Preparation method and application of pu-erh tea extractive with blood fat reducing function

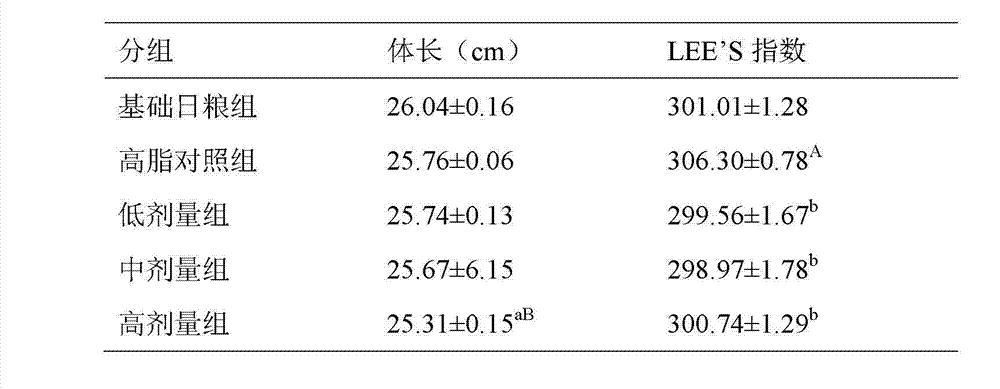

An extract and blood lipid-lowering technology, which is applied in the preparation and application of Pu-erh tea extract with blood-lipid-lowering function, can solve the problems of low Pu-erh tea content, and achieve the goal of controlling weight growth, reducing liver index, and high content of active ingredients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Pu’er tea is decocted and extracted 5 times with water at 100°C, the extraction time is 20 minutes, and the ratio of tea to water is 1:10; the extract is passed through a 20-mesh sieve, adsorbed by macroporous resin D101, and then eluted with 30% ethanol-water solution. The resulting effluent was concentrated under reduced pressure at 80°C to the ratio of tea leaves (weight):concentrate (volume) to 1:3.

[0021] The concentrated solution can be obtained by spray drying. The spray drying conditions are as follows: the inlet air temperature is 160°C, and the outlet air temperature is 80°C.

Embodiment 2

[0023] Pu’er tea is decocted and extracted 4 times with water at 80°C, the extraction time is 60 minutes, and the tea-to-water ratio is 1:8; the extract is passed through a 60-mesh sieve, absorbed by the macroporous resin NKA-9, and washed with 60% ethanol-water solution The resulting effluent was concentrated under reduced pressure at 75°C to tea leaves (weight): concentrated solution (volume) to a ratio of 1:5.

[0024] The concentrated solution can be obtained by freeze-drying. The freeze-drying temperature is -50°C, and the pressure is 0.1Mpa.

Embodiment 3

[0026] Pu’er tea is decocted and extracted 8 times with water at 90°C, the extraction time is 120 minutes, and the tea-to-water ratio is 1:3; the extract is passed through an 80-mesh sieve, adsorbed by macroporous resin NX-9, and washed with 90% ethanol-water solution The resulting effluent was concentrated under reduced pressure at 60°C to tea leaves (weight): concentrate (volume) = 1:2.

[0027] The concentrated solution can be obtained by spray drying. The spraying conditions are as follows: air inlet temperature: 140°C, and air outlet temperature: 70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com