Ultrahigh-strength welding structure steel plate and its manufacturing method

A welding structure and ultra-high strength technology, applied in the field of metal materials, can solve the problems of high steel cost, poor low temperature toughness, and high content of precious element Ni in the steel plate, and achieve the advantages of improving hardenability, good plasticity and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment the present invention is further described:

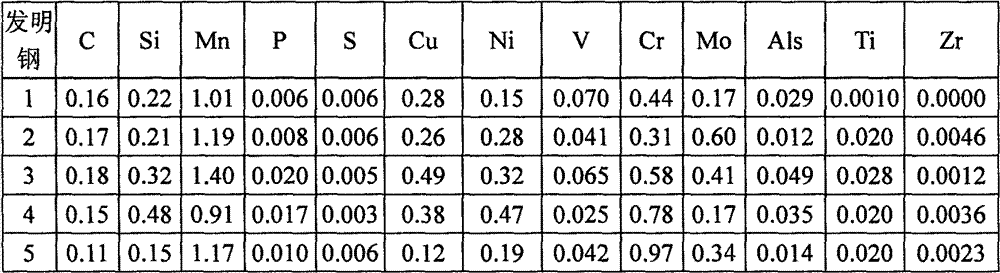

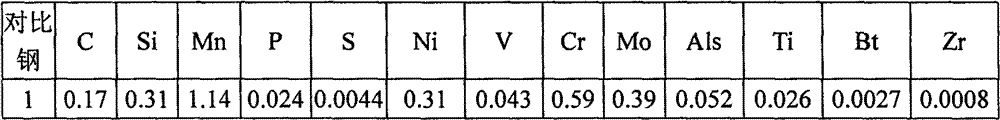

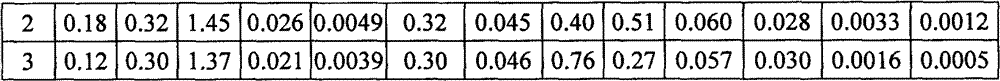

[0025] According to the chemical composition of the present invention and production process, smelting and rolling the steel grade of the present invention and the actual chemical composition of the comparison steel grade are as Table 1 and Table 2, and each embodiment of the invention steel carries out pretreatment of molten iron and deep desulfurization; adopts converter smelting, through Top-blowing or top-bottom combined blowing to control the P content; use VD, RH, LF, etc. for refining treatment, further desulfurization, degassing, control the H, O, N content in the steel, and carry out microalloying; carry out Ca treatment, Combining the S content in the steel and the tapping amount, feed the Si-Ca wire to ensure the Ca / S content Ca / S=0.5~2.0, so that the sulfide can be spheroidized, so as to improve the ductility, transverse impact energy and cold bending performance of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com