Door guard plate tool appliance for vehicle

A door guard and tooling technology, which is applied in the field of vehicle door guard tooling, can solve problems such as low space utilization, door outer panel rework, and lack of limit devices, so as to reduce the workload of repair and improve work efficiency , The effect of convenient operation for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

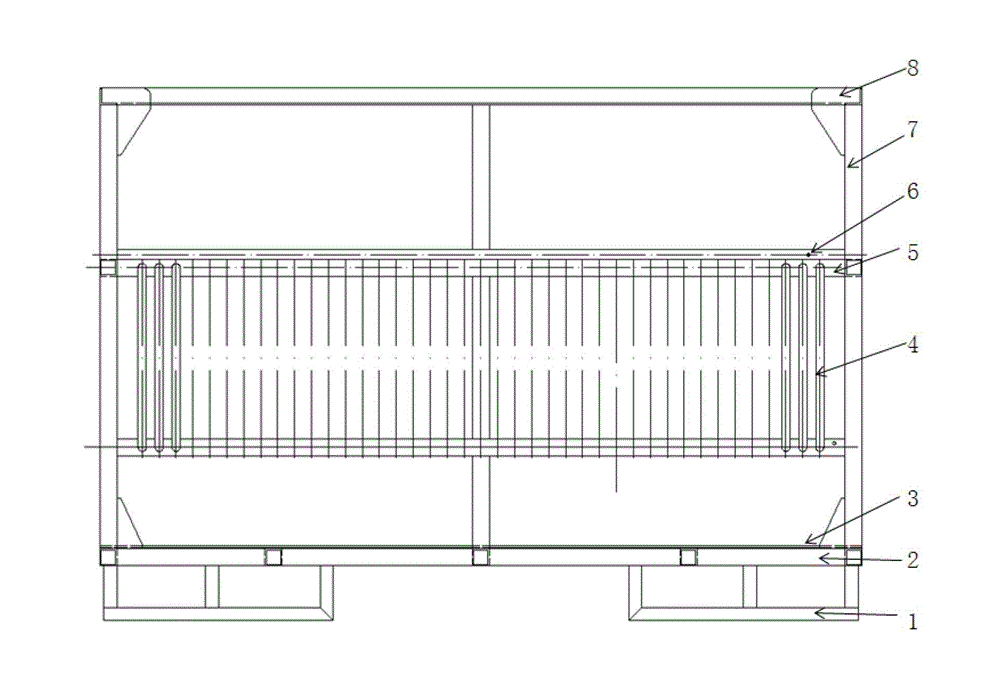

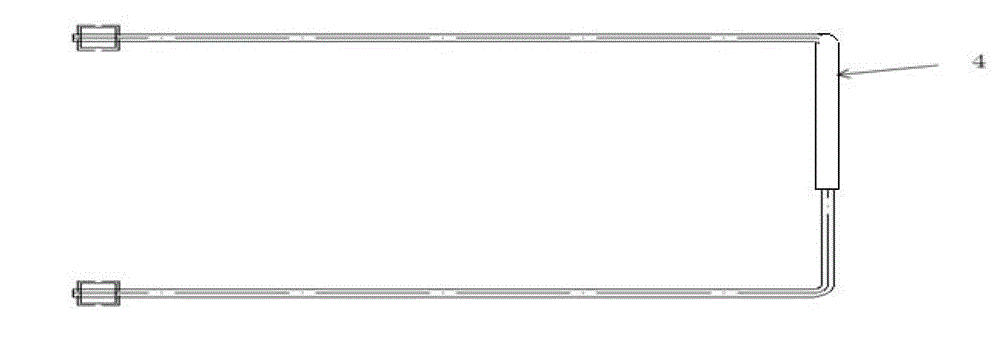

[0029] Such as Figure 1-2 The technical solution provided by the present invention is a vehicle door guard plate tooling device, including a frame, the frame is composed of a bottom frame 2, a pillar 7 and an angle steel 8, the bottom frame 2, the pillar 7 and the The angle steels 8 are connected in sequence, the frame is provided with a protection device and a limit device, and the protection area of the protection device is adjustable in size. The protective device is a U-shaped gear lever 4, the U-shaped gear lever 4 is composed of a three-section protective arm, including a bottom protective arm, two side protective arms, the bottom protective arm and the two side protective arms form a "U" shape. The two ends of the bottom protection arm are respectively connected with the two side protection arms by welding. A sleeve structure is arranged in the middle of the bottom protection arm, one end of the bottom protection arm is connected with the inner sleeve, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com