Electrode sensor and use of electrode sensor as EIT electrode

An electrode sensor, effective electrode technology, applied in the direction of sensors, applications, electrocardiography, etc., can solve the problems of lack of electrical contact performance, wear performance, expensive electrode support structure, low acceptance by patients and testers, medical personnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0158] While the invention is susceptible to embodiments in many different forms, preferred embodiments of the invention are shown in the drawings and will be described in detail herein, with the understanding that the specification is considered as exemplifying the principles of the invention and not It is intended to limit the invention in its broad aspects to the specific embodiments shown.

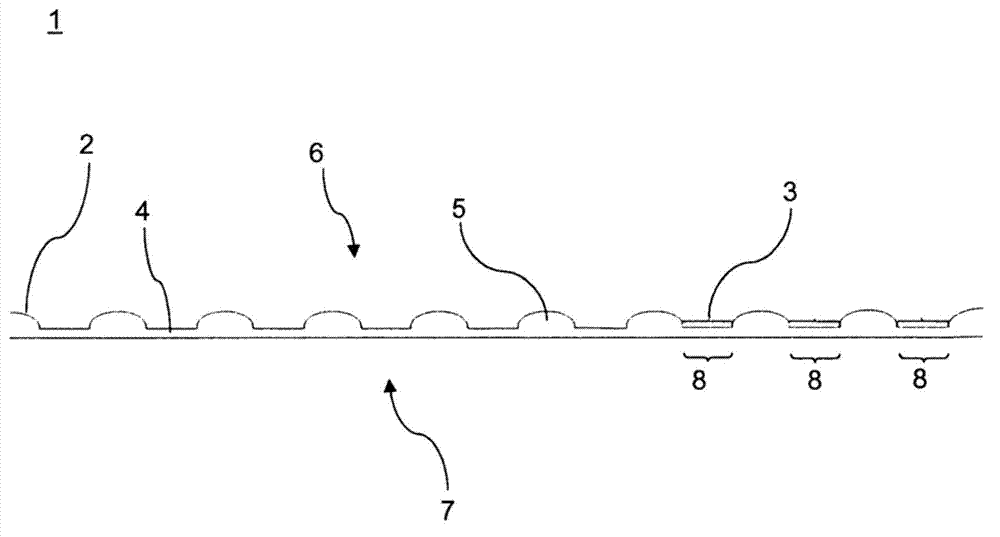

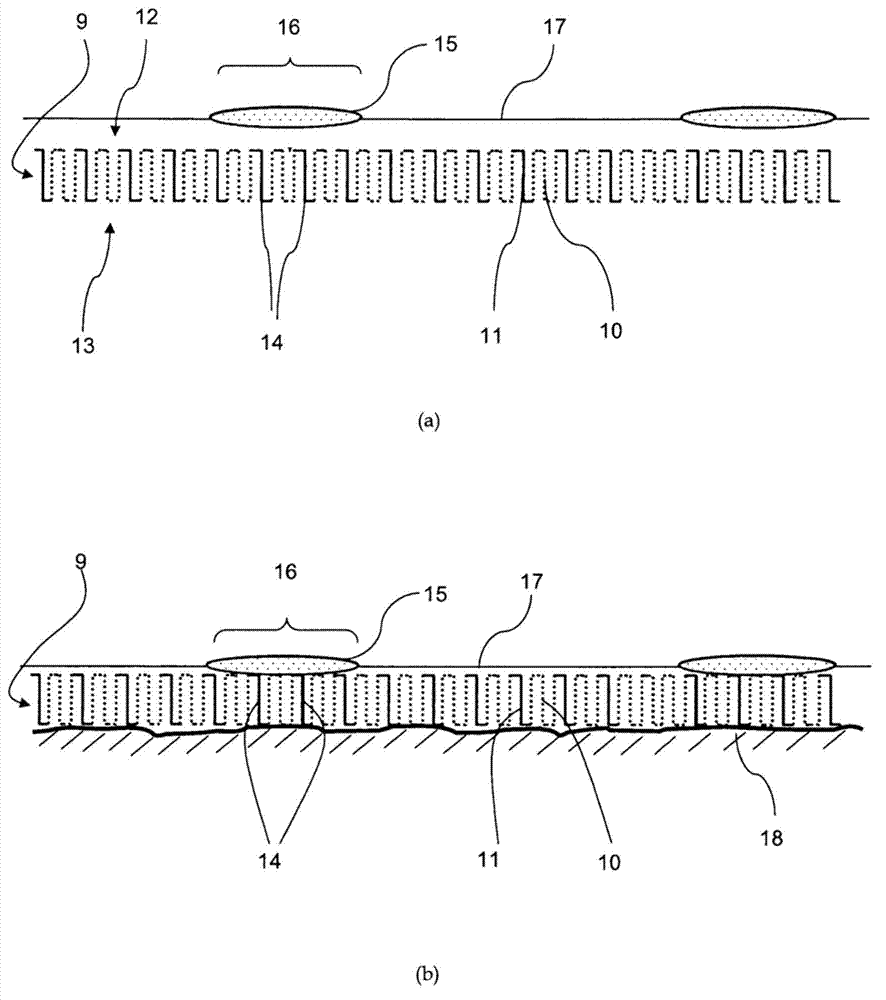

[0159] exist figure 1 A strip-shaped or strip-shaped structure 1 comprising electrically conductive foam material 2 and contact elements 3 is shown in longitudinal section. The foam material 2 consists, for example, of a conductive polymer or a polymeric material with conductive inclusions. The foam material forms compressed areas 4 and non-compressed areas 5 . Compressed regions 4 exhibit increased density relative to non-compressed regions 5 . Compressed areas 4 are separated from one another by non-compressed areas 5 . The contact element 3 is located on the compression zone 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com