Production method of trisodium pyrophosphate

A technology of monohydrogen trisodium pyrophosphate and anhydrous monohydrogen trisodium pyrophosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of no production process and application research, and achieve convenient process, The effect of strong operability and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

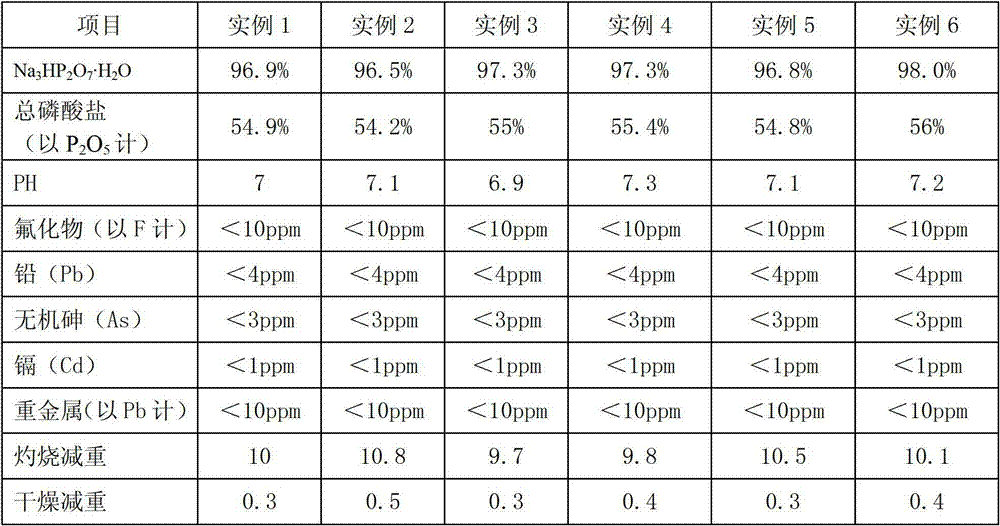

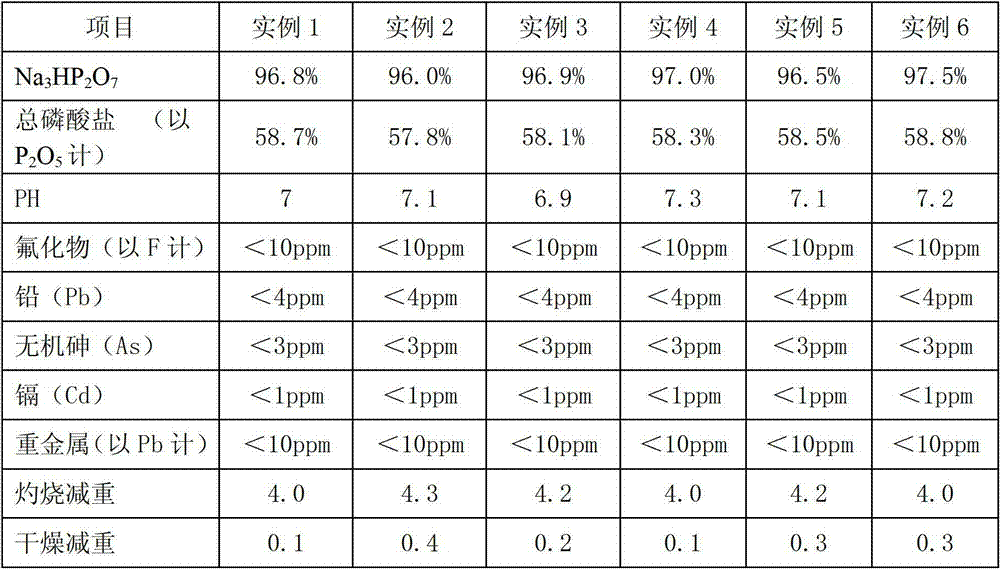

example 1

[0026] Dissolve 520g of disodium dihydrogen pyrophosphate with a content of 96% into 600ml of distilled water, dissolve 90g of sodium hydroxide in 100ml of hot water, and keep the solution at 60-110°C; continuously stir the sodium hydroxide solution and add dihydrogen pyrophosphate In disodium solution, keep warm for 30min. The solution is cooled to 50°C, centrifuged, and the solid crystalline substance is dried, the temperature is controlled at 105-160°C, and the drying time is 2-4h to obtain monohydrogen trisodium pyrophosphate monohydrate product. Continue drying at 180-220°C for 2-6 hours to obtain anhydrous trisodium monohydrogen pyrophosphate.

example 2

[0028] Dissolve 520g of disodium dihydrogen pyrophosphate with a content of 96% into 700ml of distilled water, and the solution is heated to 60-110°C; 119.3g of sodium carbonate is added with continuous stirring, and after the insulation reaction for 30min, the solution is cooled to 50°C for centrifugation. The solid crystalline substance is dried, the temperature is controlled at 105-160° C., and the drying time is 2-4 hours to obtain monohydrogen trisodium pyrophosphate monohydrate product. Continue drying at 180-220°C for 2-6 hours to obtain anhydrous trisodium monohydrogen pyrophosphate.

example 3

[0030] Take 500g of pyrophosphoric acid (60%) solution, dissolve 337g of sodium hydroxide in 500ml of water, add the sodium hydroxide solution into the pyrophosphoric acid solution with continuous stirring, react for 30min, cool the solution to 50°C and centrifuge, and dry the solid crystalline substance. The temperature is controlled at 105-160°C, and the drying time is 2-4 hours to obtain monohydrogen trisodium pyrophosphate monohydrate product. Continue drying at 180-220°C for 2-6 hours to obtain anhydrous trisodium monohydrogen pyrophosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com