Arginine (s)-ibuprofen granules and preparation method thereof

A technology of dextro-ibuprofen and arginine, which is applied in the directions of pharmaceutical formulations, medical preparations without active ingredients, and medical preparations containing active ingredients, etc. preparations, failure to cover up the irritating odor of drugs, and easy deliquescence of arginine ibuprofen tablets, achieving the effects of rapid dissolution, low cost and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Pass arginine dextrobuprofen and hypromellose K4M through 80-mesh sieve respectively, sucrose is crushed and passed through 80-mesh sieve, and set aside.

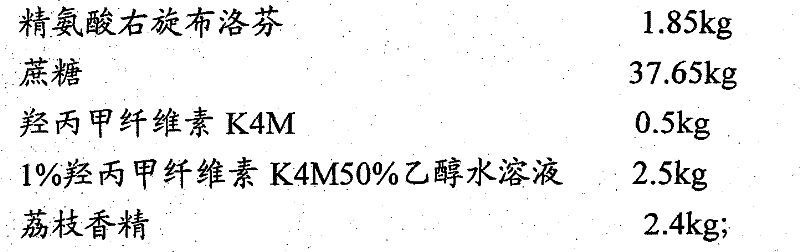

[0062] Weigh the raw materials of the following prescription quantities:

[0063] Dexibuprofen Arginine 1.85kg

[0064] Sucrose 37.65kg

[0065] Hypromellose K4M 0.5kg

[0066] 1% hypromellose K4M 50% ethanol aqueous solution 2.5kg

[0067] Lychee essence 2.4kg.

[0068] Thoroughly mix Dexibuprofen Arginine, Hypromellose K4M, and Lychee Flavor to obtain a mixture. Divide sucrose into 3 parts of equal weight, add the above mixture in 3 times, and mix after each addition. 10 minutes, then add 1% hypromellose K4M50% ethanol aqueous solution (referring to the solution that hypromellose K4M is dissolved in the ethanol aqueous solution of 50% concentration by volume, wherein, hypromellose The mass percent concentration of K4M is 1%) to make soft material, adopt 16 mesh sieves to granulate and then dry at 60 DEG C for ...

Embodiment 2

[0070] Pass arginine dextrobuprofen and povidone K30 through an 80-mesh sieve respectively, and sucrose is crushed and passed through an 80-mesh sieve for later use.

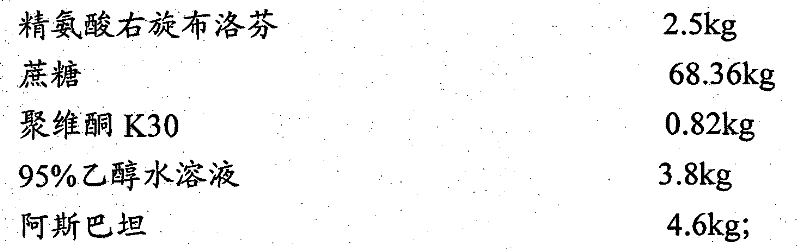

[0071] Weigh the raw materials of the following prescription quantities:

[0072] Dexibuprofen Arginine 2.5kg

[0073] Sucrose 68.36kg

[0074] Povidone K30 0.82kg

[0075] 95% ethanol aqueous solution 3.8kg

[0076] Aspartan 4.6kg.

[0077] Fully mix arginine dextrobuprofen, povidone K30, and aspartame to obtain a mixture. Divide sucrose into 3 parts of equal weight, add the above mixture in 3 times, and mix after each addition. 10 minutes, then add 95% (volume percent concentration) ethanol aqueous solution to make soft material, use 16 mesh sieve to granulate, and blow dry at 80 ℃ for 1 hour, adopt 14 mesh sieve to obtain dextrorotatory arginine after granulation After the ibuprofen granules and intermediates pass the inspection, they are divided into 198800 bags by 400 mg / bag in aluminum-plastic composi...

Embodiment 3

[0079] Pass arginine dextrobuprofen and povidone K30 through 80-mesh sieve respectively, mannitol is crushed and pass through 80-mesh sieve, and set aside.

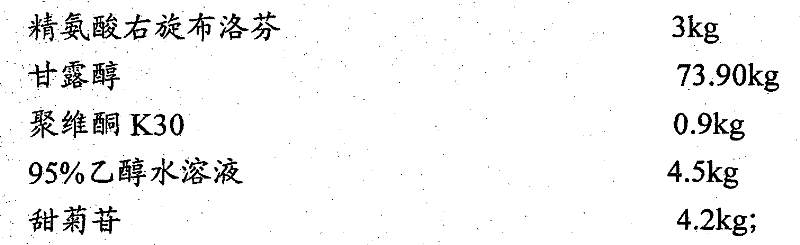

[0080] Weigh the raw materials of the following prescription quantities:

[0081] Dexibuprofen Arginine 3kg

[0082] Mannitol 73.90kg

[0083] Povidone K30 0.9kg

[0084] 95% ethanol aqueous solution 4.5kg

[0085] Stevioside 4.2kg.

[0086] Fully mix arginine dextrobuprofen, povidone K30, and stevioside to obtain a mixture, divide mannitol into 3 parts of equal weight, add the above mixture in 3 times, and mix for 10 minutes after each addition. Minutes, then add 95% (volume percentage concentration) ethanol aqueous solution to make soft material, use 16 mesh sieve to granulate and then blow dry at 65 ℃ for 2.5 hours, adopt 14 mesh sieve to obtain arginine dextrorotatory After the ibuprofen granules and intermediates pass the inspection, they are divided into 215,900 bags by 400 mg / bag in aluminum-plastic composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com