Ibuprofen arginine granule and preparation method thereof

The technology of arginine ibuprofen and granules is applied in the directions of anti-inflammatory agents, pharmaceutical formulations, non-central analgesics, etc. Simple, sweet and bioavailable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

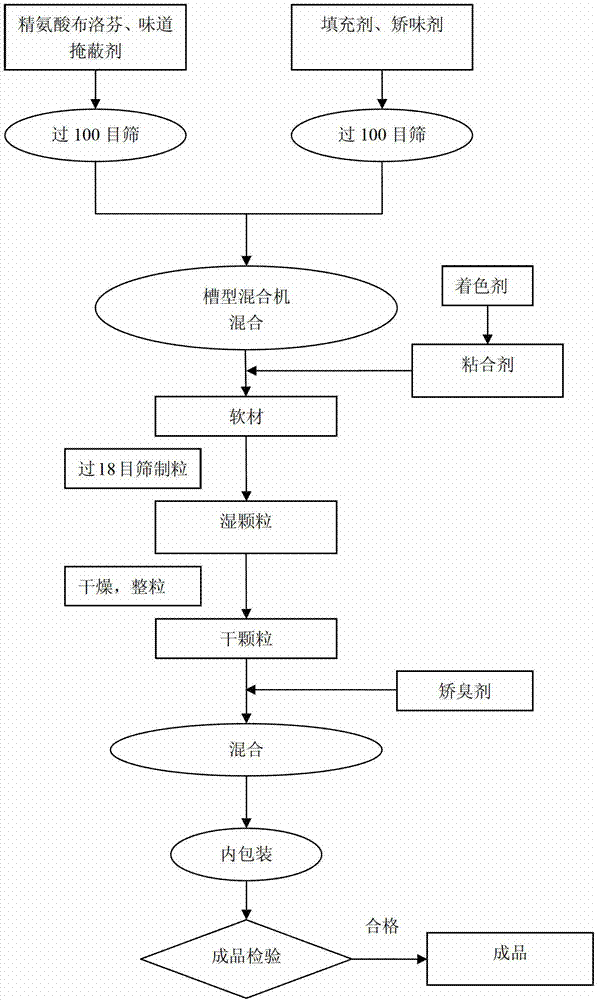

[0067] The detailed screening process of arginine ibuprofen granule of the present invention is as follows:

[0068] 1. Filler screening

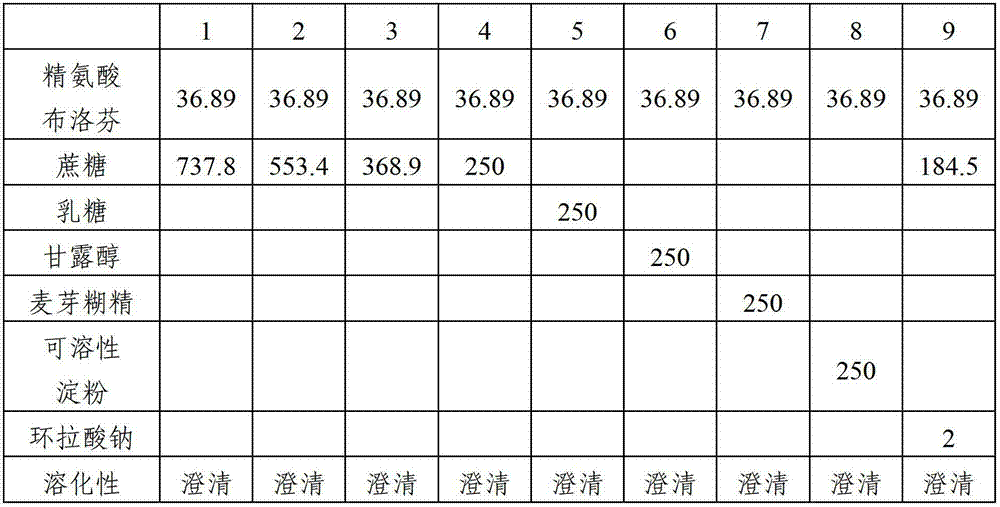

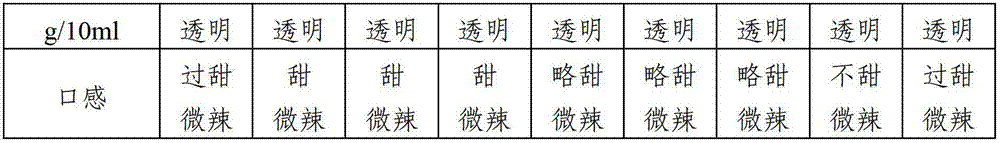

[0069] Arginine ibuprofen has good water solubility, but it has a pungent taste when dissolved in water, so fillers are added to the prescription to observe the solubility and taste changes of the product. The screening results are shown in Table 1.

[0070] Table 1 Screening of fillers (unit: g, packed in 0.2g / bag)

[0071]

[0072]

[0073] Note: The taste participants include 5 adults, 5 males and 5 females, and 5 children (under 12 years old), 5 males and 5 females each.

[0074] Conclusion: Since arginine ibuprofen is easily soluble in water and has a spicy taste when dissolved in water, a filler with good solubility and sweet taste is added. However, the added filler can only be used to form the shape and adjust the sweetness of the solution taste, and cannot completely cover the pungent taste of the raw material drug itself....

Embodiment 2

[0095] Pass arginine ibuprofen, sucrose, hydroxypropyl beta-cyclodextrin and sodium cyclamate through a 100-mesh sieve respectively, and set aside. Weigh the raw and auxiliary materials of the following prescription quantities:

[0096]

[0097] Mix sodium cyclamate and sucrose evenly (mix for 20 minutes), and then mix the resulting mixture with arginine ibuprofen and hydroxypropyl beta cyclodextrin (mix for 30 minutes), then add 2% hypromellose Su K4M 50% ethanol aqueous solution (dissolve hypromellose K4M in 50% ethanol aqueous solution by volume, wherein the mass percent concentration of hypromellose K4M is 2%) to make soft materials, using 18 Mesh sieve granulation, air drying at 60°C for about 2 hours after granulation, granulation with a 16 mesh sieve, mixing the obtained granules with orange flavor for about 3 minutes to obtain arginine ibuprofen granules, after passing the inspection, subpackage into corresponding specifications / bags.

Embodiment 3

[0099] Pass arginine ibuprofen, mannitol, hypromellose K4M, and aspartame through a 100-mesh sieve respectively, and set aside.

[0100] Weigh the raw and auxiliary materials of the following prescription quantities:

[0101]

[0102] Mix aspartame and mannitol evenly (mix for 30 minutes), and then mix the resulting mixture with arginine ibuprofen and hypromellose K4M (mix for 30 minutes), and then add 70% concentration by volume Ethanol aqueous solution is used to make soft material, granulated with 18-mesh sieve, air-dried at 60°C for about 2 hours after granulation, granulated with 16-mesh sieve, and mixed with orange flavor for about 2 minutes to obtain arginine bulo Fen granules, after passing the inspection, are packed into corresponding specifications / bags.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com