Nickel-aluminum oxide catalysis complex membrane, preparation method thereof and application thereof

An aluminum oxide and composite membrane technology, which is applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Time and other issues, to achieve the effect of simple use of equipment, time-saving preparation process, and fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of nickel-aluminum trioxide catalytic composite film, specifically comprises the following steps:

[0035] (1) Put the 90mm×60mm×250μm porous through-hole anodized aluminum film into a 500mL beaker, add 420mL of pure water, clean it with ultrasonic waves for 30min, take out the aluminum oxide film, dry it in an oven at 100°C for 0.5h, and Burn in a high-temperature furnace at 800°C for 5 hours, take out the aluminum oxide film and cool to room temperature;

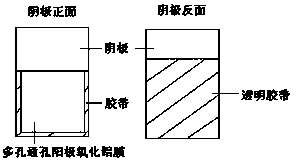

[0036] (2) Use scotch tape to paste the above-mentioned porous through-hole anodized aluminum film to be plated on the electrolytic nickel plate of 150mm×60mm×2mm, and stick the scotch tape on the reverse side of the electrolytic nickel plate, specifically as follows figure 1 As shown, that is, the porous through-hole anodized aluminum film to be plated above is first placed on one end of a 150mm×60mm×2mm electrolytic nickel plate, and then the porous through-hole anodized aluminum film...

Embodiment 2

[0044] A kind of preparation method of nickel-aluminum trioxide catalytic composite film, specifically comprises the following steps:

[0045] (1) Put the 90mm×60mm×250μm porous through-hole anodized aluminum film into a 500mL beaker, add 420mL of pure water, clean it with ultrasonic waves for 5min, take out the aluminum oxide film, dry it in an oven at 50°C for 5h, and dry it at 1100°C Burn in a high-temperature furnace at ℃ for 0.5h, take out the aluminum oxide film and cool to room temperature;

[0046] (2) Paste the above-mentioned porous through-hole anodized aluminum film to be plated on a 150mm×60mm×2mm electrolytic copper plate with double-sided adhesive tape, and paste a transparent tape on the reverse side of the electrolytic copper plate;

[0047] (3) Add 400g of nickel chloride, 50g of oxalic acid, 50g of glycolic acid, and 300g of potassium chloride into a 2L beaker, add 985mL of water to dissolve, and form a mixture of nickel chloride-oxalic acid-glycolic acid-po...

Embodiment 3

[0054] A kind of preparation method of nickel-aluminum trioxide catalytic composite film, specifically comprises the following steps:

[0055] (1) Put the 90mm×60mm×250μm porous through-hole anodized aluminum film into a 500mL beaker, add 420mL of pure water, clean it with ultrasonic waves for 17min, dry it in an oven at 85°C for 2h, and burn it in a high-temperature furnace at 900°C Burn for 3 hours, take out the aluminum oxide film and cool to room temperature;

[0056] (2) Paste the above-mentioned porous through-hole anodized aluminum film to be plated on a steel plate of 150mm×60mm×2mm with scotch tape, and stick the scotch tape on the reverse side of the steel plate;

[0057] (3) Add 300g nickel nitrate, 25g tartaric acid, 25g lactic acid, 70g potassium chloride, 80g ammonium chloride into a 2L beaker, add 985mL water to dissolve, and form nickel nitrate-tartaric acid-lactic acid-potassium chloride-ammonium chloride The mixed solution was adjusted to a pH value of 4.5 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com