Vertical grinding mill

A technology of vertical grinding and grinding zone, applied in the direction of grain processing, etc., can solve the problems of increasing the contact surface of grinding roller and grinding disk, grinding disk and grinding roller wear, small gap between grinding roller and grinding disk, and different thickness of material layer. The effect of less sweeping parts, efficient grinding, and high powder selection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

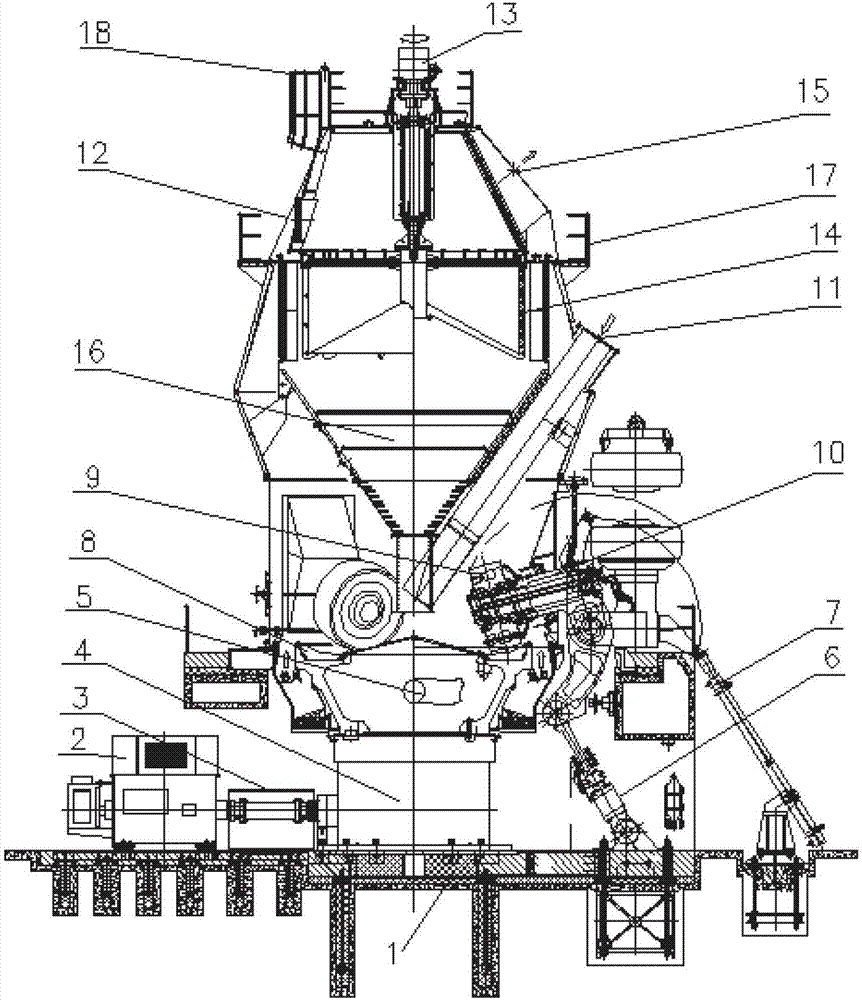

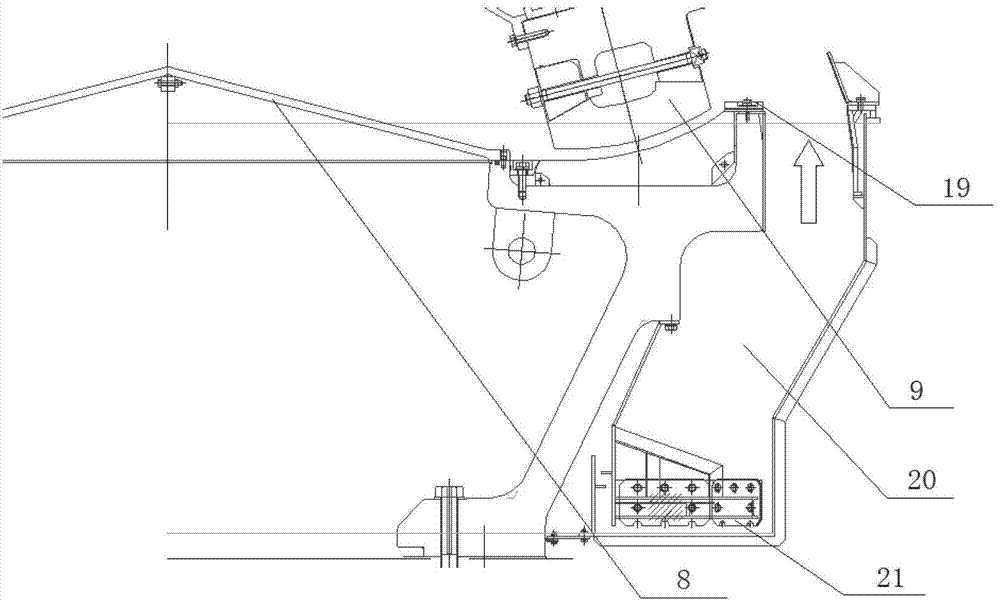

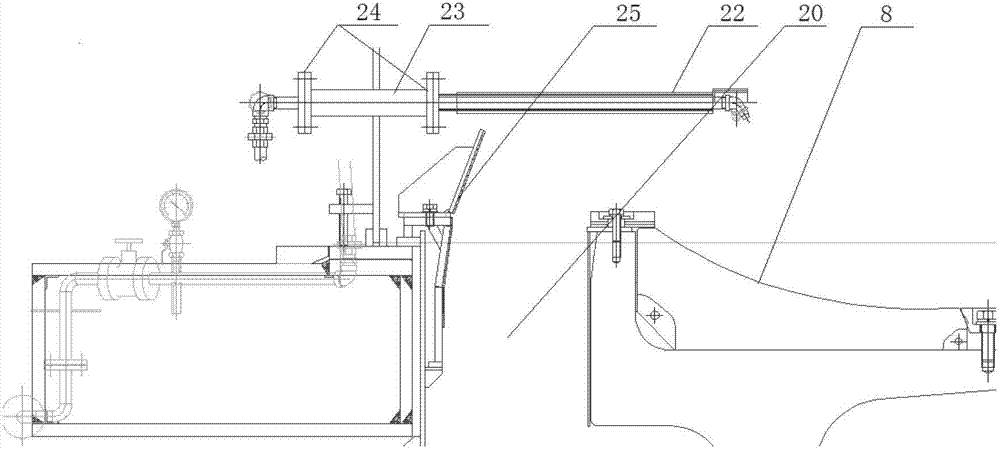

[0025] see figure 1 It can be seen that the vertical mill body is fixed on the concrete foundation 1, and the grinding disc 8 is installed on the reducer 4 at the bottom of the vertical mill body. The reducer 4 is driven by the main motor through the coupling 3, and drives the grinding disc 8 to rotate. The center of the grinding disc 8 is non-grinding area It is in the shape of an upward convex cone, and its edge grinding area (grinding plate liner) is an arc surface that gradually rises outward. The area is conical, and when the material falls on the grinding disc 8, it will enter the surrounding grinding area evenly with the centripetal force of the grinding disc 8 and the sliding force of the cone surface for grinding. The grinding roller 9 is supported by the rocker arm 10, and extends from the side of the vertical mill to the top of the grinding area of the grinding table 8. There are usually four grinding rollers 9, all of which are fixed obliquely downward, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com