Electrical tar precipitator

A technology of electric tar catcher and power supply, applied in the field of electric tar catcher, can solve the problems of low life, unstable operation, shutdown, cleaning and maintenance, etc., and achieve the effects of convenient maintenance, easy operation and avoidance of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

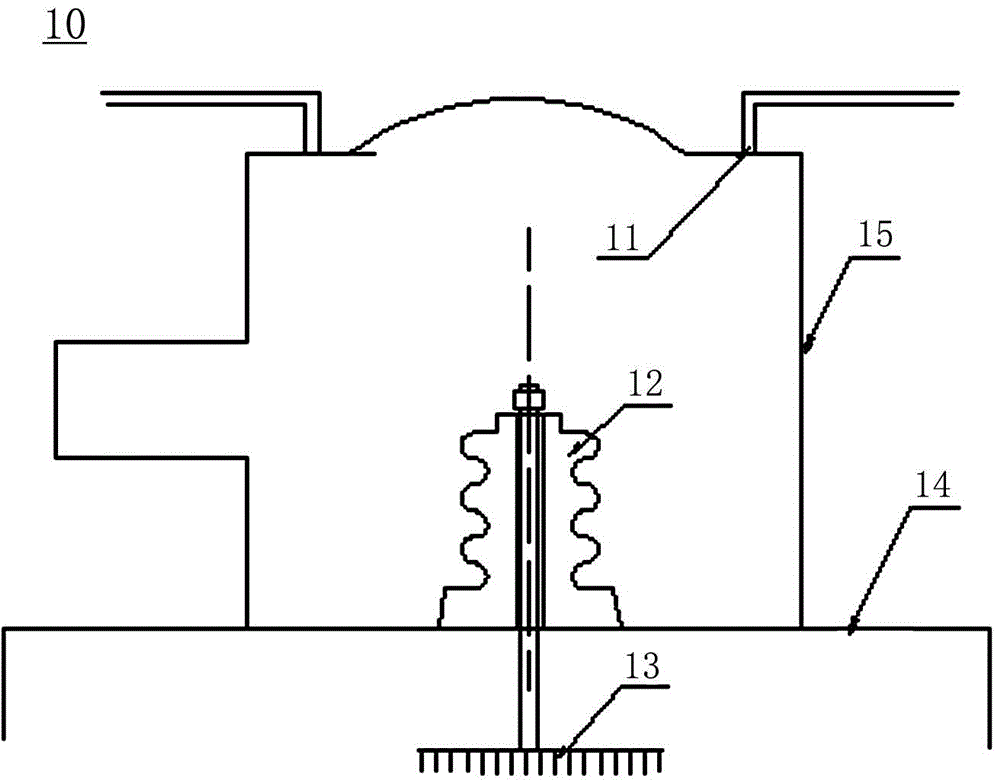

Image

Examples

Embodiment Construction

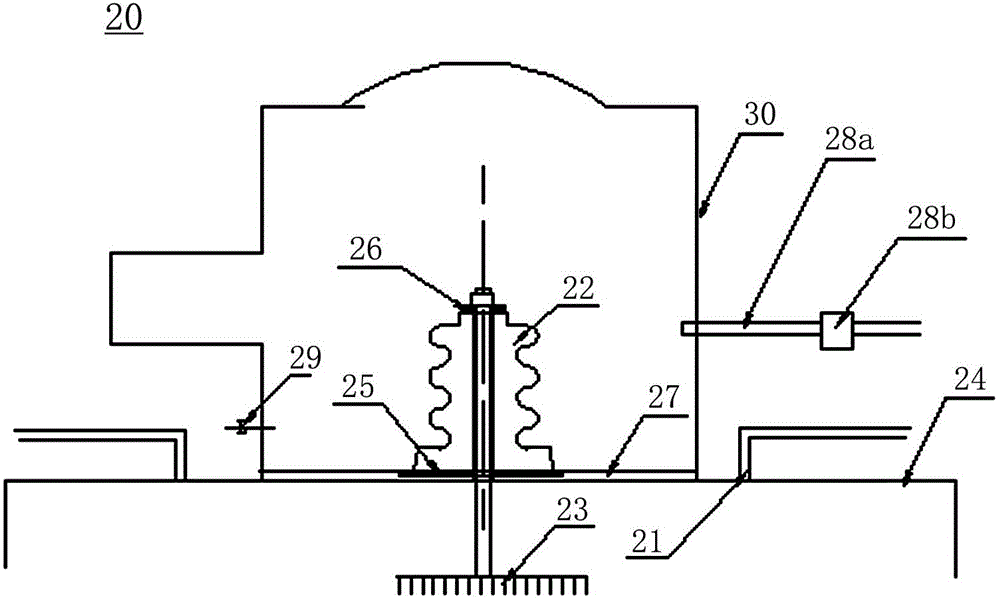

[0019] Hereinafter, an exemplary embodiment of the electric tar catcher of the present invention will be described in detail with reference to the accompanying drawings.

[0020] figure 2 A schematic structural view of an electric tar catcher according to an exemplary embodiment of the present invention is shown.

[0021] Such as figure 2 As shown, in this exemplary embodiment, the electric tar catcher includes a coke catch tank body 24, a power porcelain bottle box 30, a high-pressure porcelain bottle 22, a high-pressure porcelain bottle 23, a sealing assembly and a spraying device.

[0022] Among them, the high-voltage porcelain bottle 22 is arranged in the power porcelain bottle box 30 , the high-voltage porcelain bottle 23 is arranged in the coke-catching tank body 24 and is connected with the high-voltage porcelain bottle 22 , and the power supply porcelain bottle box 30 is arranged above the coke-catching tank body 24 . High-pressure porcelain bottle 23 is many. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com