Production method of nutritional rice with good cooking performance and storability

A nutritional rice and cooking technology, which is applied in the directions of heating and preserving seeds, edible seeds, and seeds through radiation/electrical treatment, etc., can solve the problems that insect eggs cannot be eradicated, rice slow oxidation, etc., and achieve improved cooking performance , Improve the killing effect, the effect of smooth and uniform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

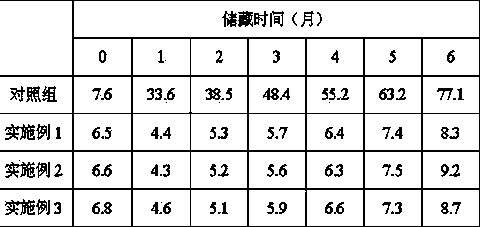

Examples

Embodiment 1

[0011] The husked and impurity-removed fresh brown rice is subjected to multi-stage light milling, specifically: after being roughened by a 46-mesh fine emery roller at a low speed (the speed is 700 rpm), the brown rice is subjected to three-stage low-speed grinding with an 80-mesh fine emery roller. Light milling (spindle speeds are 900 rpm, 1000 rpm, 1000 rpm respectively), and the brush polishing wheel removes floating chaff on the surface of rice grains to obtain nutritious rice.

[0012] Microwave and hot air combined treatment of nutritious rice: (1) Slowly add water by atomization until the water content of nutritious rice is 19%, and keep adding water at a rate of 0.6% / hour before the water reaches 17%, and will add water after it exceeds 17% Slowly increase the speed to 1.0% / hour; (2) Use microwaves to treat nutritious rice, the microwave frequency is 2450±50MHz, the power is 300 watts, and the processing time is 30 seconds; Suspension for 20 minutes in a 75% environm...

Embodiment 2

[0014] The husked and impurity-removed fresh brown rice is subjected to multi-stage light grinding, specifically: after being roughened by a 46-mesh fine sand roller at a low speed (800 rpm), the brown rice is subjected to three-stage low-speed grinding with a 70-mesh fine sand roller. Light milling (spindle speeds are 800 rpm, 800 rpm, 800 rpm respectively), and the brush polishing wheel removes floating chaff on the surface of rice grains to obtain nutritious rice.

[0015] Combined microwave and hot air treatment for nutritious rice: (1) Slowly add water by atomization until the water content of lightly milled nutritious rice is 18%, and keep adding water at a rate of 0.6% / hour before the water reaches 17%, and after it exceeds 17% Slowly increase the rate of water addition to 0.9% / hour; (2) Use microwaves to treat the nutritious rice, the microwave frequency is 2450±50MHz, the power is 350 watts, and the processing time is 25 seconds; (3) The microwave-treated nutritious ri...

Embodiment 3

[0017] The husked and impurity-removed fresh brown rice is subjected to multi-stage light grinding, specifically: after being roughened by a 46-mesh fine emery roller at a low speed (1000 rpm), the brown rice is subjected to three-stage low-speed grinding with a 60-mesh fine emery roller. Light milling (spindle speeds are 700 rpm, 600 rpm, 600 rpm) and brush polishing wheels to remove floating chaff on the surface of rice grains to obtain nutritious rice.

[0018] Combined microwave and hot air treatment for nutritious rice: (1) Slowly add water by atomization until the water content of lightly milled nutritious rice is 17%, and keep adding water at a rate of 0.6% / hour before the water reaches 17%, and after it exceeds 17% Slowly increase the water adding rate to 0.8% / hour; (2) Use microwaves to treat nutritious rice, the microwave frequency is 2450±50MHz, the power is 400 watts, and the processing time is 20 seconds; (3) The microwave-treated nutritious rice is heated at 25°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com