Glazed floor board processing technology

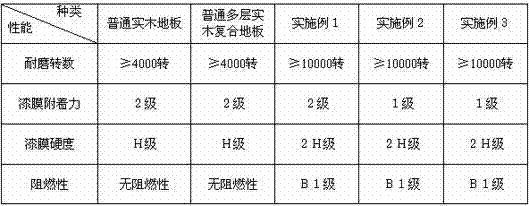

A processing technology and flooring technology, applied in floors, coatings, buildings, etc., can solve problems such as high production and processing costs, inability to use, low adhesion, etc., to prolong life, enhance various performances, and flame-retardant effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A luminous glazed floor processing technology, characterized in that: comprising the following steps:

[0052] (1) Making floor slabs;

[0053] (2) Apply elastic primer, wear-resistant primer and hardened primer to the floor slab obtained in step (1) to obtain floor slab 1;

[0054] (3) Obtain a glazed floor by applying a glaze finish paint to the floor slab obtained in step (2).

[0055] After each painting process, drying treatment is required, and sanding treatment is required after part of the drying treatment process. The detailed steps are as follows:

[0056] Floor slab-elastic primer-infrared drying-sanding-wear-resistant primer-infrared drying-hardening primer-infrared drying-sanding-wear-resistant primer-infrared drying-sanding-infrared drying Drying - sanding - glaze paint - infrared drying - sanding - glaze paint - infrared drying - glaze paint - infrared drying - glaze paint.

[0057] The glaze paint components include: neoprene, red lead, toluene, fume...

Embodiment 2

[0063] The difference from the above-mentioned embodiment lies in the ratio of each component, this embodiment uses multi-layer solid wood composite floor slabs.

[0064] The detailed steps are as follows:

[0065] Floor slab-elastic primer-infrared drying-sanding-wear-resistant primer-infrared drying-hardening primer-infrared drying-sanding-wear-resistant primer-infrared drying-sanding-infrared drying Drying - Sanding - Glaze Finish - Infrared Drying - Glaze Finish - Infrared Drying - Glaze Finish.

[0066] The parts by weight of the glaze paint components are: 13 parts of neoprene rubber, 5 parts of red lead, 2.0 parts of toluene, 2 parts of fumed silica, 1.3 parts of ethyl acetate, 1 part of sulfur, 50 parts of composite resin, plasticizer 6 parts, calcium carbonate 5.0 parts, carbonic acid 4 parts, boric acid 2.0 parts, zirconia 4.5 parts, aluminum powder 5 parts, zinc oxide 2 parts, curing agent 8 parts, titanium white 9 parts, rare earth 0.4 parts, light magnesium oxide...

Embodiment 3

[0070] The difference from the above embodiment is that the floor slab in this embodiment is a solid wood antique floor slab, and the step (1) includes making wood texture grooves on the floor slab. The prepared glazed floor has strong three-dimensional texture and clear texture, and the floor has more natural aesthetics.

[0071] The detailed steps are as follows:

[0072] Floor slab-elastic primer-infrared drying-sanding-wear-resistant primer-infrared drying-hardening primer-infrared drying-sanding-wear-resistant primer-infrared drying-sanding-infrared drying Dry-sanding-glaze paint-infrared drying-sanding-glaze paint-infrared drying-glaze paint-infrared drying-glaze paint-infrared drying-sanding-glaze paint.

[0073] The parts by weight of the glaze paint components are: 12 parts of chloroprene rubber, 4 parts of red lead, 1.7 parts of toluene, 1.7 parts of fumed silica, 1.2 parts of ethyl acetate, 0.8 parts of sulfur, 48 parts of composite resin, plasticizer 5 parts, 4 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com