Integration method of wheel pair disassembling and maintaining system for rail locomotive

A rail transit and system integration technology, applied in vehicle maintenance/repair, vehicle maintenance, railway auxiliary equipment, etc., to achieve the effect of good maintenance quality, not easy to lose, and high maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

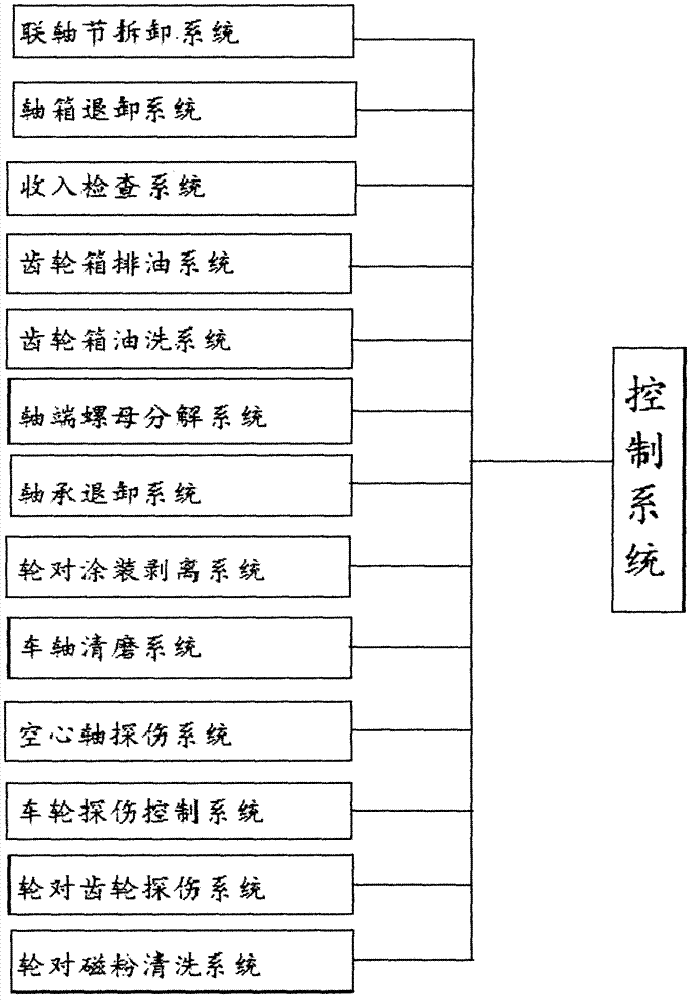

[0056] Such as figure 1As shown, the rail transit locomotive vehicle wheel set disassembly and maintenance system integration method of the present invention includes a control system, a coupling disassembly system connected to the control system, an axle box unloading system, an income inspection system, and a gearbox oil discharge system. system, gearbox oil washing system, shaft end nut decomposition system, bearing withdrawal system, wheel set paint stripping system, axle cleaning system, hollow shaft flaw detection system, wheel flaw detection system, wheel set gear flaw detection system and wheel set magnetic particle cleaning system; the above-mentioned systems are respectively connected with a card reader; and a main switch is also connected with the management system and the above-mentioned systems respectively.

[0057] Coupling dismantling system for dismantling of wheel set shaft end parts and couplings;

[0058] Bearing unloading system, used for dismantling and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com