Double-electrode structure field emission luminous tube capable of regulating and controlling luminous patterns

A luminescent pattern and double-electrode technology, applied in discharge tubes, electrode devices and related components, cathode ray tubes/electron beam tubes, etc., can solve the problems of complex structure, high production cost, and inability to adjust and control, and achieve High luminous efficiency, low cost, and good pattern control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

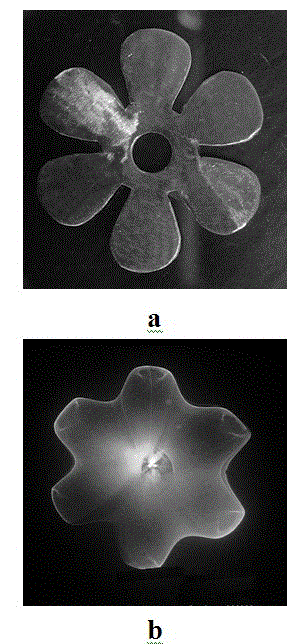

[0020] Illuminated control components and display graphics such as figure 2 shown.

[0021] A carbon nanotube rope with a macroscopic length is used as a field emitter with an effective height of 2.5 mm and a diameter of 100 μm. The display pattern control component is made of two pieces of sodium-aluminosilicate glass 1, with a single piece size of 12x8 x 1 (mm), symmetrically arranged on both sides of the field emitter 2, with a distance of 6 mm; the flat anode is made of ITO conductive glass, coated with There is a phosphor film; the distance between the tip of the field emitter and the ITO anode is about 1 mm. In the working state, the applied voltage (positive potential) is applied to the ITO anode, and the field emitter is grounded. When the applied voltage is lower than 550V, the display pattern is in the shape of circular spots; when the applied voltage is higher than 570V, the display pattern is determined by the outer contour of the control component, which is clo...

Embodiment 2

[0023] The difference from Example 1 is that an external voltage (negative potential) is applied to the field emitter, and the ITO anode is grounded. The display pattern form is the same as in Example 1.

Embodiment 3

[0025] The body of the field emitter is a copper filament with an effective height of 5.0 mm and a diameter of 200 μm. There is a carbon nanotube film on the top surface. The display pattern control component is made of two ceramic plain sheets with a single piece size of 12 x 10 x 3 (mm), symmetrically arranged on both sides of the field emitter with a distance of 6 mm; the flat anode is made of ITO conductive glass, coated with Phosphor film; the distance between the field emitter tip and the ITO anode is about 0.5 mm. In the working state, the applied voltage (negative potential) is applied to the field emitter, and the ITO anode is grounded. When the applied voltage is higher than a certain potential difference, the display pattern changes from a circular spot to an approximate rectangle, similar to the outer contour of the control component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com