Sulfur chlorinated isobutylene production equipment and method

A technology for sulfur-chlorinated isobutene and production equipment, which is applied to the field of reaction equipment for sulfur monochloride and isobutene, can solve the problems that the reaction equipment is difficult to use, the reaction conditions of sulfur monochloride and isobutene are difficult to control, etc., and the reaction temperature is easy to control. , The amount of by-products is reduced, and the effect of overcoming low toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

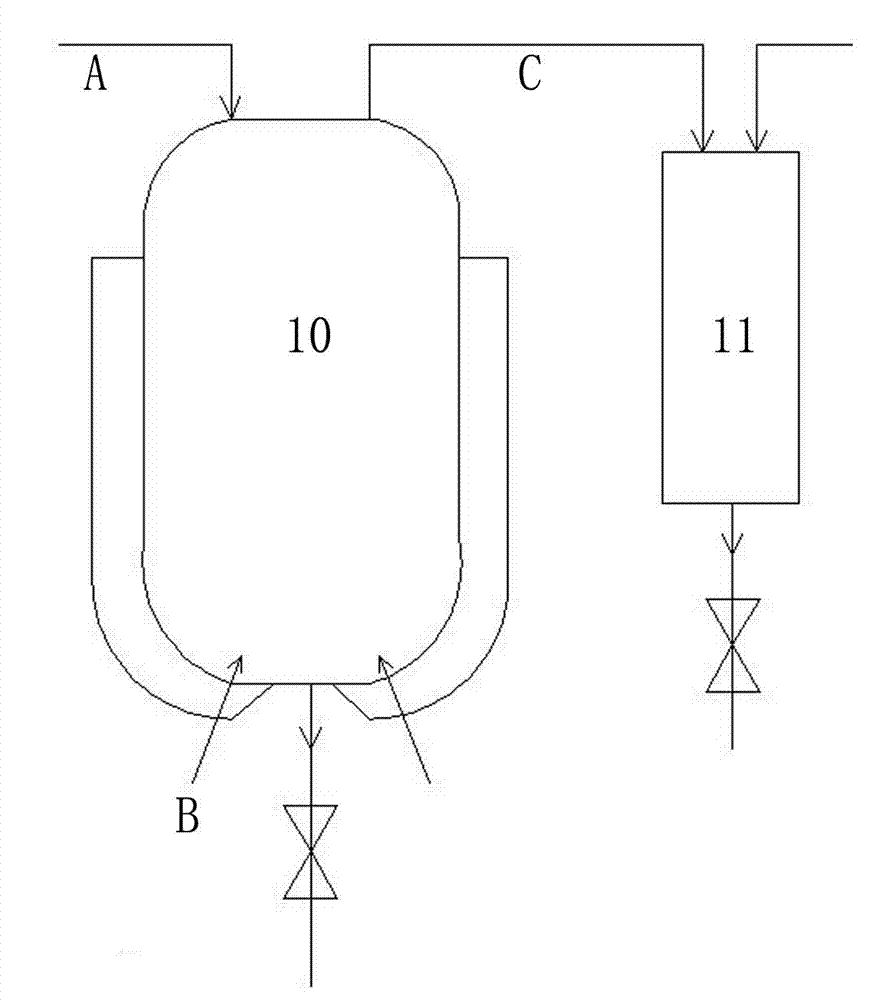

[0021] refer to Figure 1 to Figure 3 , a kind of sulfochlorinated isobutylene production equipment of the present invention, comprises enamel gas-liquid reactor 10 and falling film absorption tower 11, and described enamel gas-liquid reactor comprises upper head, kettle body, stirring shaft 5, on stirring shaft 5 There is a stirring blade 8, a jacket 3 is provided outside the kettle body, a coolant inlet 2 and a liquid outlet 7 are provided on the jacket 3, the upper head is connected with the kettle body, and the upper part of the kettle body is provided with a feed port 4. The exhaust port 6, the exhaust port 6 is connected with the falling film absorption tower 11, the bottom center of the kettle body is provided with a discharge port, and the bottom of the kettle body is provided with an air inlet pipe 1, which is evenly distributed coaxially around the discharge port 9 Three intake pipes 1; the aspect ratio of the kettle body is 2~3.5:1, and the volume of the kettle body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com