Draft-sleeping structure of tank car without central beam

A technology for railways and tank cars, which is applied in the field of pillow structure of railway tank cars without center girder. It can solve the problems of poor fatigue resistance and high vertical weld stress, and achieve the effects of reducing stress concentration, increasing fatigue life and improving fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

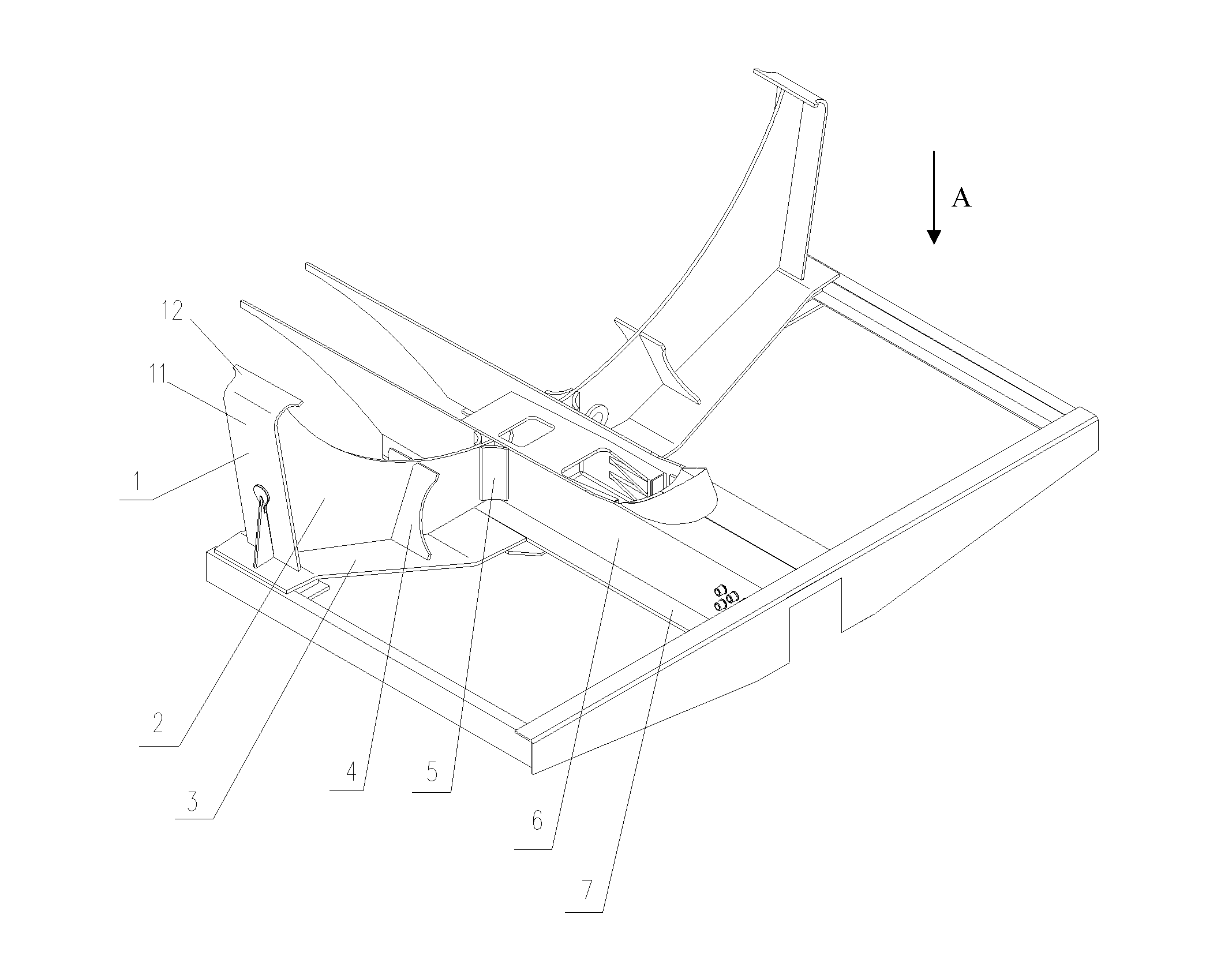

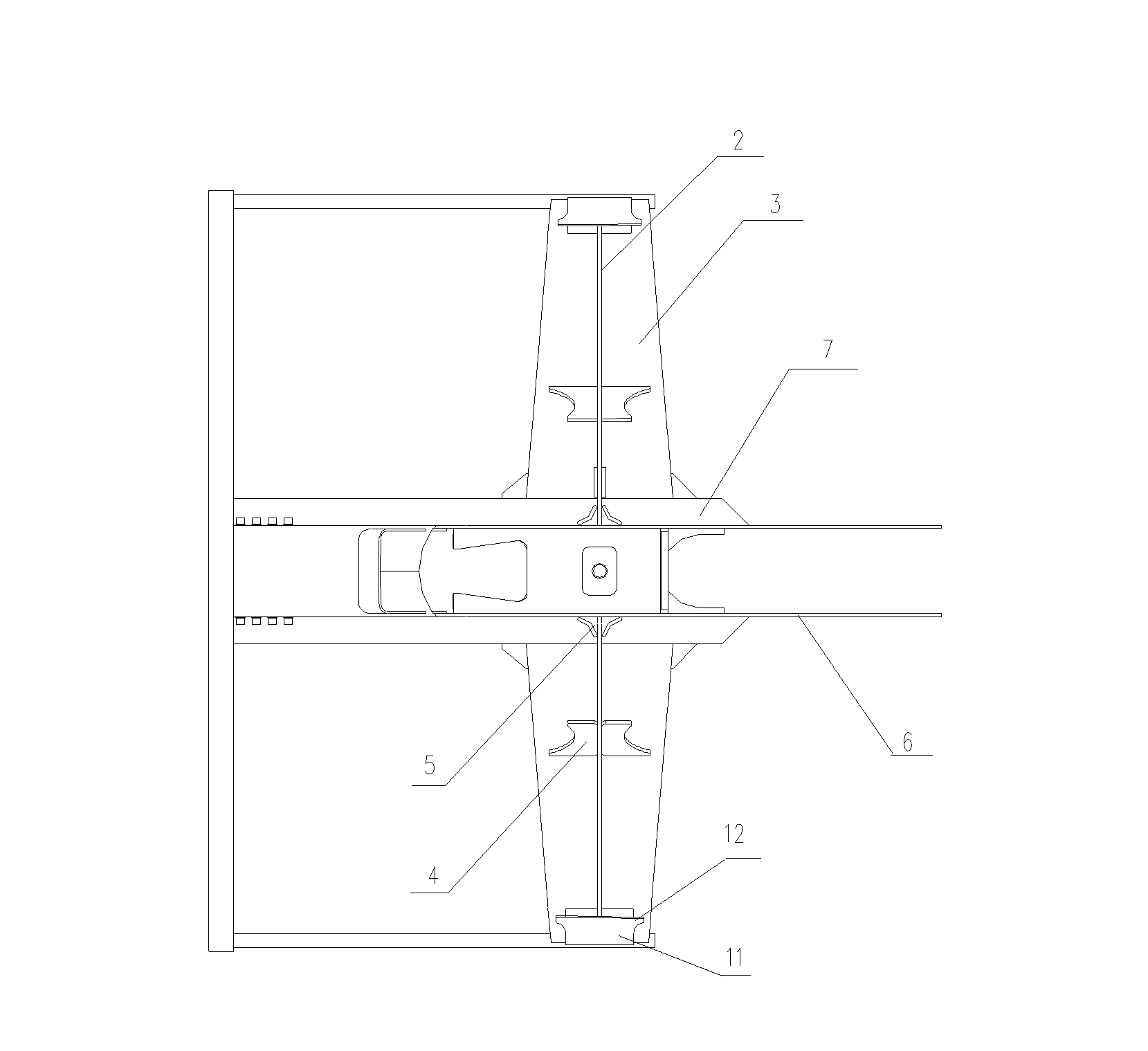

[0020] see figure 1 , figure 2 , the traction pillow structure of a railway tank car without a central sill of the present invention, comprising a corbel side cover 1, a corbel web 2, a corbel lower side cover 3, a corbel rib 4, a reinforcing member 5, and a traction beam web 6 and the lower wing surface 7 of the traction beam; the corbel web 2 is set on the lower side cover plate 3 of the corbel; the traction beam web 6 is perpendicular to the traction beam lower wing surface 7; the corbel rib 4 is set on the bolster The beam lower side cover plate 3 is close to the longitudinal rib of the bending area of the traction beam.

[0021] The reinforcing piece 5 is a steel plate bent into an arc shape, which is similar to the shape of a tile. The corbel web 2 and the traction beam web 6 are connected by vertical welds. On both sides of the seam, the two straight sides of each tile-shaped reinforcement are respectively connected with the corbel web 2 and the traction beam web 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com