Ultraviolet curable monomer and its preparation method, polymerizable composition and backlight module

A technology of polymer composition and ultraviolet light, which is applied in optics, electric light source, organic chemistry, etc., can solve the problems of weak increase of LCD brightness and low refractive index of coating, and achieve good luminance value, high refractive index, The effect of increasing the refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

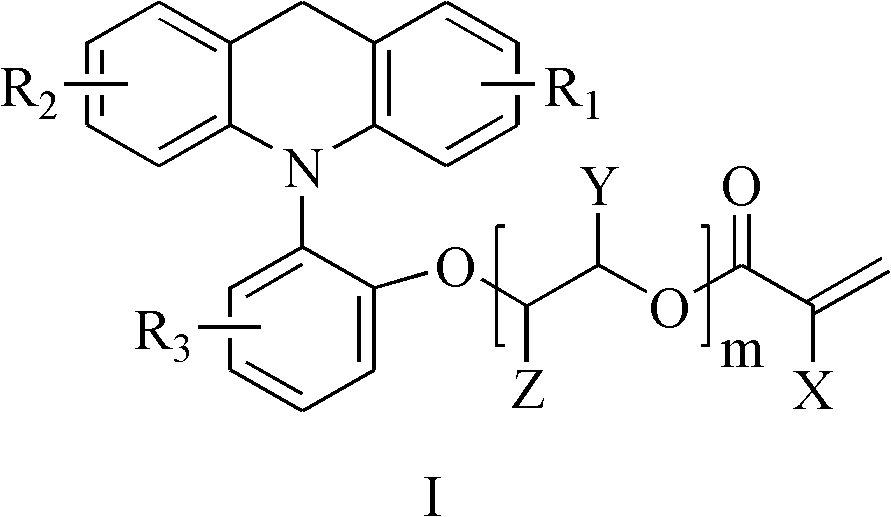

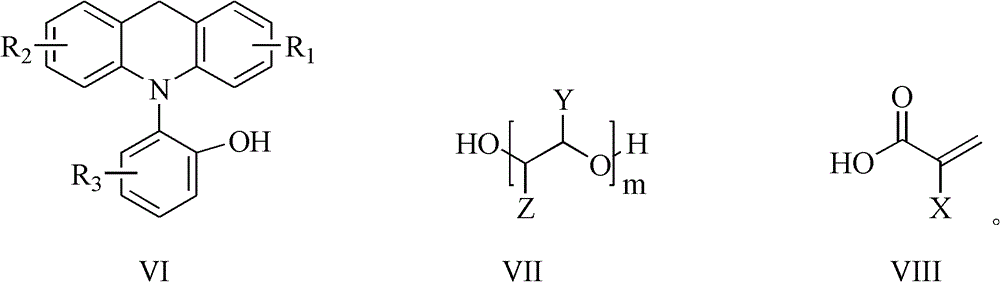

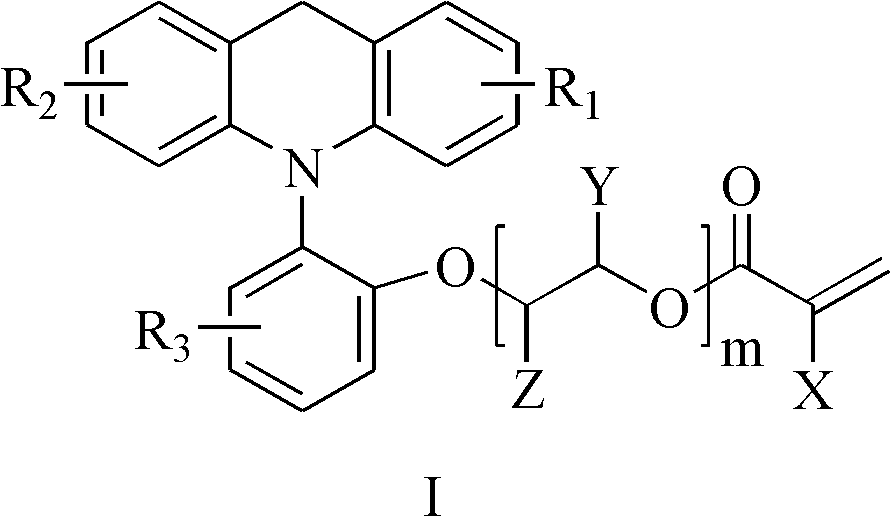

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the polymerizable composition provided by the present invention can be obtained by directly mixing the components in the composition uniformly. Preferably, in order to shorten the mixing time, mixing is preferably performed at 40-80°C.

[0051] Finally, the present invention provides a backlight module, which comprises a lamp tube, a light guide plate and a brightness enhancement film, wherein the brightness enhancement film is formed by curing the polymerizable composition provided by the present invention.

[0052] Among them, the structure of the lamp tube and the light guide plate are well-known to those skilled in the art, and there is no special limitation in the present invention, and will not be repeated. The brightness enhancement film is formed by irradiating and curing the polymerizable composition provided by the present invention under ultraviolet light.

Embodiment 1

[0055] The raw materials used in this embodiment are as follows:

[0056] (a): Compound represented by formula II; react the compound represented by IX (o-hydroxyphenyldihydroacridine) with ethylene glycol in DMF to obtain the pre-product, and then add acrylic acid CH 2 =CH-COOH to obtain the compound represented by formula II.

[0057] (b): Photoinitiator UV307;

[0058] (c): Crosslinking agent SR494;

[0059] (d): Diluent CP-011;

[0060] (e): Additive: 15wt% SiO 2 +40wt% octadecyl dimethyl hydroxyethyl quaternary ammonium salt+15wt% leveling agent BYK-333+15wt% defoamer BYK-018+15wt% lubricant.

[0061] The above-mentioned raw materials were mixed together according to the ratio in Table 1, and heated and stirred at 50° C. to form a uniform and transparent colloidal polymerizable composition S1. The colloidal polymerizable composition S1 prepared above is coated on a polyethylene terephthalate (PET) substrate, and cured by ultraviolet light to form a coating with a prism pattern, and...

Embodiment 2-4

[0063] The polymerizable composition S2-S4 and the brightness enhancement film S22-S44 were prepared using the same steps as in Example 1, except that the distribution ratio of each group is shown in Table 1.

[0064] Table 1

[0065] Component

[0066] Note: In S2, (a) is the compound represented by formula III, which is composed of the compound represented by formula IX and HO-CH 2 -CH 2 -O-CH 2 -CH 2 -OH is reacted with acrylic acid and then prepared; in S3, (a) is a compound represented by formula IV, which is produced by a compound represented by formula X and HO-CH 2 -CH 2 -O-CH 2 -CH 2 -OH is reacted with acrylic acid and then prepared; in S4, (a) is a compound represented by formula V, which is produced by the compound represented by formula XI and HO-CH 2 -CH 2 -O-CH 2 -CH 2 -OH reacted with acrylic acid to prepare.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com