Biaxially oriented polypropylene film, metalized film, and film capacitor

A polypropylene film, biaxially oriented technology, used in capacitors, fixed capacitor dielectrics, fixed capacitor components, etc., can solve the problems of reduced capacitor life, deterioration of vibration characteristics, and high adhesion, and achieve excellent vibration characteristics. , The effect of high withstand voltage and suitable component processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0198] A polypropylene resin ("Borclean (registered trademark)" manufactured by Borealis Co., Ltd.) having an isotactic pentad fraction of polypropylene of 0.985 and a melt mass flow rate (MFR) of 2.6 g / 10 minutes, and internal 3 A branched polypropylene resin (Profax PF-814 manufactured by Basell Co., Ltd., a high melt tension polypropylene) having 3 substituted olefins per 10,000 carbon atoms was mixed. The content of the branched polypropylene resin was 0.5 mass % with respect to the whole mixed resin. This mixed resin was supplied to an extruder having a temperature of 260° C., and was melt-extruded into a sheet form through a T-slot die at a resin temperature of 255° C. This molten sheet was cooled and solidified on a cooling drum with a diameter of 1.2 m maintained at 60°C. The retention time at 115 to 135° C. was 2 seconds as a result of measurement by a radiation thermometer.

[0199] Next, the cooled and solidified sheet was preheated at 130° C., and stretched 4.6 t...

