A kind of production method of monohydrogen trisodium pyrophosphate

A technology of trisodium monohydrogen pyrophosphate and anhydrous trisodium monohydrogen pyrophosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc. High operability and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

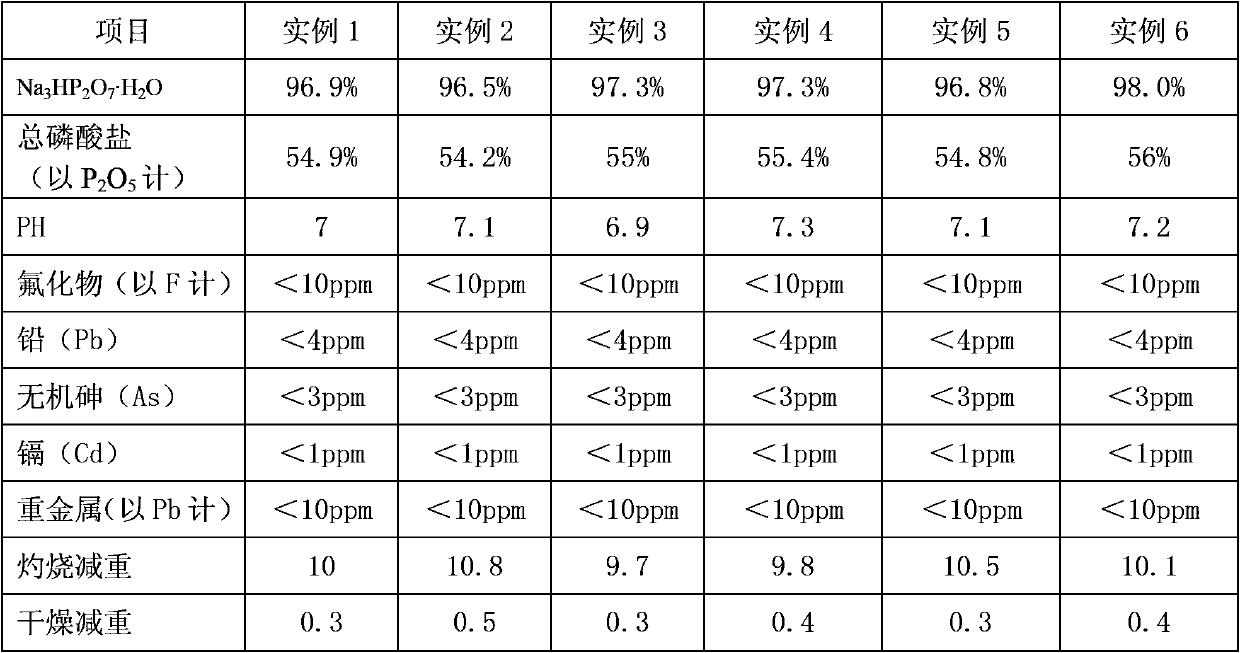

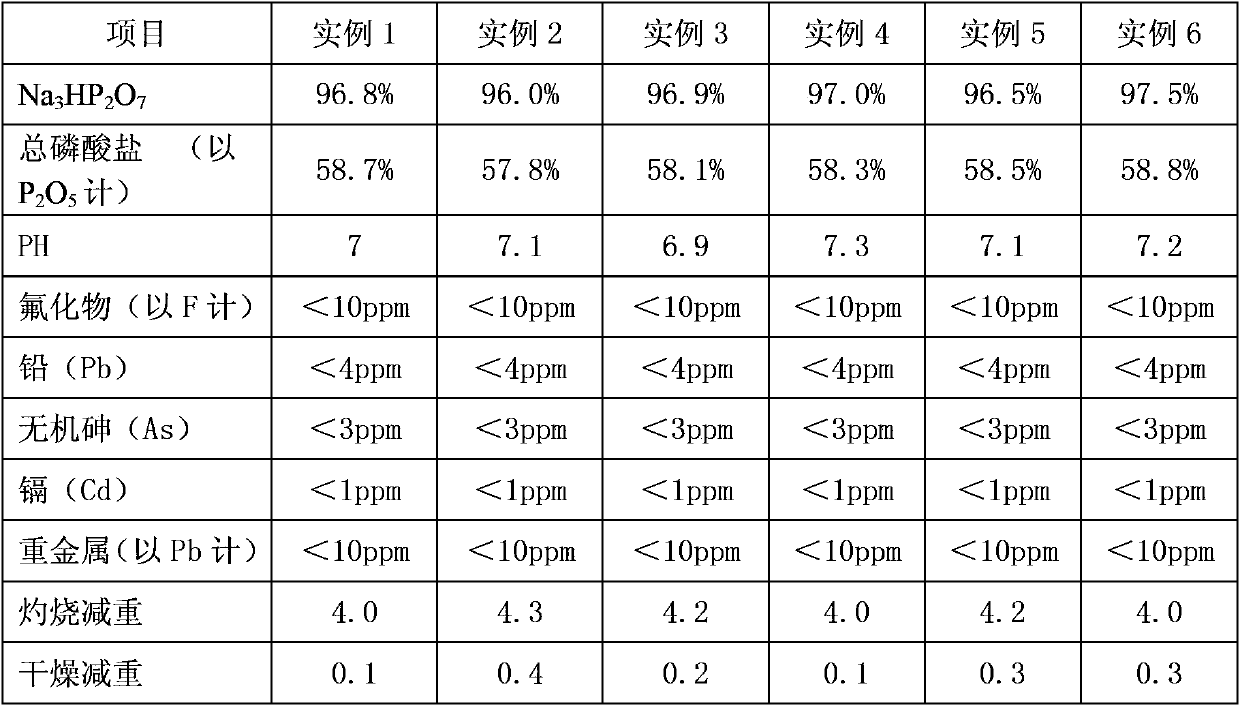

Examples

example 1

[0026] Dissolve 520g of disodium dihydrogen pyrophosphate with a content of 96% into 600ml of distilled water, dissolve 90g of sodium hydroxide in 100ml of hot water, and keep the solution at 60-110°C; continuously stir the sodium hydroxide solution and add dihydrogen pyrophosphate In disodium solution, keep warm for 30min. The solution is cooled to 50°C, centrifuged, and the solid crystalline substance is dried, the temperature is controlled at 105-160°C, and the drying time is 2-4h to obtain monohydrogen trisodium pyrophosphate monohydrate product. Continue drying at 180-220°C for 2-6 hours to obtain anhydrous trisodium monohydrogen pyrophosphate.

example 2

[0028] Dissolve 520g of disodium dihydrogen pyrophosphate with a content of 96% into 700ml of distilled water, and the solution is heated to 60-110°C; 119.3g of sodium carbonate is added with continuous stirring, and after the insulation reaction for 30min, the solution is cooled to 50°C for centrifugation. The solid crystalline substance is dried, the temperature is controlled at 105-160° C., and the drying time is 2-4 hours to obtain monohydrogen trisodium pyrophosphate monohydrate product. Continue drying at 180-220°C for 2-6 hours to obtain anhydrous trisodium monohydrogen pyrophosphate.

example 3

[0030] Take 500g of pyrophosphoric acid (60%) solution, dissolve 337g of sodium hydroxide in 500ml of water, add the sodium hydroxide solution into the pyrophosphoric acid solution with continuous stirring, react for 30min, cool the solution to 50°C and centrifuge, and dry the solid crystalline substance. The temperature is controlled at 105-160°C, and the drying time is 2-4 hours to obtain monohydrogen trisodium pyrophosphate monohydrate product. Continue drying at 180-220°C for 2-6 hours to obtain anhydrous trisodium monohydrogen pyrophosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com