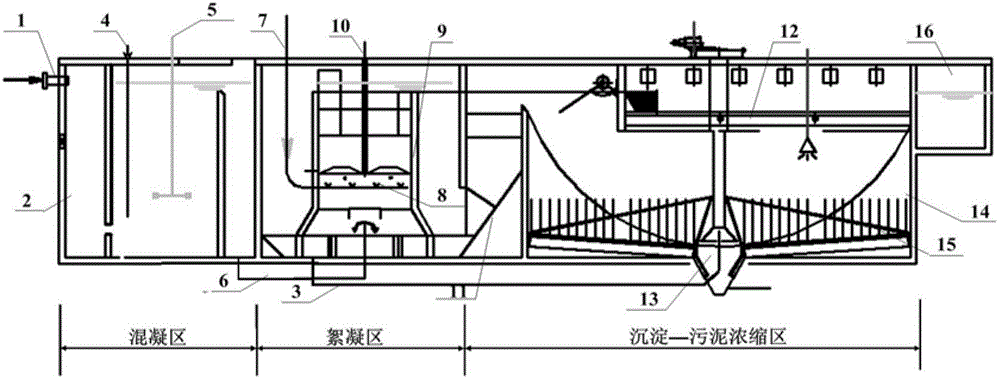

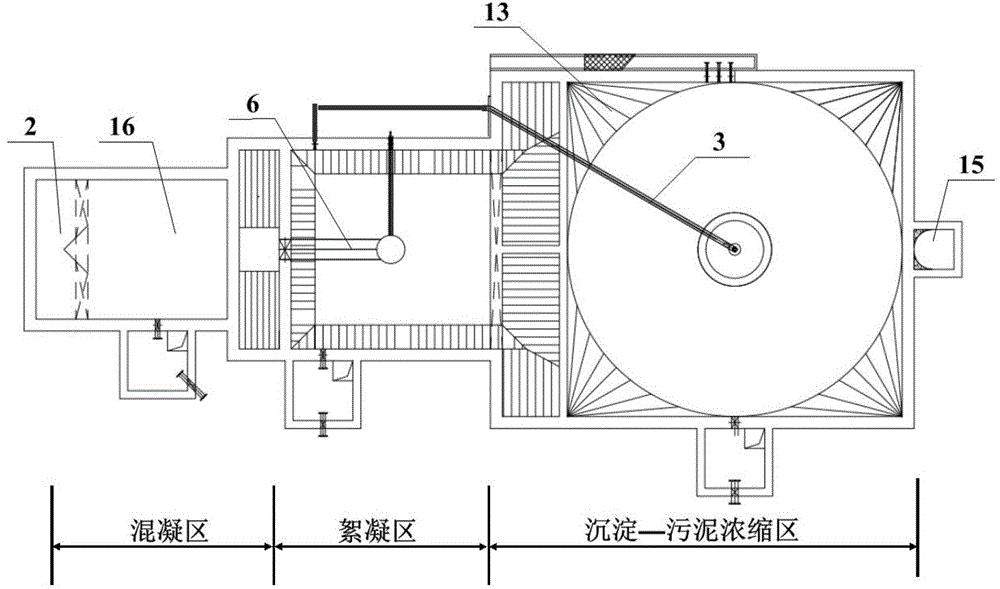

[0026] Below in conjunction with accompanying drawing, the present invention will be further described:

[0027] The high-efficiency sedimentation tank in the present invention is divided into three parts: a coagulation tank, a flocculation tank, and a sedimentation-sludge concentration tank, and the three parts are connected to each other. see figure 1 , The sewage first enters the high-efficiency sedimentation tank and enters the micro-vortex hydraulic mixer 2 through the water inlet pipe 1, and the micro-vortex hydraulic mixer plays the role of adjusting the water volume. The sewage passing through the micro-vortex hydraulic mixer enters the coagulation tank from the bottom, and the automatic dosing device 4 is used to add lime to the coagulation tank, and the dosage is automatically adjusted according to the water inflow. A common dosing room is set up at the operation site to store medicines, and it is equipped with a liquid medicine dispensing system, and the added lime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com