Embodiment 2

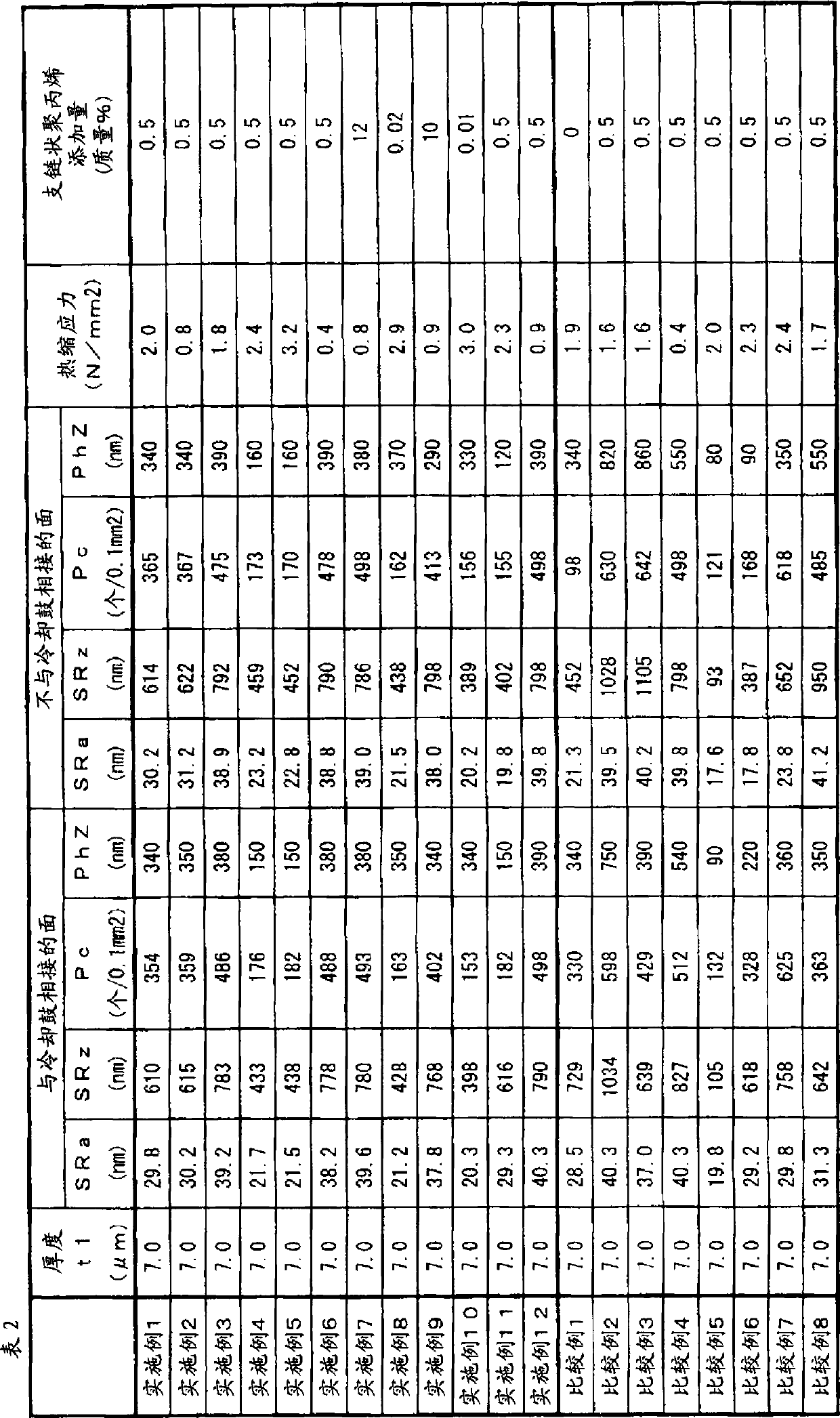

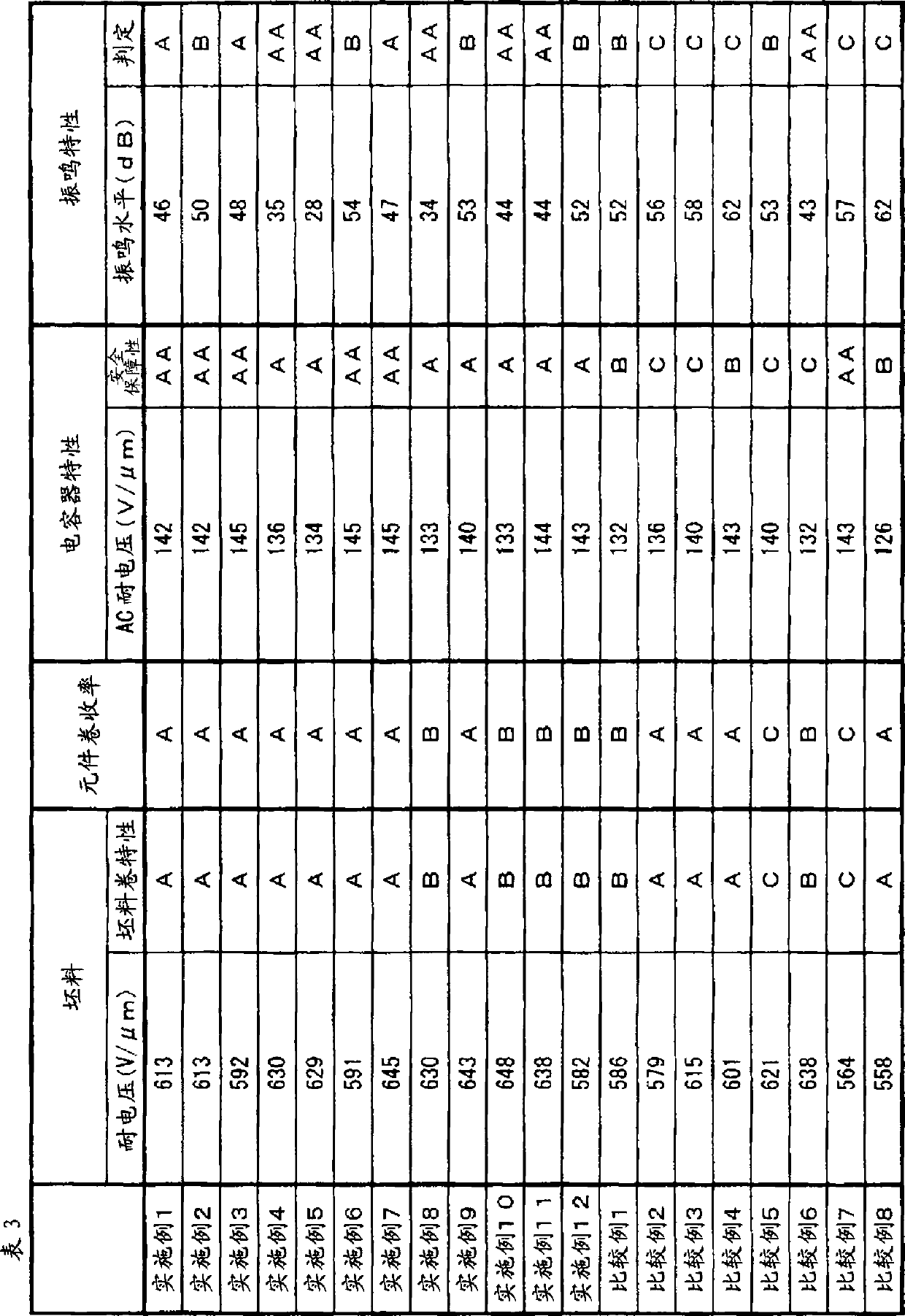

[0202] Film formation was carried out in the same manner as in Example 1, except that the stretching ratio in the longitudinal direction performed after biaxial stretching was 0.5%, to obtain a biaxially oriented polypropylene film. Tables 2 and 3 show properties of the obtained biaxially oriented polypropylene film.

Embodiment 3

[0204] Film formation was carried out in the same manner as in Example 1, except that the cooling drum temperature was 80°C, to obtain a biaxially oriented polypropylene film. The holding time at 115 to 135° C. during cooling and solidification was 2.4 seconds as a result of measurement by a radiation thermometer. Tables 2 and 3 show properties of the obtained biaxially oriented polypropylene film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com