Drilling machine using motors as main power

A technology of active power and drilling rigs, which is applied in the direction of rotary drilling rigs, drilling equipment, earthwork drilling and production, etc. It can solve problems such as the failure of drilling equipment to operate normally, achieve remarkable environmental protection effects, reduce the number of drilling stops, and save energy and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

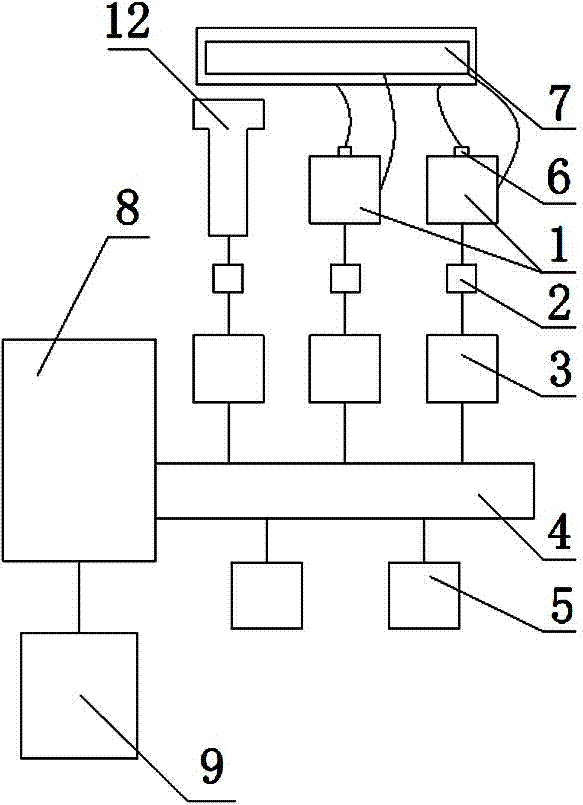

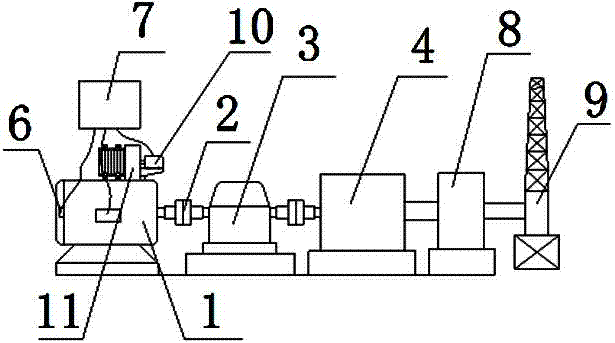

[0018] like figure 1 and figure 2 Shown, a kind of drilling rig with motor as the main power, it includes at least two motors 1, fan 11, shaft coupling 2, hydraulic coupling 3, and carriage 4, drawworks 8, drilling rig 9 and diesel engine 12, motor 1 It is a HTB02C horizontal, single-shaft extension, three-phase squirrel-cage variable-frequency speed-regulating asynchronous motor with double-bearing support structure. A fan 11 is installed on the motor 1. The main shaft of the fan 11 is connected with the main shaft of the fan motor 10. The motor 1 adopts a high-speed High-quality imported bearings and long-term grease have a maintenance-free period of up to three years. The motor adopts forced ventilation and has its own fan 11. The fan 11 is driven by the fan motor 10. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com