Chemical luminous sensor and method for detecting glucose by employing chemical luminous sensor

A chemiluminescence and sensor technology, which is applied in the direction of chemiluminescence/bioluminescence, and analysis by making materials undergo chemical reactions, can solve the problems of reduced enzyme activity and inability to fix on the same column, so as to achieve simple operation and broaden the scope of chemistry. Luminescence reaction conditions and effects of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation method of chemiluminescence sensor:

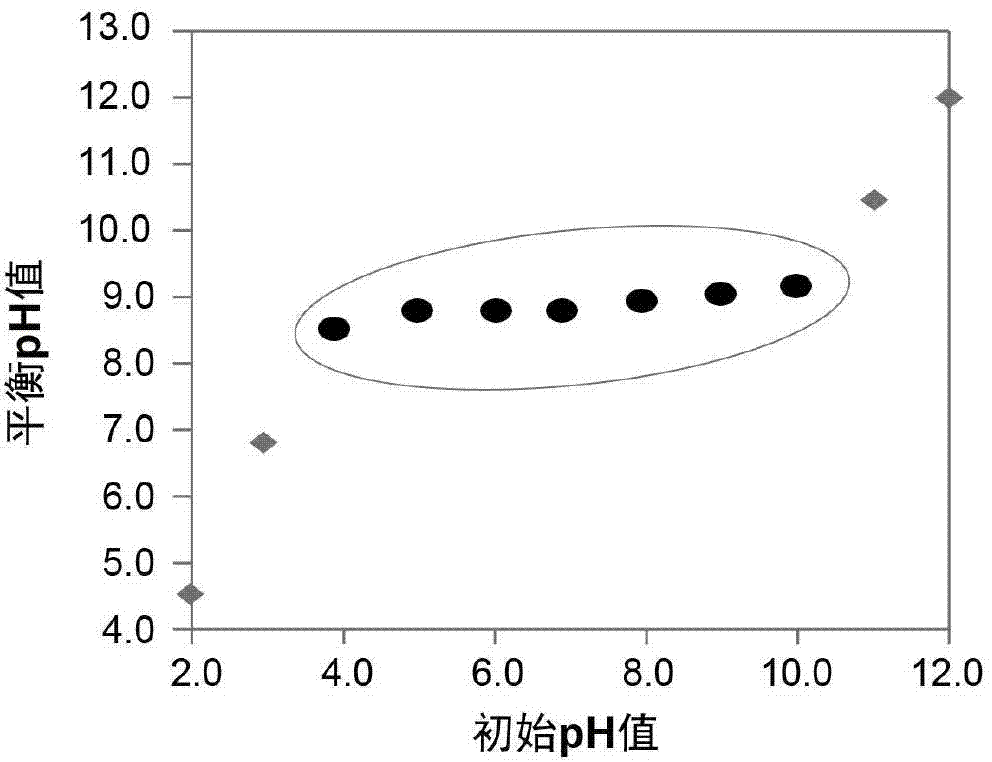

[0020] A: Weigh 0.03mol of magnesium nitrate and 0.015mol of aluminum nitrate, mix them, add 60mL of pure water, and prepare salt solution; weigh 0.0075mol of sodium carbonate and 0.12mol of sodium hydroxide, mix, add 60mL of pure water, Prepared into lye. Put the above two solutions drop by drop into the four-neck flask, stir, and control the pH value of the mixture between 9.0-10.5. After the dropwise addition, the four-necked bottle was placed in a 60°C water bath for 24 hours of crystallization. The product was centrifuged, washed and dried to obtain magnesium aluminum carbonate hydrotalcite ([Mg 4 Al 2 (OH) 12 ]CO 3 ·yH 2 o).

[0021] B: Take 0.1 g of the above-mentioned magnesium aluminum carbonate hydrotalcite and add 5 mL of luminol solution with a concentration of 0.0002 mol / L, absorb for 10 min, filter, and dry at room temperature to obtain a yellow-green product. The mass ratio of magnesium aluminum ca...

Embodiment 2

[0027] Preparation method of chemiluminescence sensor:

[0028] A: Weigh 0.045mol of magnesium nitrate and 0.015mol of aluminum nitrate, mix them, add 60mL of pure water, and prepare salt solution; weigh 0.0075mol of sodium carbonate and 0.12mol of sodium hydroxide, mix, add 60mL of pure water, Prepared into lye. Put the above two solutions drop by drop into the four-neck flask, stir, and control the pH value of the mixture between 9.0-10.5. After the dropwise addition, the four-necked bottle was placed in a 60°C water bath for 24 hours of crystallization. The product was centrifuged, washed and dried to obtain magnesium aluminum carbonate hydrotalcite ([Mg 6 Al 2 (OH) 12 ]CO 3·yH 2 o).

[0029] B: Take 0.1 g of the above-mentioned magnesium aluminum carbonate hydrotalcite and add 15 mL of luminol solution with a concentration of 0.0002 mol / L, absorb for 10 min, filter, and dry at room temperature to obtain a yellow-green product. The mass ratio of magnesium aluminum c...

Embodiment 3

[0034] Preparation method of chemiluminescence sensor:

[0035] A: Weigh 0.06mol of magnesium nitrate and 0.015mol of aluminum nitrate, mix them, add 60mL of pure water to prepare a salt solution; weigh 0.0075mol of sodium carbonate and 0.12mol of sodium hydroxide, mix them, add 60mL of pure water, Prepared into lye. Put the above two solutions drop by drop into the four-neck flask, stir, and control the pH value of the mixture between 9.0-10.5. After the dropwise addition, the four-necked bottle was placed in a 60°C water bath for 24 hours of crystallization. The product was centrifuged, washed and dried to obtain magnesium aluminum carbonate hydrotalcite ([Mg 8 Al 2 (OH) 12 ]CO 3 ·yH 2 o).

[0036] B: Take 0.2 g of the above-mentioned magnesium aluminum carbonate hydrotalcite and add 25 mL of luminol solution with a concentration of 0.0002 mol / L, absorb for 10 min, filter, and dry at room temperature to obtain a yellow-green product. The mass ratio of magnesium alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com