Feeder of small type short fiber packing machine

A technology of feeder and short fiber, applied in the direction of presses, manufacturing tools, etc., can solve problems such as low speed, inconvenient maintenance, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

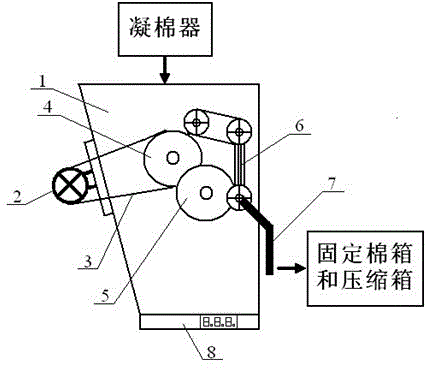

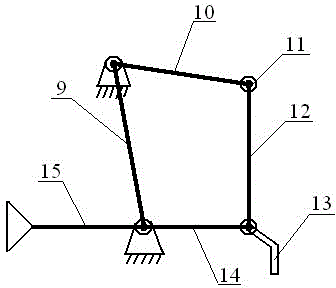

[0017] figure 1 It is a structural schematic diagram of a feeder for a small-sized short fiber baler according to an embodiment of the present invention; the structure of the feeder includes a casing 1, a transmission mechanism, a connecting rod mechanism 6, rake teeth 7 and an electrical control device 8, and the transmission mechanism Installed outside the casing 1, it is composed of a motor 2, a transmission belt 3, a chain, a pulley 4 and a sprocket 5, the linkage mechanism 6 is installed inside the casing 1, and the rake teeth 7 are mounted on the connecting On the connecting rod 13 of the rod mechanism 6, the electrical control device 8 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com