Yogurt tablet and preparation method thereof

A technology for yogurt flakes and skim milk, which is applied in milk preparations, dairy products, applications, etc., can solve the problems of easy discoloration of products, shortened product shelf life, difficult to control moisture, etc., and achieves easy control of microbial indicators and improved product qualification rate. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

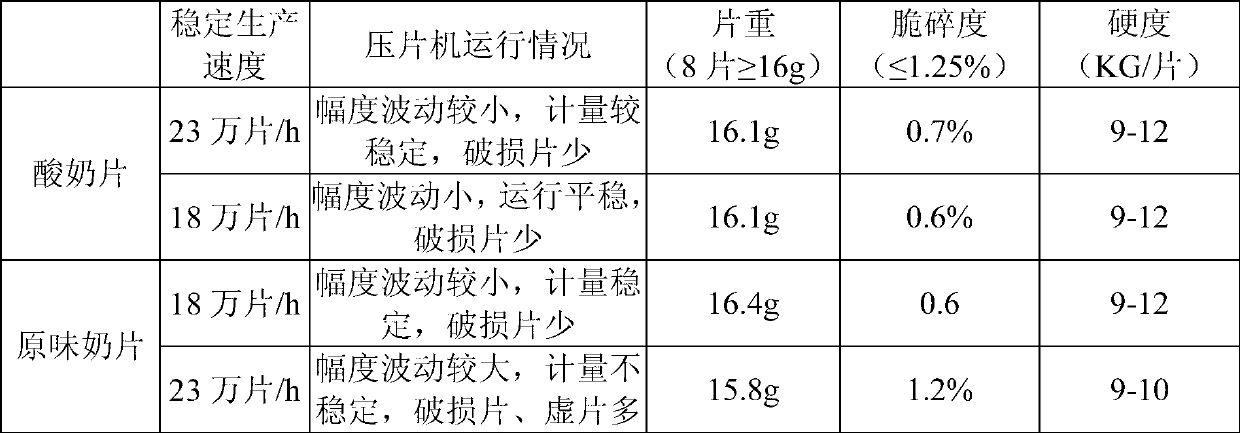

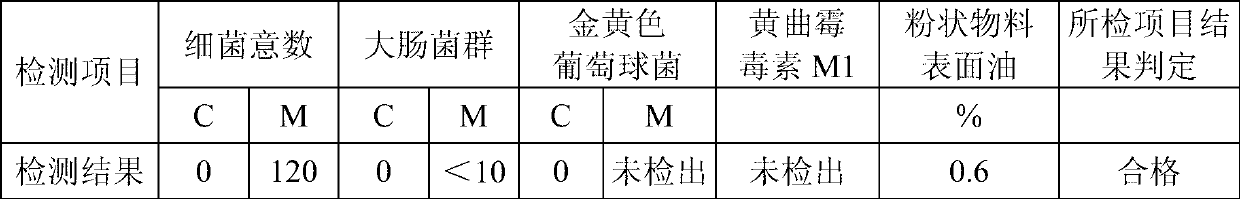

Examples

Embodiment 1

[0050] This embodiment provides a yogurt tablet and a preparation method thereof.

[0051] Taking the weight of the yogurt sheet as 100%, the raw material of the yogurt sheet consists of: milk 370% (dry matter content 11.8wt%); whey powder 6%; white granulated sugar 5%; vegetable oil 10%; glucose syrup 10% ( dry matter content 75% by weight); skimmed milk powder 17.59%; essence 0.15%; silicon dioxide 0.1%; modified starch 10%.

[0052] The preparation method of this yogurt sheet comprises the following steps:

[0053] 1. Fermentation: Raw milk passes the inspection and is filtered and sterilized and put into the fermenter; add the bacteria into the fermenter and mix for 15 minutes to make the bacteria evenly distributed. Fermentation is terminated when the pH value is 4.2, and the stirring is started for demulsification Processing, stirring time is 3 minutes;

[0054] 2. Carburetion: Put the vegetable oil into the carburetor, start stirring, and heat up to 68-70°C until it i...

Embodiment 2

[0062] This embodiment provides a yogurt tablet and a preparation method thereof.

[0063] Taking the weight of the yogurt sheet as 100%, the raw material of the yogurt sheet consists of: milk 500% (dry matter content 11.8%); whey powder 5%; white granulated sugar 7%; vegetable oil 6.2%; glucose syrup 20% (dry Substance content 75%); Skimmed milk powder 3.46%; Essence 0.1%; Silicon dioxide 0.15%; Modified starch 4%.

[0064] The preparation method of this yogurt sheet comprises the following steps:

[0065] 1. Fermentation: Raw milk passes the inspection and is filtered and sterilized and put into the fermenter; add the bacteria into the fermenter and mix for 15 minutes to make the bacteria evenly distributed. Fermentation is terminated when the pH value is 4.2, and the stirring is started for demulsification Processing, stirring time is 3 minutes;

[0066] 2. Carburetion: Put the vegetable oil into the carburetor, start stirring, and heat up to 68-70°C until it is completel...

Embodiment 3

[0074] This embodiment provides a yogurt tablet and a preparation method thereof.

[0075] Taking the weight of the yogurt sheet as 100%, the raw material of the yogurt sheet consists of: milk 250% (dry matter content 11.8%); whey powder 14.05%; white granulated sugar 3%; vegetable oil 12%; glucose syrup 15% (dry Substance content 75%); skimmed milk powder 22%; strawberry fruit powder 3%; silicon dioxide 0.2%; modified starch 5%.

[0076] The preparation method of this yogurt sheet comprises the following steps:

[0077] 1. Fermentation: Raw milk passes the inspection and is filtered and sterilized and put into the fermenter; add the bacteria into the fermenter and mix for 15 minutes to make the bacteria evenly distributed. Fermentation is terminated when the pH value is 4.2, and the stirring is started for demulsification Processing, stirring time is 3 minutes;

[0078] 2. Carburetion: Put the vegetable oil into the carburetor, start stirring, and heat up to 68-70°C until i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com