Bicolor anode titanium film forming method and product

A titanium film, anode technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., to achieve the effects of short manufacturing time, good repeatability, and rich metallic luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

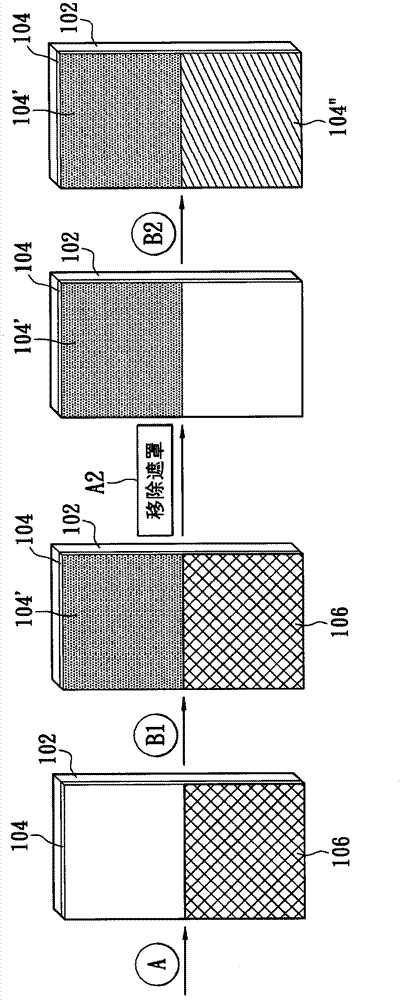

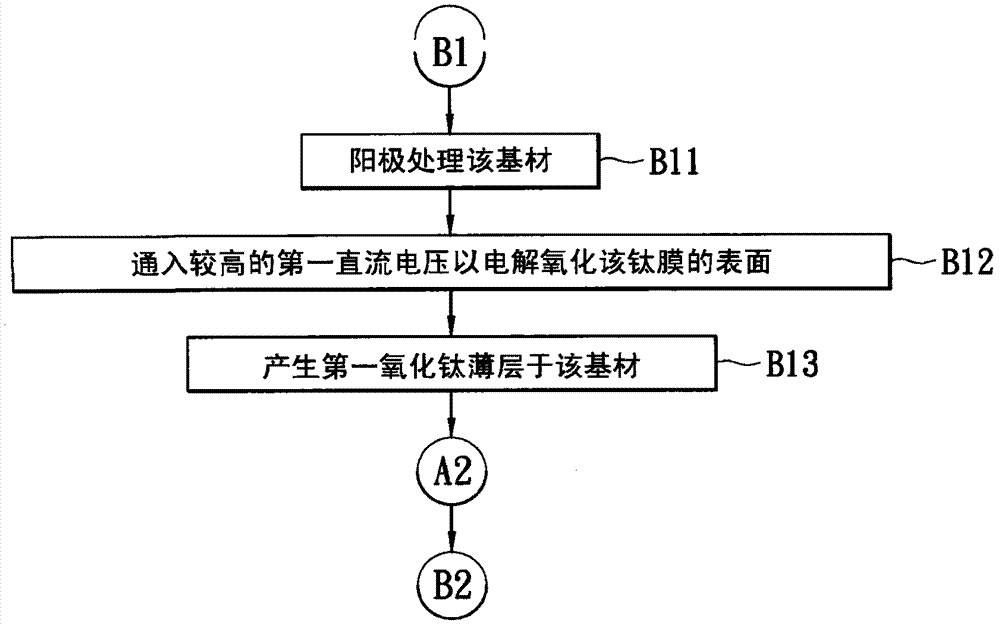

[0028] Please refer to figure 1 , is a schematic diagram of the method for forming a two-color anode titanium film of the present invention. The method for forming a two-color anodic titanium film of the present invention can be divided into a preliminary process A, a first anodizing process B1, a mask removal process A2, and a second anodizing process B2. Each flow will be described below.

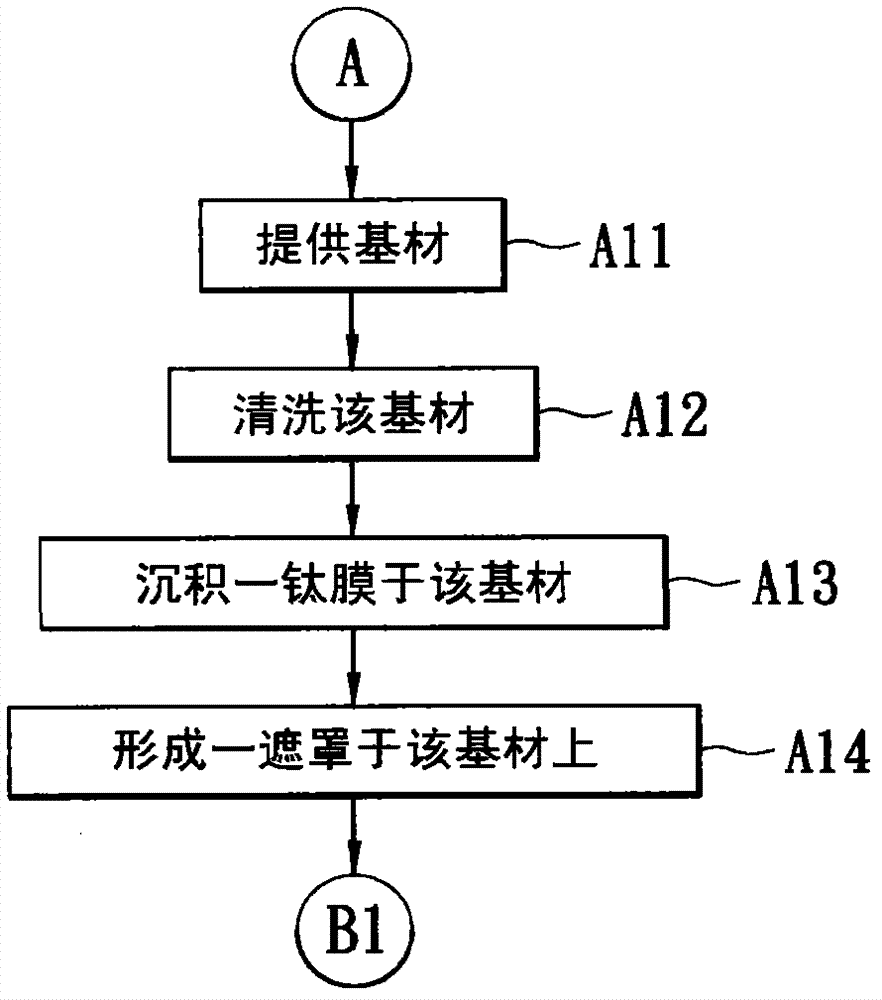

[0029] [Preparation Process A]

[0030] Please refer to figure 1 and figure 2 , figure 2 A schematic diagram of the steps of the preparatory process A of the present invention is shown. In step A11 , a base material 102 is provided. The base material 102 is mainly made of metal, which may be a metal shell, such as aluminum, aluminum alloy, stainless steel or magnesium alloy shell, or even a non-metal shell.

[0031] Next to step A12 , as for the part of the metal casing, the base material 102 needs to be cleaned according to the situation to make it suitable for anodic treatment. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com